- Electronic Components

Secondary protection element technology for high current lithium-ion batteries

Contents

The increased current of lithium-ion batteries

Lithium-ion batteries are used to power devices such as laptops and smartphones. Advances in technology have led to higher current batteries devices. Recently, such batteries are also being used in a variety of applications including but not limited to cordless power tools and personal transportation vehicles, such as electric motorcycles and electric bicycles.

Dexerials manufactures fuse components, or SCPs (self-control protectors), which provide secondary protection for lithium-ion batteries. SCPs are now required for higher currents device applications. In this article, examples of how SCP works will be explained.

Connecting secondary protection element (SCPs) in parallel to handle higher currents

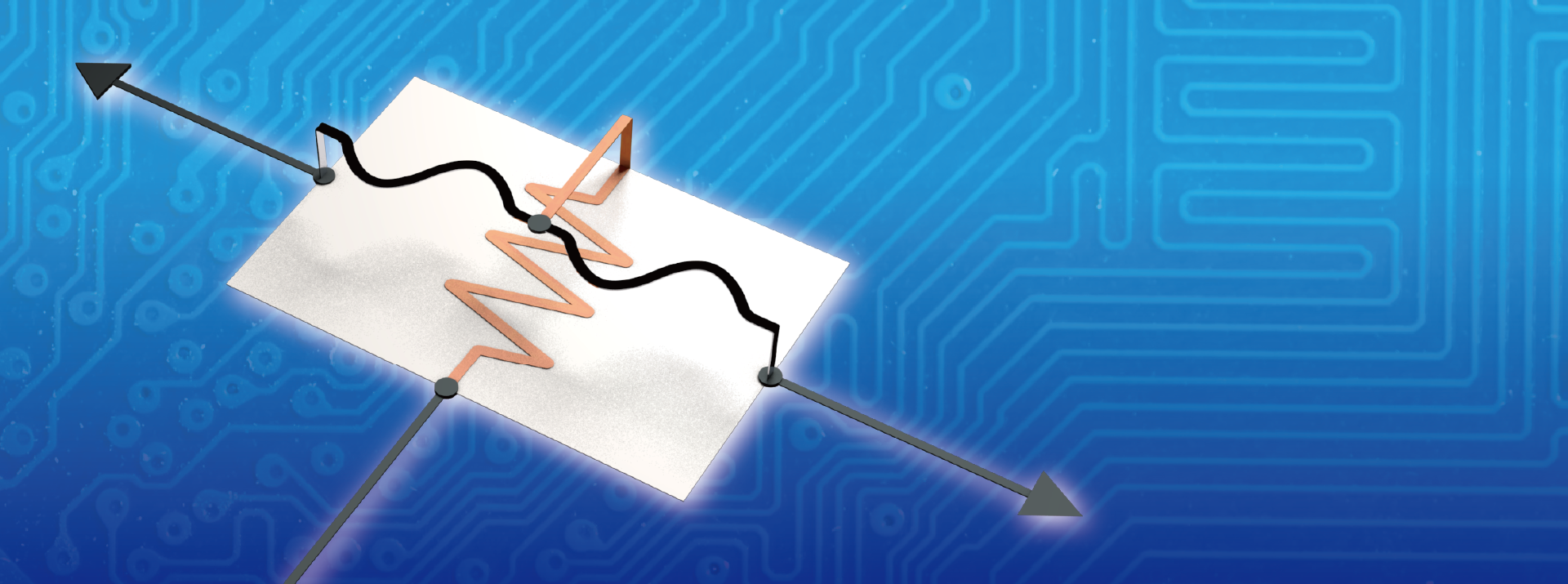

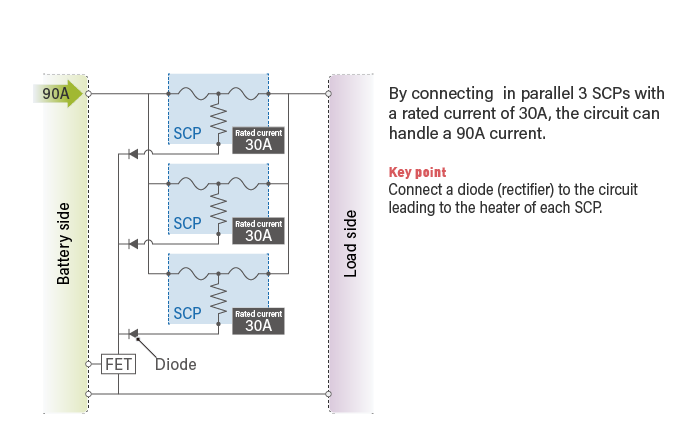

At Dexerials, single SCP is designed for the secondary protection in lithium-ion batteries. Having a simple structure and configuration are believed to be the best for optimum safety. However, for various reasons, there are cases where multiple SCPs can be connected to handle higher currents. Figure 1 is a diagram of such parallel circuit.

Figure 1 shows a circuit where three SCPs with a rated current 30A are connected in parallel to handle an overall current of 90A. The key point in this circuit diagram is that a diode (rectifier) is connected to the heater (resistor) that heats and blows the fuse element.

Why diodes are necessary

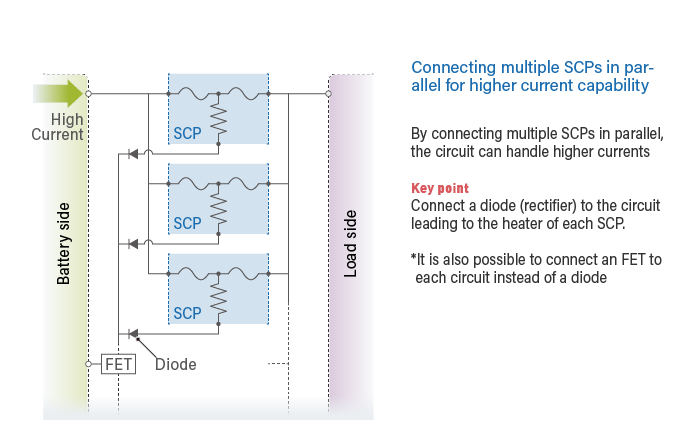

In the SCP parallel circuit introduced above, it is essential to include either a diode or a FET (field effect transistor), both of which serve the same function. The below Figure 2 shows the parallel circuit of an SCP before it was cut off by overcurrent protection. Any number of SCPs can be connected in parallel. That is why multiple SCPs can handle the flow of higher currents.

As will be shown later, in case when no diodes are connected to the parallel circuit, it may leave a path for the current to flow through even if the fuse blows. The basic premise of secondary SCP protection is to interrupt the circuit, blocking any path, so the current cannot flow through.

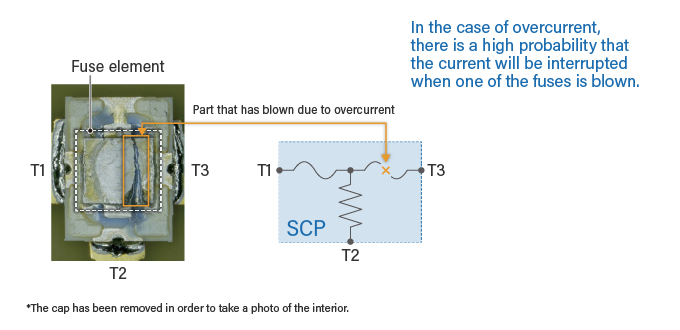

Figure 3 below shows a photograph of SCP fuse element after overcurrent protection. One part of the square fuse element has blown as if it had been cut vertically. As shown in the equivalent circuit (the circuit on the right side), there are two fuses in the SCP circuit, but only one of them has blown. When a circuit is broken due to overcurrent protection, it is likely that only one of the fuses will blow. To be precise, one of the fuses (e.g. the one with slightly higher electrical resistance) will blow first. As a result, the flow of electricity will stop at that stage, leaving the remaining side unblown.

Now let’s consider a case where there is no diode in parallel connection. Figure 4 shows three SCPs connected in parallel, each is fused for overcurrent protection. All three SCPs, A, B, and C, have either Fuse1 or Fuse2 blown. If the blown fuses are all on the same side (Fuse1 or Fuse 2), the entire circuit is broken, and the lithium-ion battery is protected. However, as shown in Figure 4, if all three blown fuses are not on the same side, some current will remain flowing in the circuit. This means that there is a risk that the integrity of the secondary protection cannot be ensured.

To solve this problem, a rectifier diode is added. By restricting the flow of electricity in one direction, the circuit will be interrupted no matter which fuse has blown. Since rectification is also possible with a FET (field effect transistor), which controls the current, it can be added as an alternative to a diode ( shown in Fig. 5).

Connect secondary protection element (SCPs) separately in charge and discharge systems

Fig. 6 shows an example of a circuit when SCPs are used in equipment that requires instantaneous high current, such as cordless power tools and electric motorcycles. The discharging and charging circuit are separate, and the SCP is used only in the charging circuit.

Generally, low rated current of about 3 to 10A are used for charging, even in power tools. In contrast, it is not uncommon to have a high current rating of 100A or more when a large amount of power is required, such as when an electric motorcycle starts going up a hill. If the charging and discharging circuits were identical, the high current during the discharge could cause the SCP to break. For this reason, when using SCPs for transportation and power tool battery applications, the circuit should be separated into discharge and charge. It should also only be used in a charging circuit designed for overvoltage protection.

Both the capacity and the current of lithium-ion batteries are increasing as its applications expand. For the safety of large equipment using lithium-ion batteries, Dexerials will continue to strive for further improvement of SCPs.

- SHARE

Back to top

Back to top  Contact us

Contact us