- Electronic Components

Heat Dissipation in Electronic Devices: Issues and Solutions

Contents

- 1 What to consider when designing heat dissipation systems in electronic devices

- 2 Differences between LED bulbs and incandescent light bulbs

- 3 How incandescent light bulbs emit light

- 4 The principles of light emission and heat dissipation of LED bulbs

- 5 Heat dissipation measures reduce costs of supercomputers and data centers

What to consider when designing heat dissipation systems in electronic devices

Heat dissipation is an important aspect in the design of electronic devices such as smartphones, laptops, and tablets. As the performance of electronic devices improved over the recent years, the degree of difficulty in heat dissipation measures increases as well. The below three main reasons will explain the challenges.

1. Low operating temperature

Automotive engines, which burn gasoline, can reach temperatures of several hundred degrees Celsius (depending on the part). But high temperatures do not cause them to fail or stop working. However, the silicon-based semiconductors used in central processing units (CPUs) of electronic devices are sensitive to heat, and their operation as electronic circuits becomes unstable when temperatures reach ~120°C. Therefore, to ensure stable operation, it is necessary to maintain an operating temperature of up to 100°C. The low operating temperature makes heat dissipation design challenging and will be explained in detail later on, using the difference between incandescent and LED bulbs as an example.

2. Increased heat generation due to increased power consumption

CPUs and ICs (integrated circuits) in electronic devices issue operational ‘commands’ to motors and other devices, but they do not perform the ‘work’ such as rotating motors to move things. Therefore, almost all of the generated energy is converted into heat. As development of electronic devices advances, power consumption will continue to increase due to the large amount commands issued to electronic devices to search for information on a daily basis. In the past, it was said that a single motherboard of a rack-mount computer installed in a telecommunications base station would use as much power as a hot plate (1500W or more). Recently, devices consuming as much as 6500W are now emerging in the telecommunications industry. If left unchecked, temperatures can rise to over 250°C. These devices must also be kept to less than 100°C to maintain functionality.

3. High heat generation density

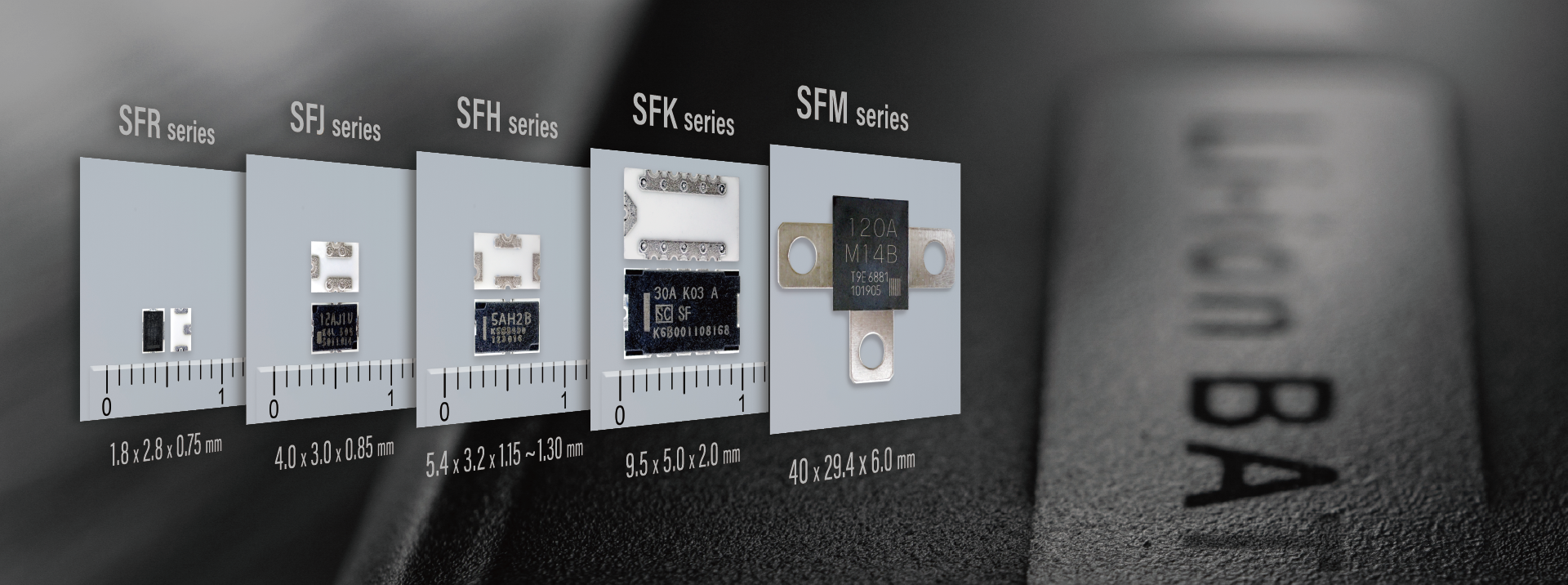

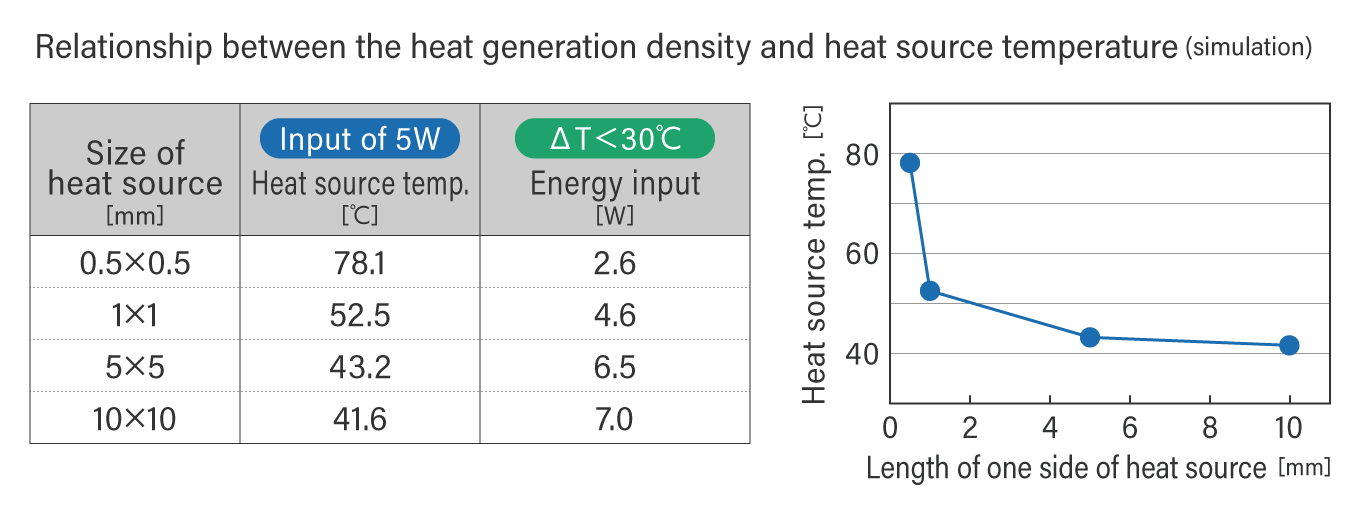

The same amount of energy generates more heat when it’s concentrated in a small area. With expansion of integrated semiconductors applications, the heat generation density increases, making heat dissipation more challenging.

Below is a table and graph showing that the temperature of a heat source can vary significantly depending on the heat generation density, even with the same heat generation value. It can be seen that with an input of 5W of energy, the smaller the size of the heat source, the higher the temperature.

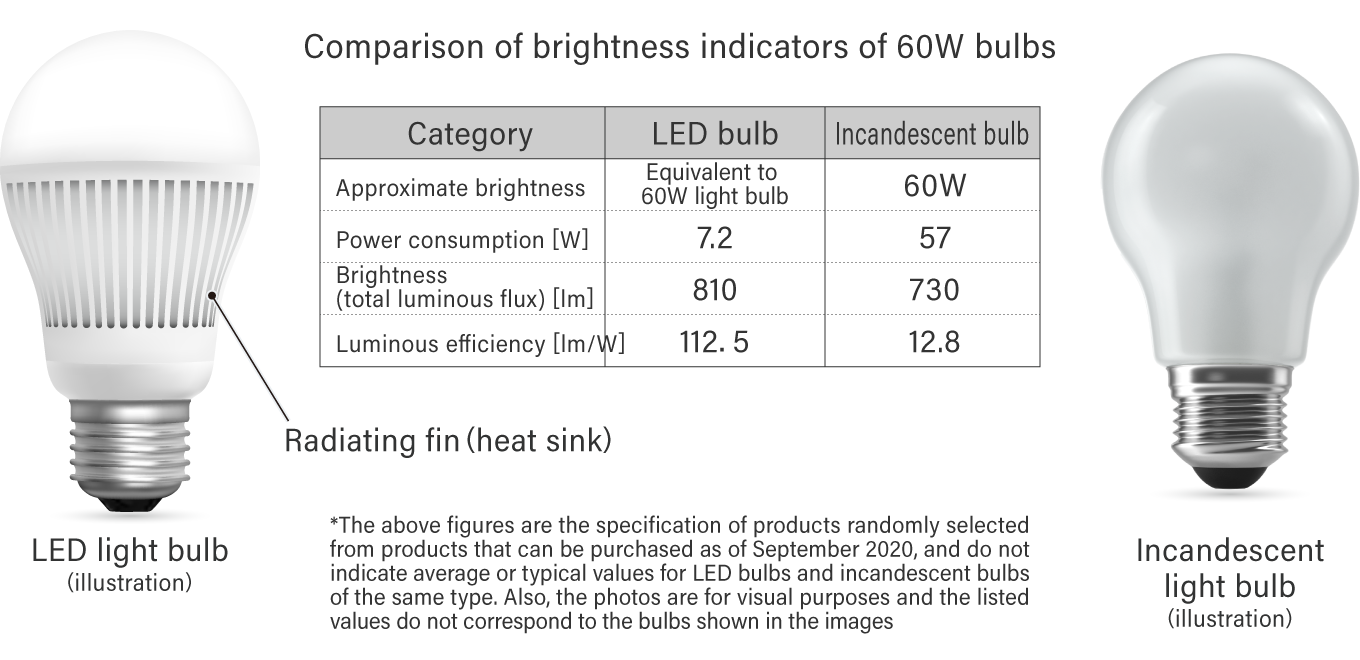

Differences between LED bulbs and incandescent light bulbs

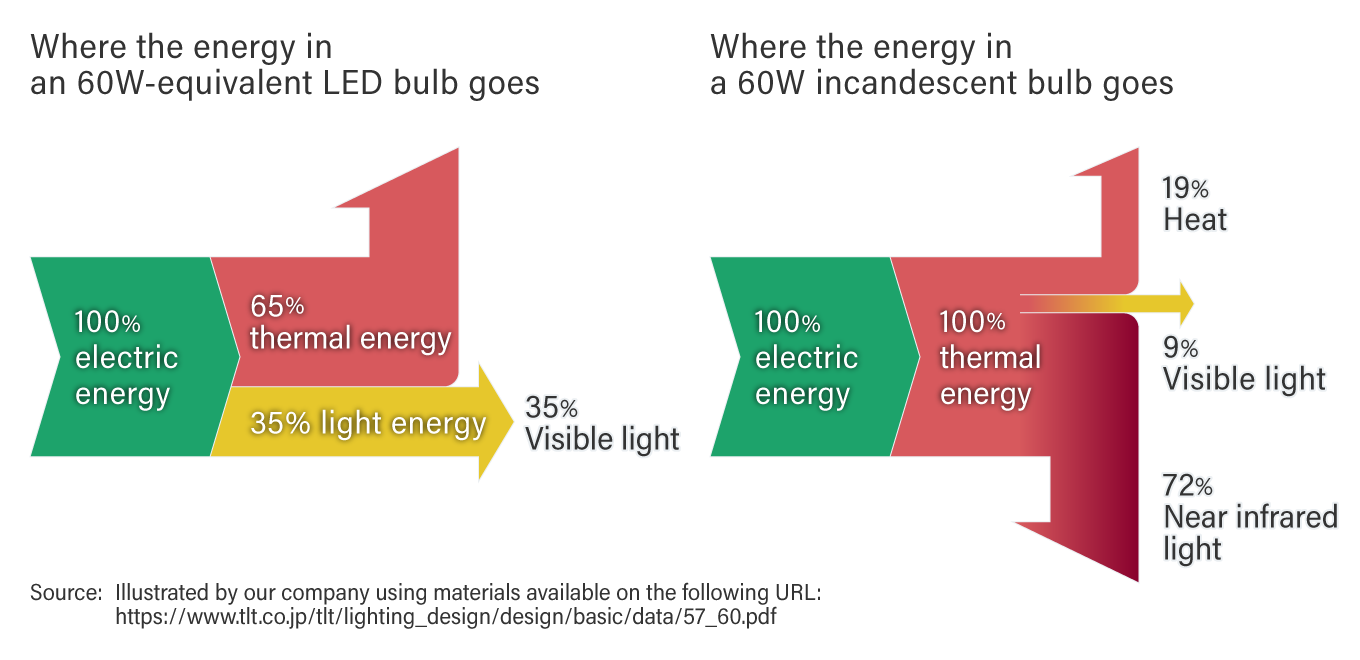

To exemplify the need for proper heat dissipation design in electronic devices, the differences between LED bulbs and incandescent light bulbs will be discussed. As shown in the table below, there is a several-fold difference in power consumption between the two. LED bulbs are brighter and use only 7.2W of electricity compared to 57W for incandescent light bulbs. This means that LEDs are far more efficient in converting energy into light.

Furthermore, as shown in the photo, LED bulbs have a fin (heat sink) under the bulb to dissipate heat, while incandescent light bulbs do not.

How incandescent light bulbs emit light

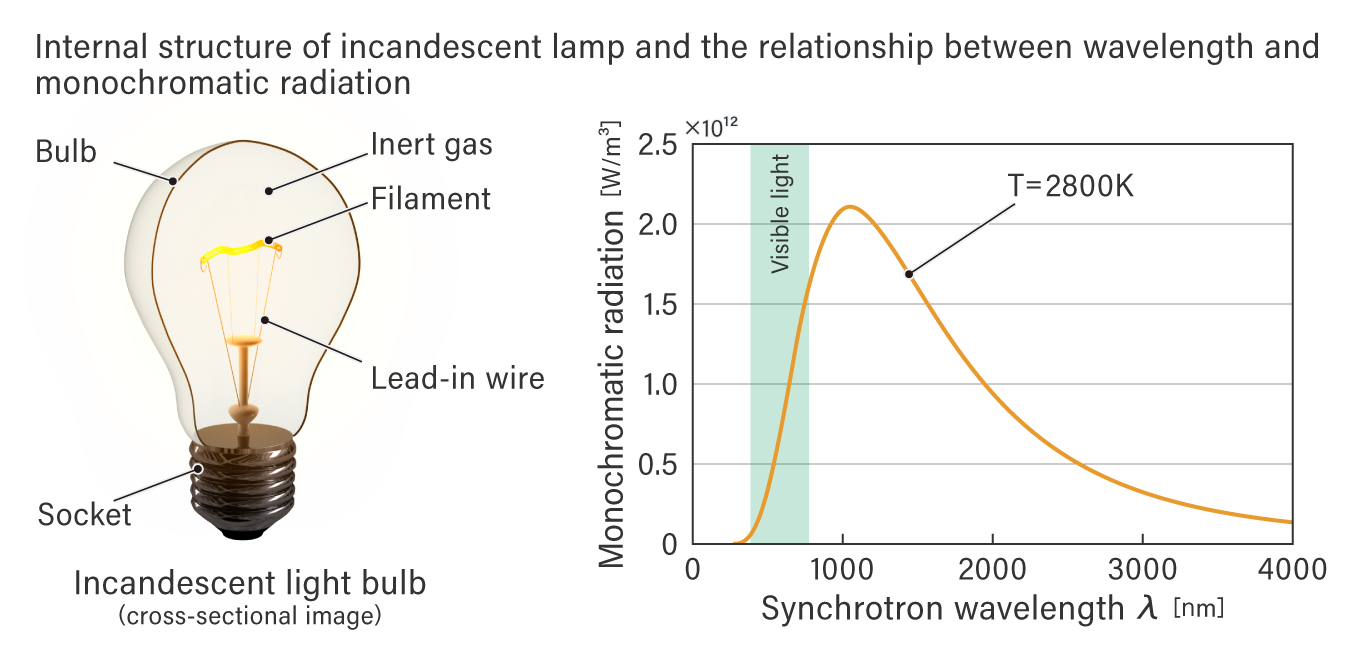

When electricity passes through a filament made of a metal called tungsten inside the incandescent light bulb (see photo below), most of the energy is converted into heat. Because of its extremely high temperature of about 2500°C, it generates thermal radiation, and some of the emitted electromagnetic waves are released outward in the form of visible light that can be seen by humans.

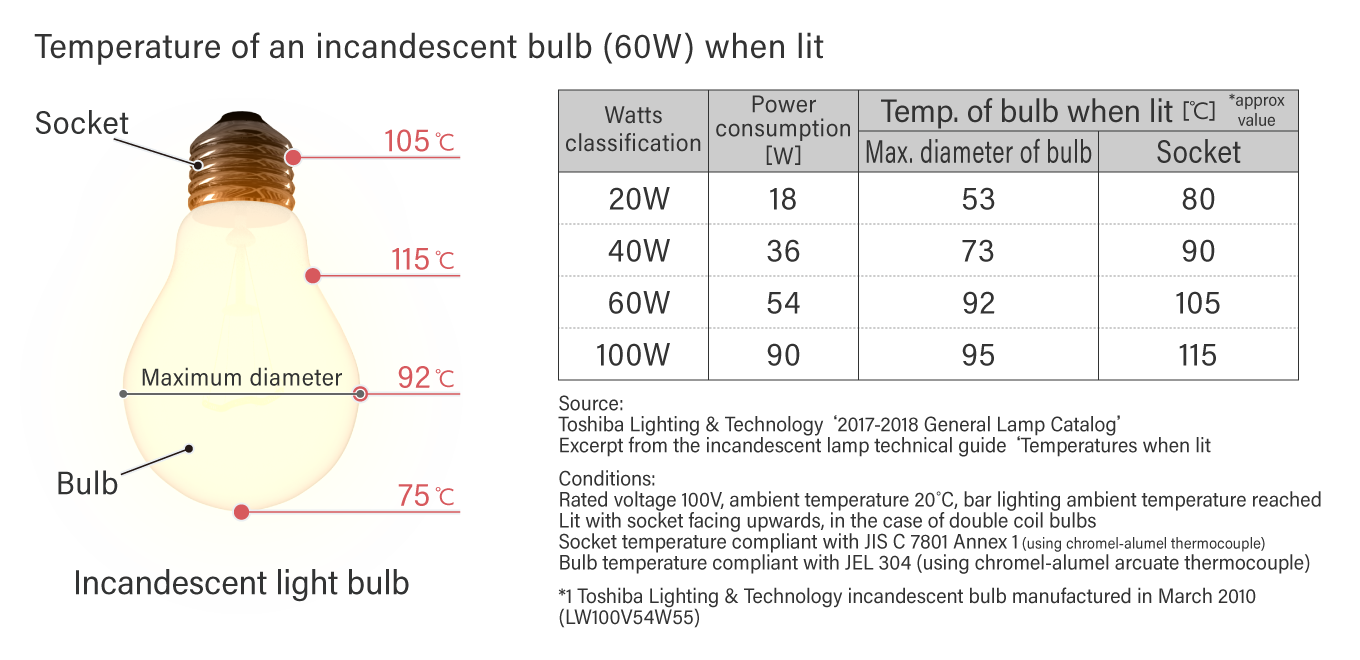

The incandescent light bulb is filled with an inert gas (a mixture of nitrogen and argon) to prevent the filament from burning (rapid oxidation). The heat from the filament, which can reach 2500°C, is reduced to less than 100°C by the time it is transferred to the bulb’s surface (the part with the largest diameter) because the inert gas suppresses any heat transfer. Also, since the heat source filament is very small, there is a limit to how much it can raise the temperature of the surrounding air, no matter how high the temperature becomes. Therefore, it does not require heat dissipation measures such as heat sinks.

The principles of light emission and heat dissipation of LED bulbs

Incandescent light bulbs use electrical resistance to emit light. On the other hand, LED bulbs use the ‘light-emitting diode’ principle, which directly converts electrical energy into light. When an electric current flows through a P-type semiconductor, which uses holes as charge carriers, and an N-type semiconductor, which uses free electrons as carriers, the electrons and holes move through the semiconductor and join at the surface. Part of the energy generated during this process is converted into light. This mechanism has a high luminous efficiency, where 35% of the energy input is converted into light (compared to about 9% for incandescent light bulbs), and the remaining 65% is emitted from the device as heat.

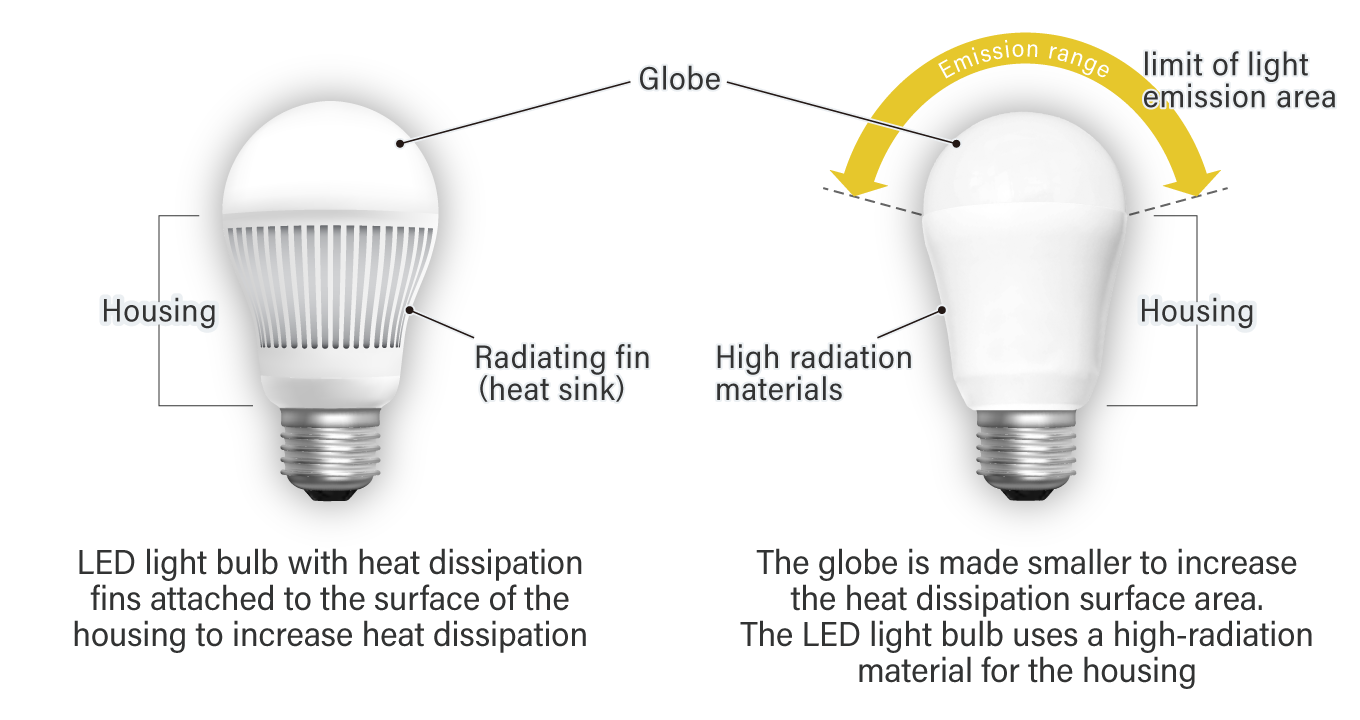

Unlike incandescent light bulbs, LED bulbs are semiconductor devices. Therefore, high temperature reduces performance and applied high temperature for a prolonged period of time can shortens the lifespan of the product. Conversely, if the temperature of the devices can be kept low, the bulbs will have high performance and a long life. Hence, heat sinks or other heat-dissipating systems must be installed to lower its temperature.

LED heat dissipation measures include increasing the heat dissipation surface area by creating indentation on the surface of the housing or reducing the size of the globe (where the bulb glows), and using high-radiation materials for the housing to increase heat dissipation efficiency.

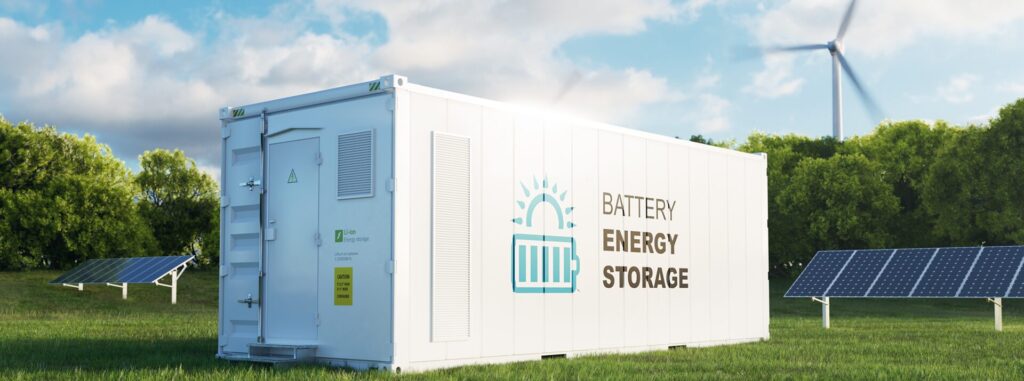

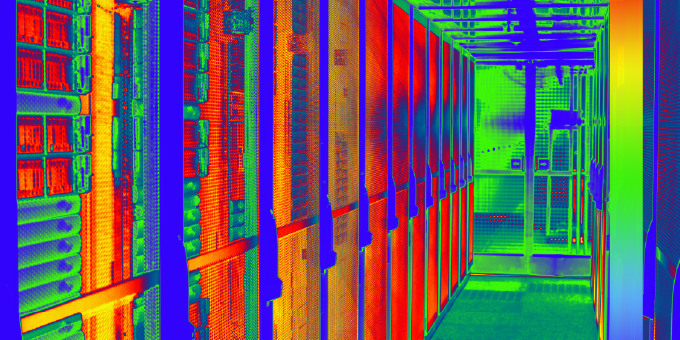

Heat dissipation measures reduce costs of supercomputers and data centers

In June 2020, RIKEN’s supercomputer Fugaku received the top global ranking in four categories measuring computing power. Supercomputers are the ultimate command center that process enormous amount of data at ultra-high speed and provide immediate instructions. Due to the large amount of consumed power which is mostly converted into heat, cooling methods which also consume power are needed. In order to solve the problems associated with these technological developments, advances not only in semiconductor technology but also in cooling technology and heat dissipation measures are indispensable. Data centers and telecommunication base stations also face similar challenges, just on a different scale.

5G, a high-speed, high-capacity, wireless communication technology is increasingly being used. In order to make such technology accessible, there is an urgent need to reduce system costs. Reducing the power required to cool and dissipate heat is considered as a cost-saving method. Dexerials has the materials and knowledge to provide a wide range of heat dissipation solutions for a variety of applications.

- SHARE

Back to top

Back to top  Contact us

Contact us