- 電子部品関連

鉛フリーを実現!リチウムイオン電池の環境負荷を下げる二次保護ニューズ新技術

目次

「鉛」を使用してきた二次保護ニューズのこれまで

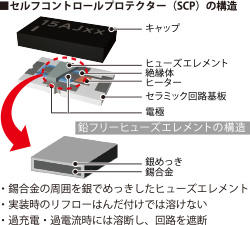

繰り返し充電して使えるリチウムイオン電池は、暴走による発火・発熱事故を防ぐために、一次・二次の保護回路が組み込まれています。デクセリアルズが開発したセルフコントロールプロテクター・SCPは、その二次保護を担うチップで、約30年前から現在まで、世界中のノートパソコンやスマートフォン、タブレットなどに搭載されてきました。

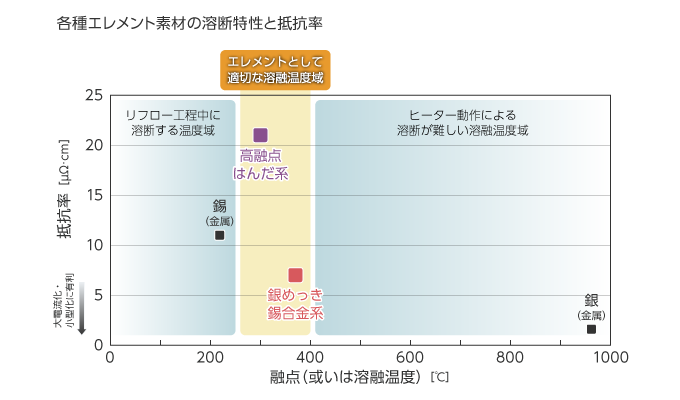

SCPの回路への実装は、効率に優れる「リフローはんだ付け」によって行われます。リフローはんだ付け工程では、内部のヒューズエレメントに230~260℃の熱がかかるため、ヒューズはその温度でも溶けない融点を持つ必要があります。一方で、リチウムイオンバッテリーが過電流・過充電に陥ったときには、すみやかにヒューズエレメントを溶断するため、260℃以上のなるべく低い温度で溶けるようにしなければならない。

この2つの要求を満たすのに都合の良かったのが、融点296℃の鉛含有合金でした。

世界の潮流へ。「鉛フリー」を実現する二次保護ニューズ

その課題とは、大きく分けて二つ。それぞれについて詳しく見ていきましょう。

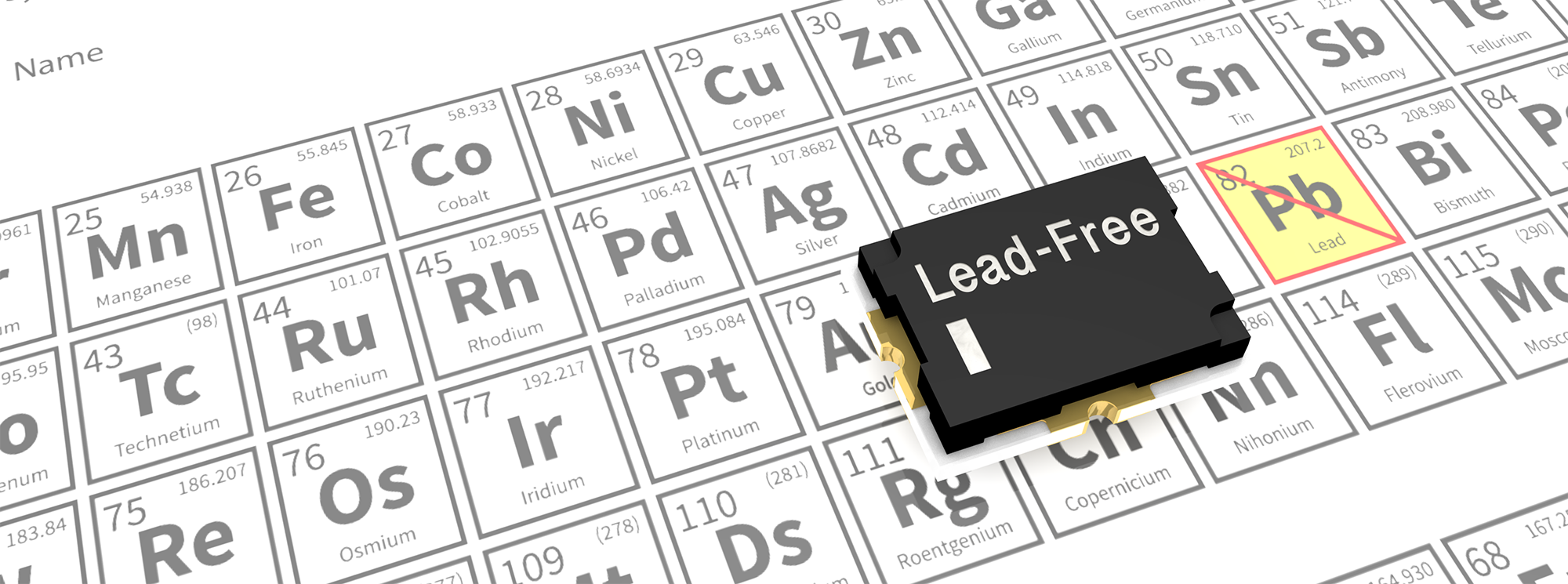

鉛は地球上に豊富に存在し、他の金属に比べて低い温度で溶融することから、安価で加工しやすいという特長があります。それゆえ鉛は古代からさまざまな用途で産業利用されてきましたが、一方で鉛には毒性があり、食べ物や水を通じて人体に蓄積すると、健康被害を及ぼす危険があることも知られてきました。そのため近年では、鉛による土壌や河川、海の汚染を防ぐため、多くの企業が「鉛の使用量削減」「鉛フリー」の取り組みを行っています。

欧州における有害物質の使用制限を定める「RoHS指令」では、鉛の含有率が重量で85%以上の高融点はんだ、電気電子部品に使用されるガラス・セラミック・鉛の複合材料などは適用除外となっています。そのため当社が開発した鉛含有ヒューズを使用するSCPも、現在にいたるまで規制対象とはなっていません。

しかし今後、鉛使用に対する規制はますます厳しくなっていくことが予想され、企業もより環境に配慮した部品や材料の調達に力を入れることは間違いありません。これが一つ目の課題。こうした時代背景に対応するため、私たちは「鉛フリー」ヒューズエレメントの開発に踏み切ることにしました。

電池の大電流化の足かせになった鉛ヒューズ

環境に対する悪影響とともに、鉛使用のヒューズにはもうひとつの大きな課題がありました。それは鉛が電気を流しにくい、すなわち「抵抗率が高い金属」であることです。抵抗率が高い金属ほど、電流が流れたときの発熱量は大きくなります。ヒューズという部品は、自身に電気が流れたとき発生する熱で溶断されることにより機能を発揮します。つまり鉛製のヒューズは発熱しやすいため、ちょっとの電流で切れてしまうのです。

電動バイクなどに使用されるリチウムイオン電池は大電流化が進んでおり、それに対応するSCPにも「大きな電流が流せる」ヒューズが必要となります。鉛よりも低い抵抗率の素材でヒューズが作れれば、「従来と同じ電流をより小さなサイズで流すこと」「従来と同じサイズでより大きな電流を流すこと」の両方が可能になります。すなわち、SCPの小型化・大電流化が実現できるのです。

錫と銀メッキの組み合わせで技術革新

以上に挙げた「鉛フリー化」と「低抵抗化」という2つの難しい課題を解決するために、私たちが編み出したのが「ヒューズの母材を融点217℃の錫合金で作り、それを融点962℃の銀でメッキで覆う」という手法でした。

この方法で作成されたヒューズは、リフローはんだ付け工程で内部の錫は溶けますが、銀メッキの被膜によって形状は保たれたままです。しかしリチウムイオン電池に過電流や過充電が発生し、ヒーターによってヒューズが400℃以上に温められ、一定の時間が経過すると内部の錫合金がどろどろに溶けて、表面の銀メッキと接している部分に「溶解現象」が発生します。液体の水に固体の岩塩を沈めると、ゆっくりと塩分が水の中に溶け出していきますが、それと同じように固体の金属(銀)も液体の金属(錫)と接することで、触れ合っている面が溶解していくのです。

この現象を利用したことにより、銀単独の融点よりも大幅に低い温度でヒューズエレメント全体を溶断することが可能となり、鉛を使わずに従来のヒューズと同等の二次保護機能を実現することができました。

低抵抗化により新たな製品の可能性を拓く

銀めっき被膜型ヒューズは、鉛フリーと同時に「低抵抗化」も達成しました。鉛の抵抗率は21μΩ・cmですが、錫は11μΩ・cmと低く、銀はさらに1.6μΩ・cmと極めて電気を通しやすい金属です。この錫と銀めっきを組み合わせたことで、ヒューズ全体の抵抗率は7μΩ・cmとなり、従来の約3倍の電流を同じサイズで流すことが可能になりました。

この技術により、デクセリアルズでは急速充電スマートフォンや、ドローンや工具などの大電流が発生する機器に対応するSCPの開発に成功し、特許を取得しました。鉛フリー・低抵抗化を達成した二次保護ヒューズ・SCPはすでに、市中で販売されている様々な製品で実用化されています。

これからも私たちは蓄積してきた技術と知見を活かし、より地球環境への負荷を低減するとともに、社会のニーズに対応する製品の開発を進めていきます。

関連記事

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら