- Electronic Components

The different types of TIMs (Thermal Interface Materials)

Updated: August 10, 2023

Contents

Types of TIMs used for heat dissipation

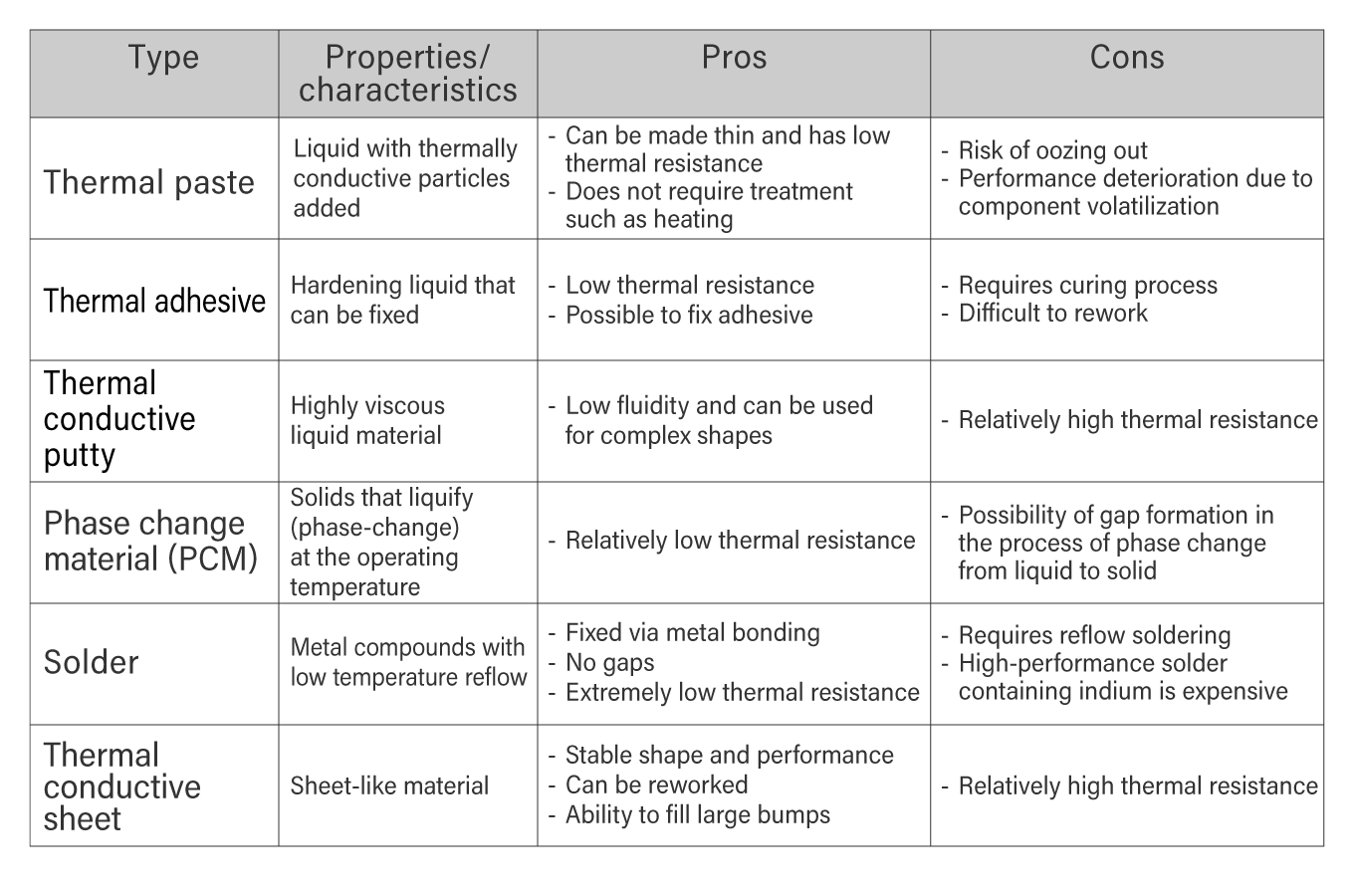

There are various types of TIMs (thermal interface materials) that help dissipate heat from heat sources such as ICs (integrated circuits). Dexerials manufactures thermal conductive sheets, a type of TIM gap pad. Other common types include paste, thermally conductive adhesives, putty, Phase Change Material (PCM), and solder. Each type has its own advantages and disadvantages, which are described below.

Thermal paste

Thermally conductive paste is a viscous liquid material made by adding thermally conductive particles, such as metallic powder, to a resin, such as silicone. It is also called liquid TIM. There is a wide range of thermal paste products that vary in price depending on their thermal conductivity. It is often used to dissipate heat in ICs such as CPUs (central processing units) because it does not require curing (heat treatment).

However, thermal paste has several reliability issues when used for a prolonged period. One of the problems is a phenomenon known as “pump-out”. In electronic devices, the paste fills the space between the heat source (e.g. IC) and the heat sink. But, due to the different thermal expansion characteristics between the heat source and the heat sink, the thermal paste is gradually pushed outward. In addition, with long-term use, the volatile components of the resin are often released, causing it to harden and deteriorate into a powdery state. In both cases, it loses its ability to fill the gaps between the substrates and thus cannot maintain proper heat transfer over long-term use.

Thermally conductive adhesive

In some cases, high thermal conductivity adhesives are used as TIMs. This method kills two birds with one stone by bonding (assembling) components and simultaneously improving heat dissipation at the same time. However, due to the nature of the adhesives, it is usually not possible to replace parts such as the IC or heat sink. In addition, bonding requires curing the adhesive in an oven, which adds equipment and operating costs.

Thermally conductive putty

A material similar to thermal paste is thermally conductive putty. It is more viscous than paste and can be applied in a lifted shape, making it an easy material to work with. There are two types, one that hardens and another that does not harden during the curing process. The challenge is that it tends to have a lower thermal conductivity than other TIMs, making it difficult to simultaneously meet rework requirements), high reliability (no dripping), and thermal conductivity.

Phase Change Material (PCM)

A PCM (phase change material) becomes solid or liquid depending on the temperature. PCMs are mainly composed of thermoplastic resin and are designed to soften at IC operating temperature range of 60-80°C and solidify at room temperature. The PCM softens when the IC is operating to ensure strong adhesion with the heat sink, thereby increasing the efficiency of heat dissipation. However, due to the characteristics of this type of material, it solidifies ⇔ liquefies repeatedly, which creates gaps during solidification and may reduce the adhesive area between the IC and the heat sink. Another disadvantage is that at room temperature, it solidifies and adheres to ICs and other components, making component rework more difficult.

Solder

Metal solder that melts at relatively low temperatures can also act as a TIM. When solder is placed between the heat source (such as an IC) and the heat sink, the extremely high thermal conductivity of the metal greatly increases the amount of heat transferred. Metals used for this purpose include Au-Sn (gold-tin) and In (indium), both of which are expensive and add to the cost of component assembly due to the addtional reflow mounting process. Another drawback is that soldering makes component replacement impossible.

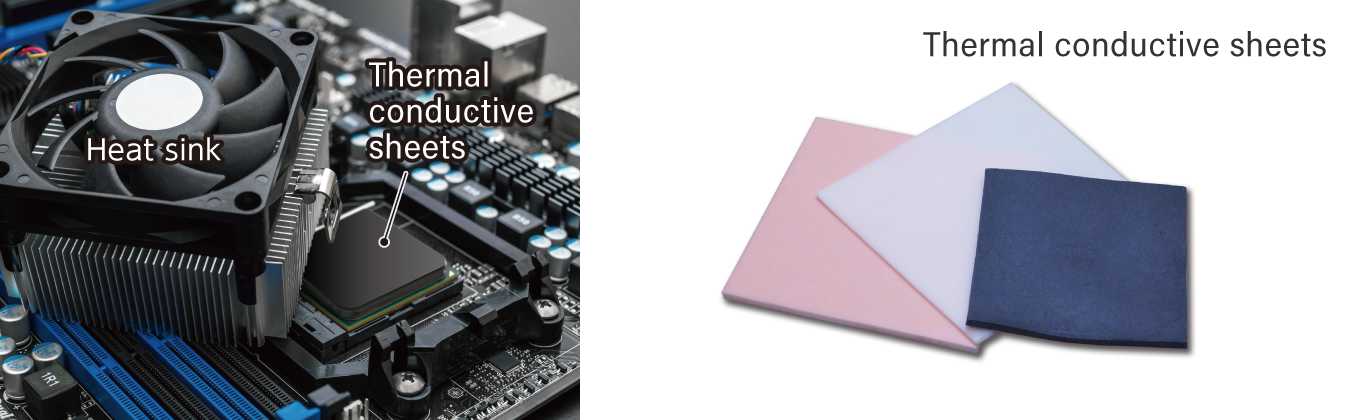

Thermal conductive sheets

Thermal conductive sheets are made of polymer material with thermally conductive fillers and are applied between the IC and the heat sink. They can be manufactured according to the shape of the product. The thickness can also be easily adjusted, which is important for TIMs. Unlike other TIMs mentioned above, they have stable performance and maintain its shape over a prolonged period of use. Another advantage not found in other TIMs is the ability to fill relatively large bumps, which is difficult to do with liquid materials. It is widely used as an easy-to-handle thermal material, with other advantages such as ease of replacement. On the other hand, it has lower thermal conductivity than metals, it is not as flexible as liquid materials, and its thickness cannot be changed on the spot.

Dexerials is dedicated to helping customers solve heat dissipation issues with thermal conductive sheets.

- SHARE

Back to top

Back to top  Contact us

Contact us