- 電子部品関連

二次保護ヒューズ技術の基礎知識 リチウムイオンバッテリーの高電圧化への対応

目次

高電圧機器への搭載が加速するリチウムイオンバッテリー

ここ数年で、リチウムイオンバッテリーの用途が大きく広がっています。ノートパソコンやスマートフォン、タブレットPCなどに用いられるのは4V〜12V程度の電池パックですが、最近は一つの電池パックにセルを10本以上接続することで数十Vの高電圧を実現したリチウムイオンバッテリーが、電動工具や非常用電源、電動アシスト自転車や電動バイクにも用いられています。それにともない、万が一の過充電等のトラブルが起きたときに安全に回路を遮断する機能を持つ二次保護ヒューズ技術、セルフコントロールプロテクター(SCP)※にも、高電圧への対応が求められるようになりました。

※SCPは、1994年にデクセリアルズが販売を始めたリチウムイオンバッテリーの二次保護用ヒューズ素子で、これまでに多くのリチウムイオンバッテリーを用いた機器に搭載されています。

二次保護ヒューズ技術(SCP)を用いた高電圧機器向け保護回路の3事例

高電圧機器でSCPを用いた保護回路を組むには、いくつかの方法があります。ここから、デクセリアルズがお客さまに提案している代表的な3つの方法についてご説明します。

(二次保護ヒューズ技術であるセルフコントロールプロテクター(SCP)による低電圧機器向け保護回路については「リチウムイオンバッテリー向け二次保護回路用ヒューズ素子の仕組みとその歩み」で解説しています。あわせてご覧ください)

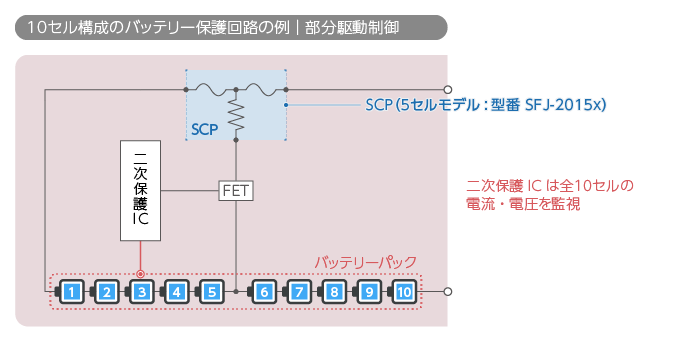

1.部分駆動制御

こちらは「部分駆動制御」と呼ばれる、10セルの電池のうち5セル分の回路をSCPに接続するという手法です。図の左側、電池パックの真ん中の5セル目から引き出された回路は、スイッチの役割をするFET(電界効果トランジスタ)につながれ、5セル分の電圧に対応した機能を持つSCPへと接続されます。規定を超えた電圧が保護ICにより検出された場合、FETがオンになり、SCPに内蔵されたヒーターが発熱し、ヒューズエレメントが溶断し充放電回路からリチウムイオンバッテリーが切り離される仕組みです。

この回路を見て「No.1〜No.5の5セル分の電池の不具合しか検出できないのではないか」と思われる方がいらっしゃるかもしれませんが、そうではありません。FETに接続された二次保護用ICが10セルすべての電池の電圧・電流を監視していますので、SCPに直接つながっていない残りの5個のセルに不具合が起きても回路は遮断されます。特別な部品を使わずに単純な回路で構成でき、比較的低コストで高電圧機器に搭載されるリチウムイオンバッテリーの二次保護を実現できるというメリットがあります。

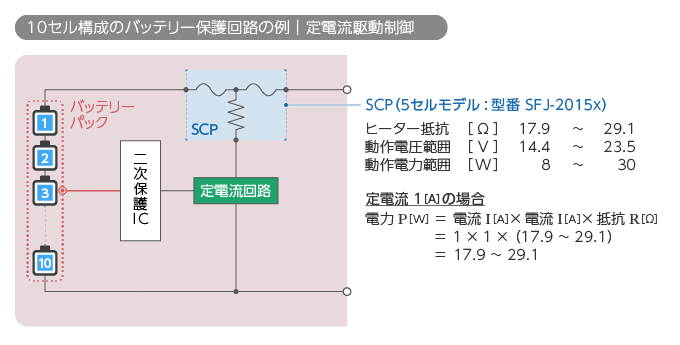

2.定電流駆動制御

SCPに内蔵されたヒーターには、規定の電圧を超えると保護ICの指令により電流が流れ発熱するように回路が組まれています。SCPは過充電検知時、このヒーターの熱を利用してヒューズエレメントを溶断、回路を遮断します。当然、電圧の変動にともないヒーターに流れる電流が変化すると発熱量が変動し、結果として溶断に要する時間が変化するなどヒューズとしての遮断特性に影響を与えます。そのため、ヒーターに流れる電流は変動が小さいことが理想となります。この方式では、二次保護用ICとSCPの間にある「定電流回路」が、ヒーターに流れる電流を一定にします。この図は、8〜30Wで切れるSCP(型番:SFJ-2015U)を組み込んだ場合、電流1Aで回路が遮断されることを示しています。安定した動作が可能ですが、定電流回路自身が複雑な回路であるためコスト面で不利と言われています。しかしながら、高い安定性を望むお客さまにはこういった方法もご提案しています。

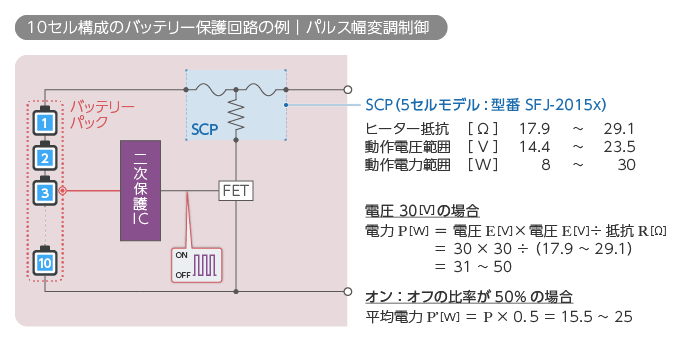

3.パルス幅変調制御

こちらはFETのオン・オフを、二次保護ICがパルス制御することで、トータルの電力を下げるという手法です。図では「2.定電流駆動制御」と同じ、8〜30Wで動作するSCP(型番:SFJ-2015x、動作電圧範囲:14.4-23.5V)を組み込んでいます。通常、動作範囲を超える電圧 30Vの回路には使用できず、仮に使用するとこのSCPはヒューズエレメントが溶断する前にヒーター回路が切れてしまいます。ここでパルス制御を導入すると、細かく電流のオン・オフを繰り返すことにより、トータルの電力を引き下げることができます。仮にオンとオフの比率を50%とすると、電力は半分の15.5〜25Wに下がり、電圧30Vの回路でもこのSCPが利用できるようになります。

この方式は、FETのオン・オフによる電力の調整をICで確実に制御できることから信頼性が高く、数多くのお客さまに採用された実績があります。また、通常のSCPは素子ごとに5〜9Vや10.5〜19.6Vといったように正しく動作する電圧の範囲が決まっていますが、この方式でパルス制御することにより、規定の電圧を超えて「3〜20V」といったような広い範囲で動作させることが可能となります。

リチウムイオンバッテリーは今後もさらに高電圧化が進み、様々な用途での使用が拡がることが予想されます。そうしたトレンドに対し、その保護に関する広範な知見と独自の技術で、今後もお客様のあらゆるニーズに対応してまいります。

関連記事

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら