- 電子部品関連

高電圧電気自動車(EV)の未来:バッテリー性能と安全対策の重要性

近年、コネクティッド、自動化、シェアリング、電動化といった「CASE」と呼ばれる技術革新が進むなかで、特に電動化を象徴する電気自動車(EV)は注目を集めています。電気自動車の普及は、持続可能な社会の実現に向けた重要なステップとなっていると言えるでしょう。本記事では、電気自動車におけるリチウムイオン電池の役割、バッテリーの高電圧化の背景とその安全対策について、デクセリアルズのソリューションを交えながら詳述します。

電気自動車(EV)の普及状況

電気自動車の普及は、SDGsや環境への配慮、二酸化炭素削減の流れから各国で補助金が支給されることで加速しています。政府の強力な政策支援に加え、消費者の環境意識の高まりも電気自動車市場の拡大を後押ししています。また、北米や中国、東南アジアの新興電気自動車メーカーが日本を含めた各国市場に参入していることも普及を促進する要因となっています。このような背景から、モーターショーやディーラー、イベント、ショッピングモールの特設スペースなどで電気自動車を見る機会も増えました。

電気自動車は電池とモーターで動くため、エンジン車と比較して車内外の静粛性が高く、排気ガスを出さない点で環境に優しい車と言われています。最近では補助金支給もあることから、本体価格の高さを相殺し、一般消費者にとっても購入しやすくなってきました。国際エネルギー機関(IEA)の発表によれば、2023年、世界の電気自動車(乗用車のみ)の新車販売台数は、前年比35%増の約1,400万台に達しています*。特に中国は電気自動車の販売が810万台と突出して多く、次いで欧州が330万台、米国が139万台と続きます。中国は世界の電気自動車販売の60%近くを占めており、次いで欧州、米国が続いています。

*出典:Trends in electric cars – Global EV Outlook 2024 – Analysis – IEA

電気自動車(EV)におけるリチウムイオン電池

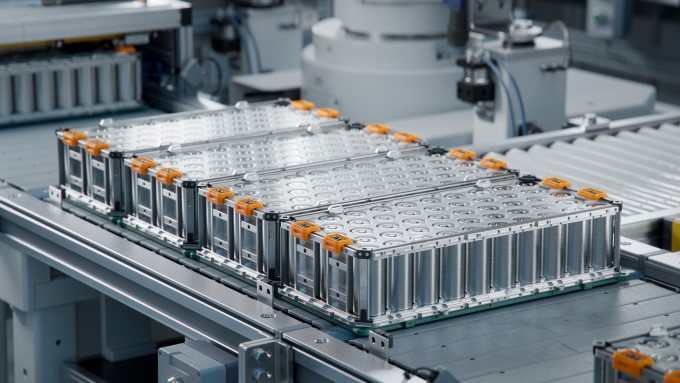

急速に成長する電気自動車市場のなかで、リチウムイオン電池を使用したバッテリーパックは重要な役割を果たしています。電池性能の向上は航続距離、重量、充電コストに直結しており、自動車メーカーは各社独自の設計手法で差別化を図っています。

初期の市場では、角型バッテリーパックを使った電気自動車が主流でした。しかし、その後、北米の電気自動車メーカーが数千個の円筒型リチウムイオン電池を接続してバッテリーパックを設計し、市場で大きく普及したことから、各社が独自の設計手法で差別化を図るようになりました。最近では、中国のメーカーがブレード型のバッテリーを採用するなど、さまざまな形状や設計が試みられています。

リチウムイオン電池の技術進化は目覚ましく、エネルギー密度の向上、充電速度の短縮、寿命の延長が求められています。例えば、固体電解質を用いた全固体電池は、従来のリチウムイオン電池に比べて安全性が高く、エネルギー密度も向上することが期待されています。これにより、電気自動車の航続距離をさらに伸ばすことが可能となります。

また、電池の設計においては、セルの配置や冷却システムの効率化も重要な要素です。セルの配置によりエネルギー密度を最大化しつつ、冷却システムによって適切な温度管理を行うことで、バッテリーの寿命を延ばし、安全性を確保します。これらの技術的進展により、電気自動車の性能はますます向上しています。

車載バッテリーの800V高電圧化

現在、電気自動車の中には電池電圧を従来の400Vから800Vに高めるモデルも登場しています。これにより、充電時間の短縮や航続距離の延長が可能になります。800V高電圧化で、充電インフラの効率が向上し、ユーザーの利便性が大幅に改善されます。

800V高電圧化のメリットとして、以下の点が挙げられます。

- 充電時間の短縮: 800Vシステムでは、約20分で航続距離400kmを確保することが可能

- 動力性能の向上: 高電圧により駆動モーターの小型・軽量化が可能

- 充電インフラの効率化: 高電圧により同じエネルギーを伝送するために必要な電流が減少し、これによりケーブルの発熱を抑え、充電器の効率も向上

電気自動車の航続距離は、一般的なガソリン車と遜色ない400~500kmを確保することが目標となっています。高電圧化により、急速充電が可能となり、短時間で十分な航続距離を確保することができます。また、電圧を高めることで、電流を抑え、ケーブルの発熱量を小さくすることができ、電線を細く軽くしやすくなります。これにより、車両全体の効率も向上し、航続距離がさらに伸びる可能性があります。

一方、充電インフラ側も800Vへの対応が必要とされています。欧州では800V対応の出力が150kWと大きい充電器が設置されはじめており、これが主流になりつつあります。日本では50kW(400V・125A)の充電器が主流ですが、充電規格では400kW(1000V・400A)に対応しているものも出てきています。こうしたことからも、日本や中国ではEVの800V化を進める基盤が整いつつあると言われています。これに対して、北米ではやや充電インフラの普及が停滞している状況です*。

*参照:SBD Explores: EVの800V化の動向、自動車メーカーはこれを採用すべきか?

800V高電圧化に伴う課題とデクセリアルズのソリューション

しかし、800V高電圧化には、安全性の確保といった課題が残ります。高電圧下では、絶縁破壊やアーク放電のリスクが増加し、それに伴う火災や爆発の危険性も高まります。したがって、適切な絶縁材料の使用や高度な安全機構の導入が不可欠です。

現在、デクセリアルズでは、800V対応の二次保護ヒューズの開発を進めています。この新製品は、電気自動車メーカー各社のビジネスを加速し、モビリティの進化を支えるものです。高電圧化する電気自動車の普及に伴い、安全対策がますます重要となるなか、私たちのソリューションはその課題を解決するものとなるでしょう。

詳細な情報や技術的なサポートについては、ぜひお問い合わせください。エンジニアの皆さまからのご連絡をお待ちしております。

関連記事

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら