- Electronic Components

The SCP Story: How Dexerials’ secondary protection element evolved alongside electronic devices

Contents

The development of secondary protection element (SCP)

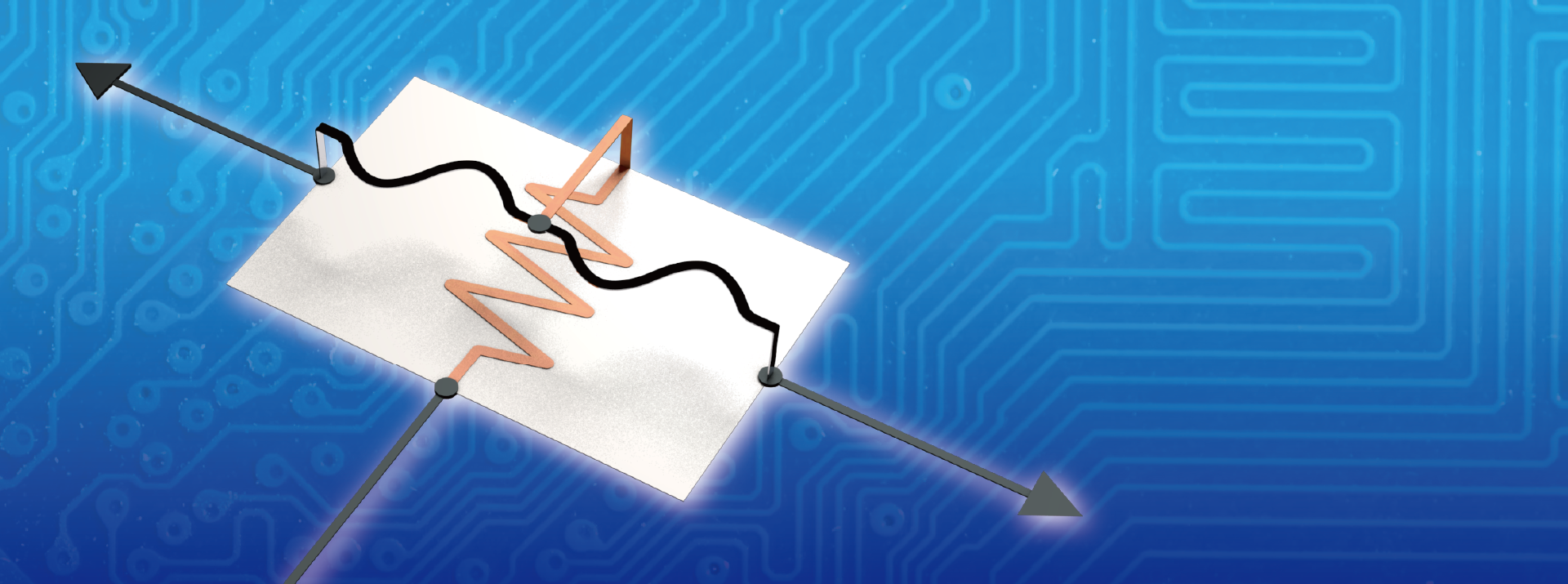

A self-control protector (SCP) is a secondary protection fuse that cuts off circuits when an overcharge or overcurrent occurs in the charge/discharge circuit of a lithium-ion battery. Developed exclusively by Dexerials, they have been installed in more than 2 billion electronic devices.

This article explains the background and future of SCPs.

The development of SCP began in 1991. At that time, mass production of lithium-ion batteries had just begun, and PTC thermistors (Positive Temperature Coefficient) were used as the protection fuse for charge and discharge circuits. The PTC thermistor was patented by another company and was an expensive component. That is why our customers asked Dexerials to develop a product to replace it.

Fuses made by other companies had a system that would increase resistance and stop electricity from flowing when they reached high temperatures. However, once the temperature drops, the flow of electricity restarts. Since flammable materials are used in lithium-ion batteries, it is safer to disable a product that has experienced issues. Therefore, we decided to develop a fuse that completely shuts off the circuit in the event of overcharge or overcurrent, thereby enhancing the safety of lithium-ion batteries.

How Dexeirals’ techninologies were used to develop SCPs?

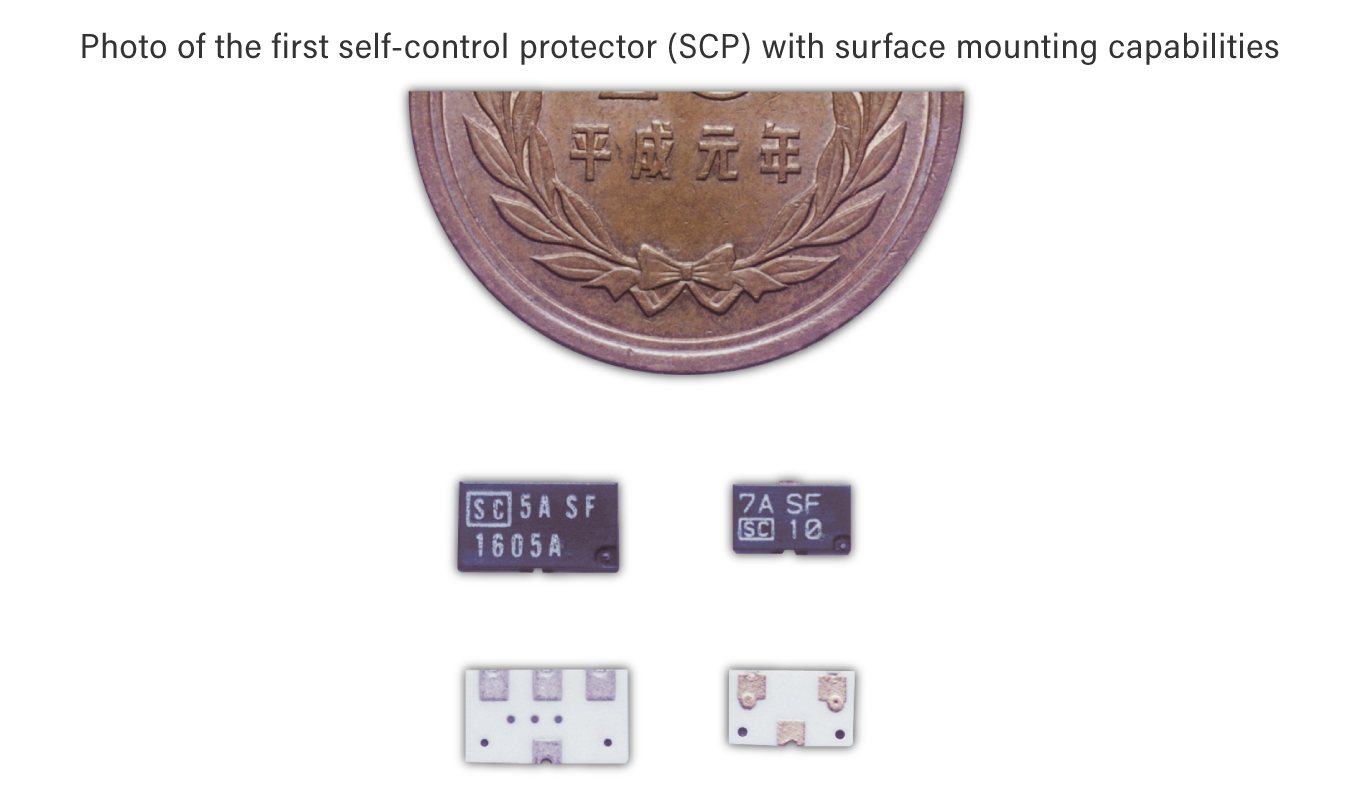

There were a lot of trials and errors after that. The first product that we developed was not a surface mount component like today’s products, but a flexible printed circuit board (FPC), on which a heating material was printed with press-connected fuses. They were connected using the hand soldering method instead of the surface mounting method,because FPCs are soft and bendable, However, a year after a customer request, we were able to develop and launch a product that could be mounted with an automatic mounting machine like the one we have now.

From Laptops to Smartphones and Lead-Free secondary protection element (SCP)

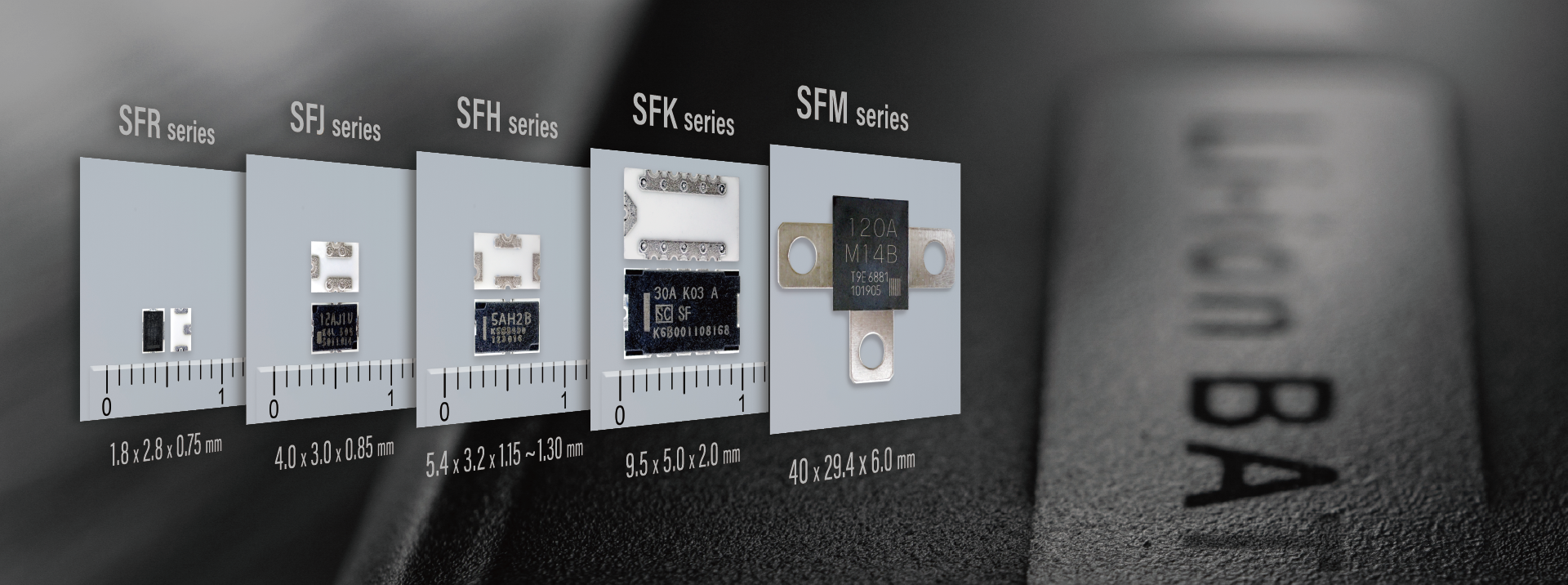

Improvement History after launched for laptop

We sold the first SCPs in 1994 and most of the devices equipped with SCPs were laptops. As companies continued to make laptops with improved performance, the power consumption of CPUs rose. People then began to ask for SCPs with lower resistance that could withstand higher electrical currents.

Initially, SCPs ensured front-to-back conduction by placing the circuit on the end of the ceramic substrate. However, this inevitably resulted in higher resistance due to the thin wiring on the shorter sides. Thus, we made a hole in the substrate and filled it with metal to increase the size of the cross-section and connect the front and back with the shortest route, thereby reducing resistance.

SCPs increasingly being used in smartphones

Especially with the recent rise of “quick charging” smartphones, we are developing new SCP products to meet this trend. Large currents are needed for a battery to charge quickly. SCPs are now required to have even lower resistance than conventional products.

Smartphones are also becoming thinner and more multifunctional, so the size of the SCP itself cannot change. So, we’ve had to meet the contradictory needs of both low-resistant and miniaturized SCPs, a rather difficult task.

Fuse element was a key

Conventional fuse elements are made of solder-based alloys. However, we were able to provide a solution by creating a fuse element with tin-based alloys plated and coated with silver. Silver conducts electricity easily, so it can carry about three times as much current as conventional fuse elements of the same size. In addition, the use of tin alloy enables the fuse to blow in the same temperature range as solder alloys.

Another major advantage of this technology is that it is lead-free, which was difficult to achieve with solder alloys. The EU’s RoHS Directive, which specifies hazardous substances in materials used in electronic equipment, does not regulate high-melting-point solders as of 2021. However, with the growing global awareness of environmental issues, there is a possibility that lead-based solders will be subject to regulations in the future. If this happens, we believe that the demand for our lead-free, low-resistance SCPs will increase dramatically.

The growing demand for secondary protection element (SCP) due to the pandemic

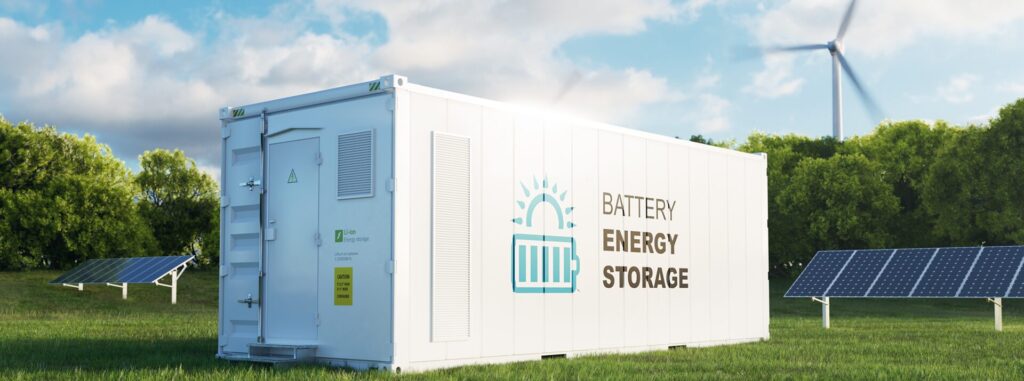

The pandemic had a tremendous impact on people’s work and daily lives. In response to the growing demand for SCPs, Dexerials is developing new technologies for the coming electric vehicle (EV) era.

The future of SCPs.

With remote work and online learning growing globally during the pandemic, the demand for laptops and tablets was also skyrocketing. Our first priority was to respond to the need. Also, as people spend more time at home, demand for electronics such as cleaning tools and power tools for DIY projects were grew. Such electronics devices are equipped with SCPs that can handle large capacities and large currents. Furthermore, we are developing SCPs that are compatible with EVs in anticipation to the shift from gasoline-powered vehicles to EVs.

Requirement of SCPs that are used in EVs

The biggest difference in lithium-ion battery packs used in EVs compared to electronic devices is that it generates voltages as high as 400V to 1,000V DC. At such high voltages, “arc discharge” occurs, in which electricity is discharged through the air and transmitted like lightning, even after the circuit has been interrupted by a fuse. For this reason, a different approach and structure from that of conventional SCPs are required.

The higher the voltage, the more difficult it is to interrupt a circuit. But without a reliable method of ensuring safe lithium-ion batteries, passengers and responders will be at risk in the event of an accident. There is no doubt that the need for EVs equipped with SCPs will increase globally. We are putting all of our efforts into improving and developing such products.

- SHARE

Back to top

Back to top  Contact us

Contact us