- 接合関連

ディスプレイの進化とそれを支える異方性導電膜(ACF)

目次

ディスプレイ技術の進化と異方性導電膜(ACF)の役割

現代社会において、薄型ディスプレイはスマートフォンやタブレット、テレビ、パソコンといったさまざまなデバイスに組み込まれ、私たちの生活に欠かせない存在となっています。これらのデバイスに使われているディスプレイ技術は、登場以来、目覚ましい進化を遂げてきました。この進化の背後には、デクセリアルズの異方性導電膜(ACF)が重要な役割を果たしていることは、あまり知られていないかもしれません。

ACFは、ディスプレイ技術の発展に不可欠な要素として、LCDやOLED、さらにフレキシブルOLEDといった最新のディスプレイ技術を支えてきました。この記事では、ディスプレイ技術の進化の歴史と、それを支えるACFの重要性について詳しく解説します。

液晶ディスプレイ (LCD) の発展とACFの貢献

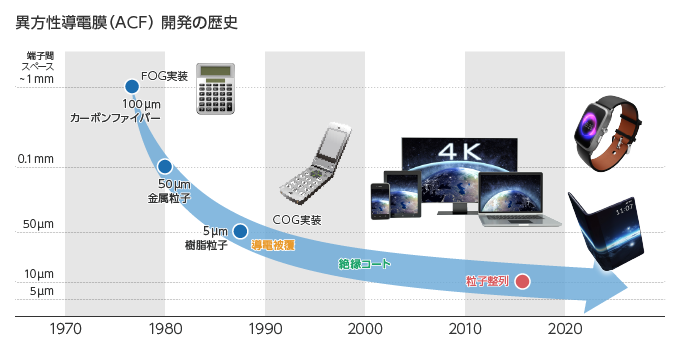

液晶ディスプレイ(LCD)の歴史は、1960年代に液晶の表示原理が発見されたことに始まります。1970年代には電卓や腕時計などに応用され、1990年代に入ると、ノートPCやテレビ、モニターといったより大型のディスプレイにも採用が進みました。

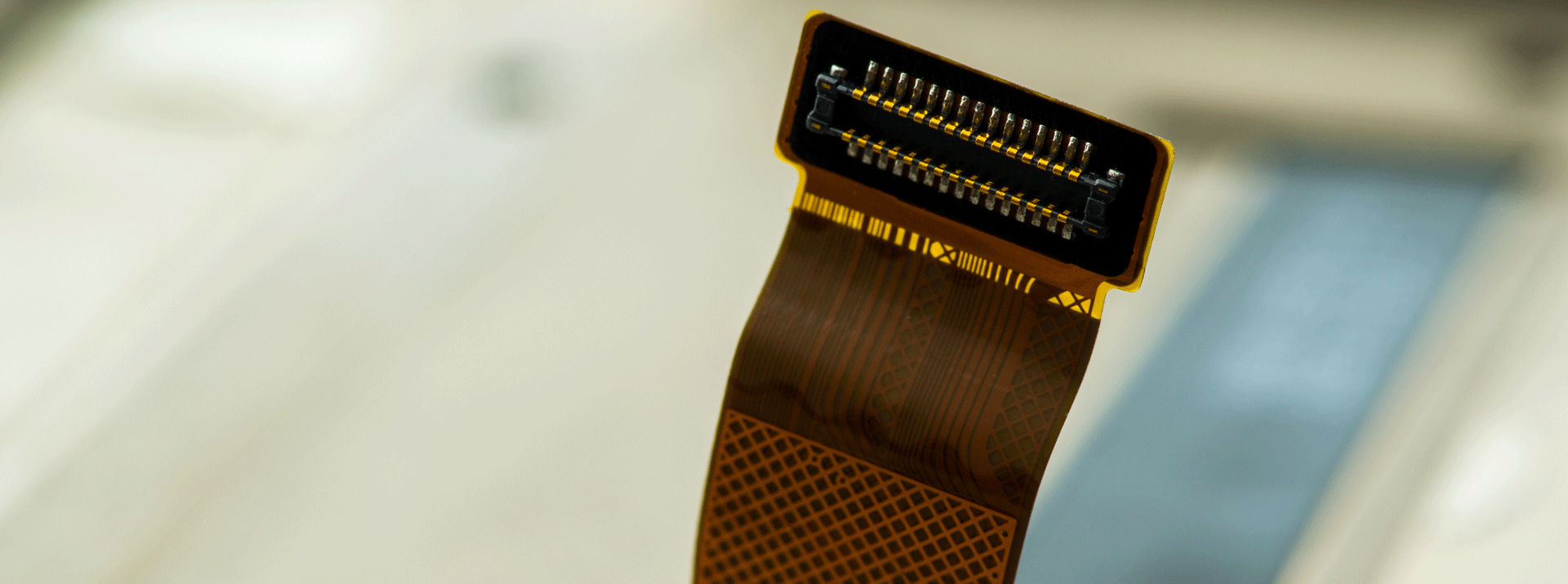

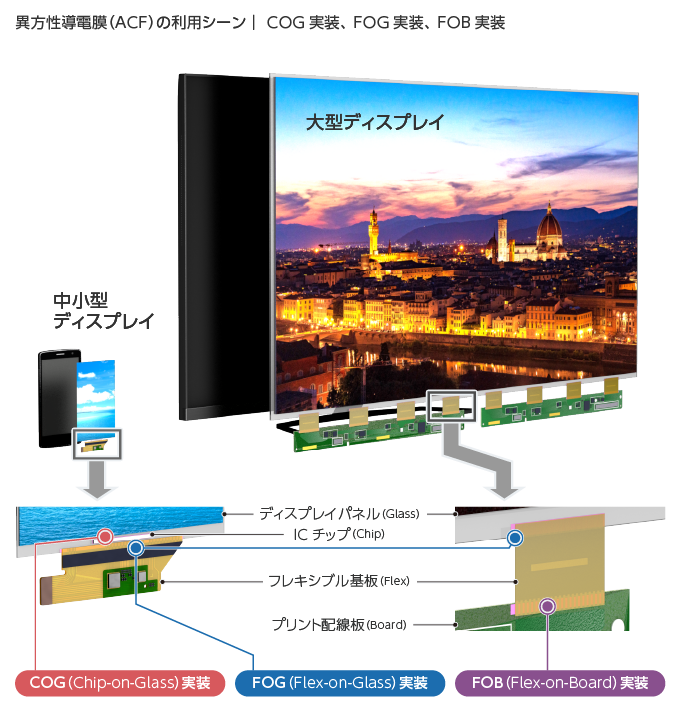

LCD技術の進化において特に重要だったのは、ディスプレイの薄型化と高解像度化でした。ACFは、ディスプレイの進化を支える信頼性の高い回路接続を実現しています。接続部の薄型化に貢献しつつ、確実な接着/高い接続信頼性/隣接回路との絶縁性を兼ね備えています。被着体の種類も豊富であり、TCP(Tape Carrier Package)やCOF(Chip on Film)パッケージの信号出力電極とディスプレイの接続、さらにCOG(Chip on Glass)方式でのドライバIC実装にも適用することができます。

ACFの普及により、高解像度を実現する回路の微細化を可能にし、駆動ICの小型化によりデバイスの薄型・軽量化にも貢献してきました。LCD技術は液晶の表示原理が発見されてから急速に発展しましたが、ACFの技術進化がなければ、現在の薄型で高解像度なディスプレイは実現できなかったかもしれません。

有機ELディスプレイ (OLED) の登場とACFの技術対応

LCD技術の進化が進むなか、次世代ディスプレイ技術としてOLEDが登場しました。1987年、イーストマン・コダック社がOLEDの基本原理を発表し、自己発光型の素子を使用することで、従来のLCDを超える高コントラスト、広視野角、薄型、軽量といった特性を持つディスプレイ技術を実現しました。しかし、当初は製造コストの高さや技術的課題から普及が遅れていました。

OLEDの普及が遅れた主な要因として、製造コストの高さ、青色有機EL素子の短寿命、そして静止画の長時間表示による焼き付き(バーンイン)などが挙げられます。さらに、OLEDの製造プロセスは複雑であり、歩留まりが低かったため、大規模な生産が難しいとされていました。

しかし、2000年代後半に入り、スマートフォンやデジタルカメラなどの小型ディスプレイにおいてOLEDが採用され始め、技術的な課題が徐々に解決されると、OLEDの特性が評価され、大型テレビやフレキシブルディスプレイにも応用が広がりました。この時期、ACFはOLED特有の電気特性と配線設計に対応すべく、さらに進化を遂げました。

フレキシブルOLEDとACFの技術革新:Flex on Plastic(FOP)とChip on Plastic(COP)の実現

フレキシブルOLEDは、ポリイミド基板の使用により、ディスプレイが柔軟で耐久性に優れ、折り曲げ可能なデザインを実現しました。この技術は、フレキシブルディスプレイや、ウェアラブルデバイスにおいて、革新的なデザインが可能となりました。しかし、このようなデザインを実現するためには、柔軟な基板との接続において、高い導通信頼性を維持するという技術的な課題を克服する必要がありました。

この課題を克服するために、「Flex on Plastic(FOP:プラスチック基板に柔軟なFPCを直接実装する技術)」や「Chip on Plastic(COP:プラスチック基板上に硬いICを実装する技術)」といった技術が開発されました。これらの技術では、柔らかいプラスチック基板と硬いドライバICの間で確実な接続を実現するために、ACFが重要な役割を果たしています。デクセリアルズが新たに開発した「ArrayFix」は、粒子が整列したACFで、極小面積での接続信頼性と狭い隣接電極間の絶縁性を両立でき、不安定な接続領域でも高精細で信頼性の高い接続を実現しており、フレキシブルOLEDの性能向上に大きく貢献しています。

関連記事:粒子整列型異方性導電膜「ArrayFIX」の基礎知識

ACFの技術的特徴とディスプレイ技術への貢献

ACFは、LCDやOLED、そしてフレキシブルOLEDなどの高精細ディスプレイ技術を支える重要な接続技術です。その特徴として、100μmピッチ以下の微細接続が可能であり、さまざまな配線材料に対応する柔軟性を持っています。ITO電極や金属配線など、さまざまな配線材料に対応することで、LCDからOLED、さらにはフレキシブルOLEDに至るまで、ディスプレイ技術の高精細化や高性能化を支えています。

さらに、ACFの技術進化は先述のArrayFixにも見られます。この粒子をきれいに整列させる技術により、配線材料やピッチに合わせた最適な接続が可能となり、ディスプレイの性能向上に寄与しています。FOPやCOP技術においても、ACFは高精度な接続を実現し、フレキシブルOLEDの普及と進化に不可欠な存在となっています。

関連記事

・粒子整列型異方性導電膜「ArrayFIX」 そのメリットと拡大する市場

・粒子整列型異方性導電膜「ArrayFIX」――整列に隠された秘密

ACFが未来のディスプレイ技術を支える

ディスプレイ技術の進化は、LCDからOLED、そしてフレキシブルOLEDへと続きますが、これらの技術革新を支える要素として、常に異方性導電膜(ACF)の技術的貢献がありました。ACFは、ディスプレイの高精細化、デザイン性の向上、そして信頼性の高い接続を実現するために不可欠な要素です。

こうして、さまざまなディスプレイ技術においても、ACFは信頼性の高い回路接続を実現し続け、その発展を支えてきました。今後も、デクセリアルズのACFはマイクロLEDやシリコンOLEDなど、次世代のディスプレイ技術を支え、私たちの生活を豊かにする製品の実現に寄与していきます。

関連記事

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら