- 光学関連

モスアイ構造を応用した反射防止フィルム 車載ディスプレイへの展開

車載ディスプレイへの活用が進むモスアイフィルム

ディスプレイ等の反射を防止し、視認性を向上させる機能を持つフィルムや樹脂は、現在デクセリアルズの主力製品カテゴリーの一つとなっています。当社の反射防止フィルムAR100シリーズは、ディスプレイカバーに貼ることで光の反射と拡散を抑える高い効果を実現することから、モニターやタブレットPC、車載ディスプレイなどを製造する数多くのメーカーに採用されてきました。

またディスプレイ製品の表面板(トッププレート)とディスプレイモジュールを貼り合わせる光学透明な樹脂(OCR/LOCA)も、材料境界での光の反射・屈折を抑制する材料です。デクセリアルズではこの分野の製品として「光学弾性樹脂(SVR)」および「光学弾性樹脂(SVR)ハイブリッドタイプ」と呼ばれる商品を発売しています。

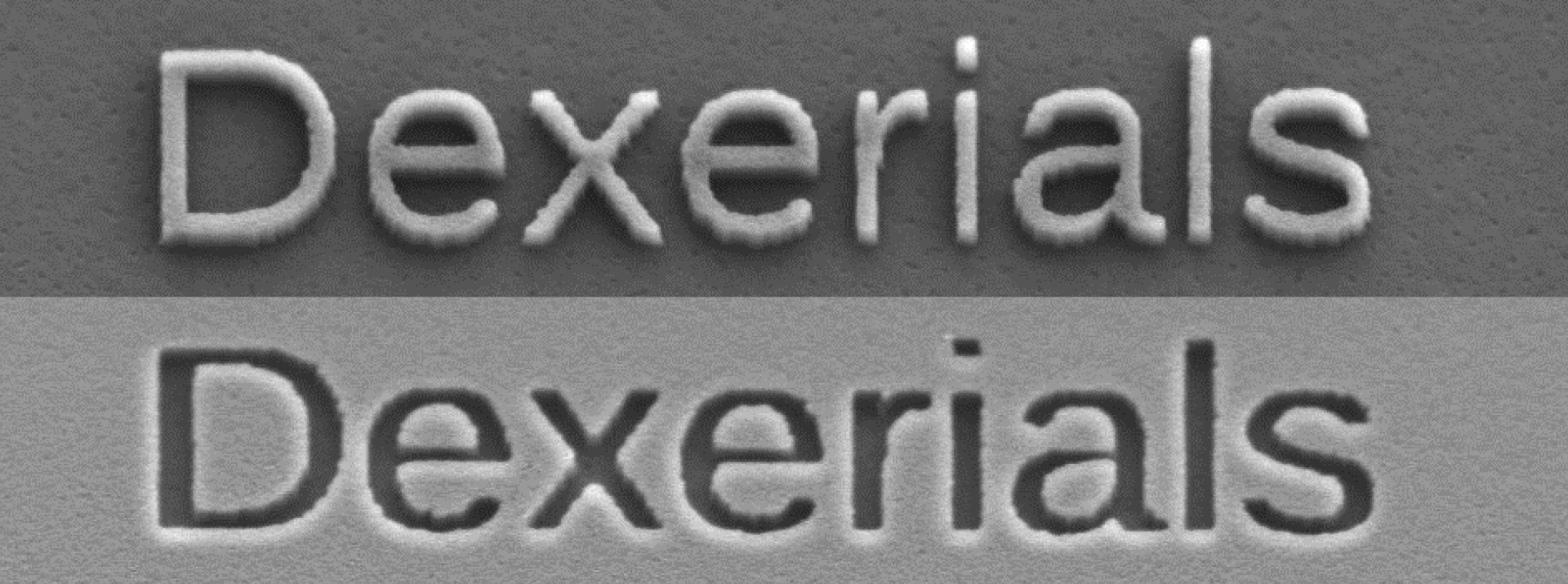

近年その光学分野の製品群に新たに加わったのが、「反射防止フィルム モスアイタイプ」です。モスアイ(Moth-eye)とは昆虫の蛾の眼を意味します。蛾の眼の表面にはナノレベルの突起が規則正しく並んでおり、その構造によって入ってくる光をほとんど反射せずに眼の内部に取り込むことができます。デクセリアルズでは、独自の製法によって樹脂フィルム上に蛾の眼と同様の構造を作ることに成功。これをディスプレイ等に貼ることで、高い反射防止効果とコントラスト向上を実現する技術を確立しました。

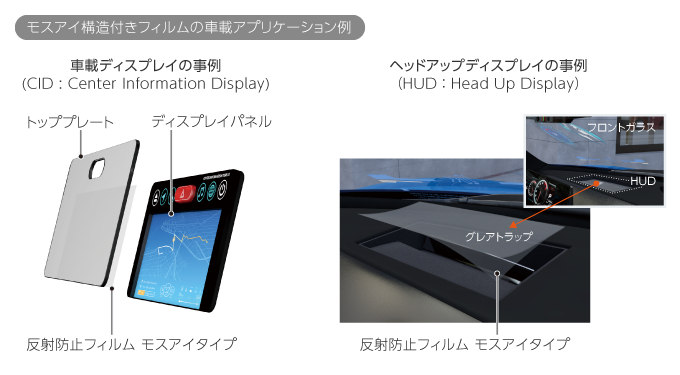

その反射防止フィルム モスアイタイプの活用の場として近年活用が進むのが、車のダッシュボードに設置されて自動車の位置情報などを映し出す「センターインフォメーションディスプレイ(CID)」と、運転席前のフロントガラスなどに車速などの情報を投影する「ヘッドアップディスプレイ(HUD)」の2つです。

反射防止フィルム モスアイタイプとOCRの比較

以下は、CIDに反射防止フィルム モスアイタイプを利用した際の模式図になります。画像を表示するフラットパネルディスプレイ(FPD)を保護するトッププレートの裏側にモスアイフィルムを貼ることで、トッププレート内面での光の反射を防止します。FPDとトッププレートの間に空間があると、空気とプレートの境界で反射や散乱が起きて画像ボケの原因となります。一つの対策は当社のSVR・ハイブリッドSVR等のOCRで空隙(エアギャップ)を埋めることですが、デザイン上の都合やエアギャップが大きいなど、さまざまな理由からOCRが使えない場合があります。こういった場合には、反射防止フィルム モスアイタイプを貼ることでOCRに近い効果が得られます。

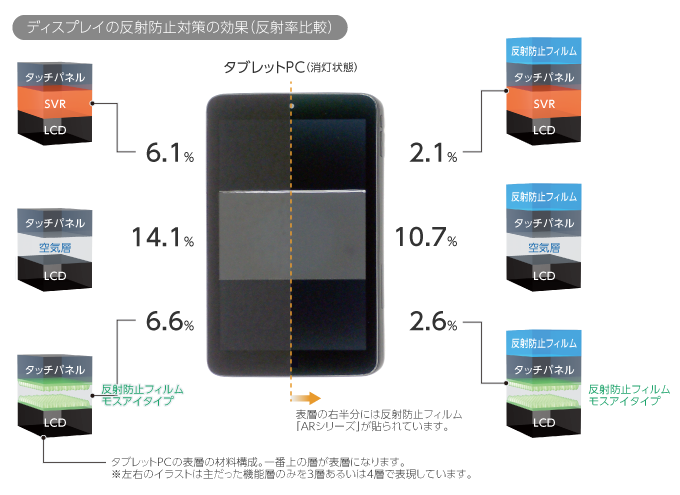

下記はタブレットPCのディスプレイの表示領域を6つに分けて構造(反射防止対策)の違いによる反射の状態とコンストラストの違いを 示したデモンストレーションになります。まず、タッチパネルとLCD間の内部構造に関してですが、上から順にエアギャップに対して、「隙間を光学弾性樹脂(SVR)で埋めた」「対策なし」「内面に反射防止フィルム モスアイタイプを貼った」の3種類になります。これをさらに外表面への反射防止フィルムのあり(右側)・なし(左側)で分けて6種類の領域を作っています。また表示の数値は各領域の反射率を表しています。表層に反射防止フィルムを貼り、さらに内部をSVRで埋めた構造が最も反射率が小さくなりますが、それに続くのがモスアイタイプを内面に貼った領域となり、OCRに近い効果が得られていることが分かります。同時に反射防止対策を行わない領域は画面が白っぽくなり視認性が落ちていることから、反射防止対策の重要性も理解いただけると思います。

反射防止フィルム モスアイタイプと、光学弾性樹脂(SVR)がそれぞれ適しているディスプレイデザインですが、トッププレートとディスプレイ間のエアギャップが比較的小さい場合にはSVRが向いています。これに対し、エアギャップが0.5mm以上と大きい場合には反射防止フィルム モスアイタイプが適しています。近年のカーナビゲーションシステムでは2.5Dまたは3Dの曲面タイプの形状が増えてきており、トッププレートやディスプレイモジュールがカーブを描いていても、ある程度まで反射防止フィルム モスアイタイプは対応が可能となっています。

モスアイフィルムでHUDの二重像(ゴースト)対策

モスアイ構造付き反射防止フィルムの自動車における活用法の一つが、近年増えている運転席側のフロントガラスに運転情報を投影するヘッドアップディスプレイ(HUD)への採用です。HUDはドライバーの視線を前方に保ったまま、速度やエンジン回転数、ナビゲーション情報などを目視できることから、高級車を中心に搭載する車種が増えています。

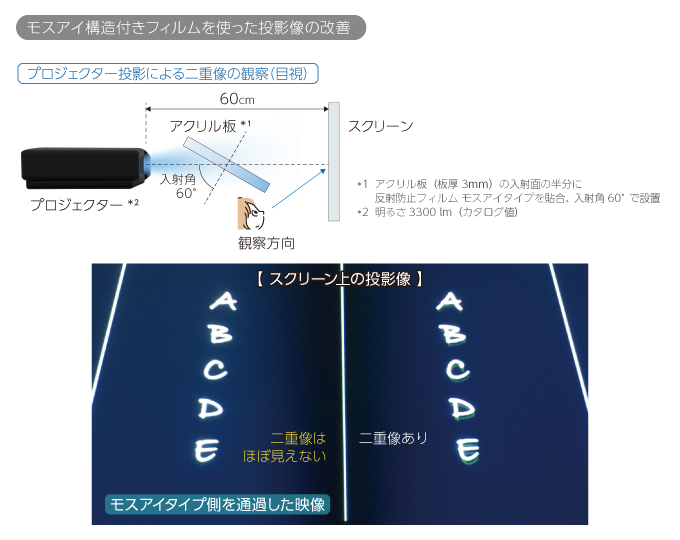

HUDの投影機構は大まかに、光を出射するプロジェクター部と反射鏡、光のぎらつきを抑える透明なグレアトラップと呼ばれる透明板で構成され、グレアトラップ以外はダッシュボードの中に収まっています。グレアトラップの厚みは0.4〜0.5mmほどで、光が透過する際にグレアトラップと空気との屈折率の違いから入射面と出射面のそれぞれで反射が起こり、フロントガラスに映し出される像が二重に見える場合があります(ゴースト現象)。HUD用のモスアイフィルムをグレアトラップの裏面(投影光の入射面)に貼ることで、裏面での反射率がおよそ4%から0.3%程度に抑えられ、ゴースト現象をかなり抑制することが可能になります。以下の図はゴースト現象を説明するための実験の様子です。

近年、自動車に搭載されるディスプレイは従来のダッシュボードの場所以外にも増え続けており、サイドミラーやバックミラーの映像を映し出す新たなディスプレイシステムが続々と開発されています。ドライバーの視認性を向上させ、安全性にも寄与できる車載用モスアイフィルムの活用の場はこれからも広がっていきます。

関連記事

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら