- Electronic Components

Secondary protection of Li-ion batteries: function and development

Contents

- 1 Secondary Protection Solutions for Lithium-Ion Batteries

- 2 What is a lithium-ion battery?

- 3 Comparing Lithium and Lithium-Ion

- 4 The difference between primary battery and secondary battery

- 5 What is a secondary lithium battery?

- 6 How They Work

- 7 A product with a long history

- 8 How Battery Protection Circuits Work

- 9 What is a Lithium-ion Battery Protection Circuit?

- 10 Condensation sensor technology

- 11 A new method leads to a breakthrough in circuit interruption

- 12 Growing demand for lithium-ion batteries and SCPs

Secondary Protection Solutions for Lithium-Ion Batteries

Lithium-ion batteries, introduced in 1991, quickly became the standard for mobile devices due to their high voltage and low self-discharge rate. To enhance their safety, the Self-Control Protector (SCP) was developed as a secondary protection element to prevent overcharge and overcurrent. Over the years, SCP has played a crucial role in the evolving safety measures for lithium-ion batteries. This article provides an overview of lithium-ion batteries and explores the role and development of the Self-Control Protector (SCP) in enhancing battery safety.

What is a lithium-ion battery?

A lithium-ion battery (Li-ion) is a rechargeable battery, now the standard for portable electronics. Unlike traditional batteries, lithium-ion batteries can be recharged by reversing the chemical reaction. This ability to recharge makes them ideal for devices that require repeated use, such as smartphones, laptops, and electric vehicles. The key components of a Li-ion battery include a cathode, an anode, an electrolyte, and a separator, all of which work together to store and release energy. These characteristics have promoted their widespread adoption across a wide range of industries.

Comparing Lithium and Lithium-Ion

While lithium batteries and lithium-ion batteries both use lithium as a key component, there are significant differences between them. Lithium batteries are generally primary (single-use) batteries, while lithium-ion batteries are rechargeable. Lithium batteries tend to have a higher energy density and longer shelf life but are limited in their applications due to their single-use nature. Lithium-ion batteries, on the other hand, can be recharged hundreds of times, making them more suitable for devices that require frequent power cycling.

The difference between primary battery and secondary battery

Primary batteries are single-use and must be disposed of once depleted. In contrast, secondary batteries can be recharged and used multiple times, making them more cost-effective and environmentally friendly in the long term. The primary advantage of secondary batteries lies in their reusability, which is particularly important for applications that require sustained power over time, such as in laptops, smartphones, and electric vehicles.

For more information on the reuse and recycling of lithium-ion batteries, please see this article. Towards a Sustainable Society: The Recycling and Reuse of Lithium-ion Batteries and Dexerials’ Protective Devices

What is a secondary lithium battery?

Secondary lithium batteries refer to rechargeable lithium-based batteries, such as lithium-ion (Li-ion) and lithium-polymer (LiPo) batteries. These batteries can be recharged and used repeatedly. Characterized by high energy density and long lifespan, secondary lithium batteries are utilized in a wide range of applications, from consumer electronics to electric vehicles.

How They Work

Lithium-ion batteries function by moving lithium ions between the anode and cathode through an electrolyte. During discharge, lithium ions flow from the anode to the cathode, supplying energy to the connected device. When charging, an external power source returns the lithium ions to the anode, storing energy for later use. This reversible chemical process allows the battery to be recharged multiple times. As this advanced technology evolved, further efforts were made to enhance safety measures.

A product with a long history

Overcharging can lead to fire or explosion hazards because the electrolytes in Li-ion batteries contain flammable organic solvents. For this reason, the cells and charge/discharge circuits of lithium-ion batteries currently on the market are always equipped with a control function called “primary protection” to prevent problems that could lead to accidents, such as overcurrent or overcharge.

However, even the very best electronic circuits can fail in rare cases. In the early 1990s, Sony Chemicals (now Dexerials Corporation) was tasked with developing a secondary protection component for cases where primary protection in lithium-ion batteries failed.

How Battery Protection Circuits Work

Battery protection circuits are crucial components that safeguard lithium-ion batteries from potential hazards like overcharging, over-discharging, and short circuits. These circuits monitor the voltage and temperature of the battery, ensuring that it operates within safe limits. If any parameter exceeds its threshold, the protection circuit intervenes, disconnecting the battery from the load or charger to prevent damage.

What is a Lithium-ion Battery Protection Circuit?

A Lithium-ion battery protection circuit is specifically designed to protect lithium-ion cells. It typically includes a combination of electronic components such as transistors, diodes, and resistors that work together to control the current flow. The circuit also features a monitoring system that continuously checks the battery’s status and triggers protective actions if necessary. These circuits are vital in extending the lifespan of lithium-ion batteries and ensuring their safe operation in various applications.

Understanding these protective measures is crucial in ensuring the reliability of battery-powered devices across different applications, including those utilizing condensation sensor technology.

Condensation sensor technology

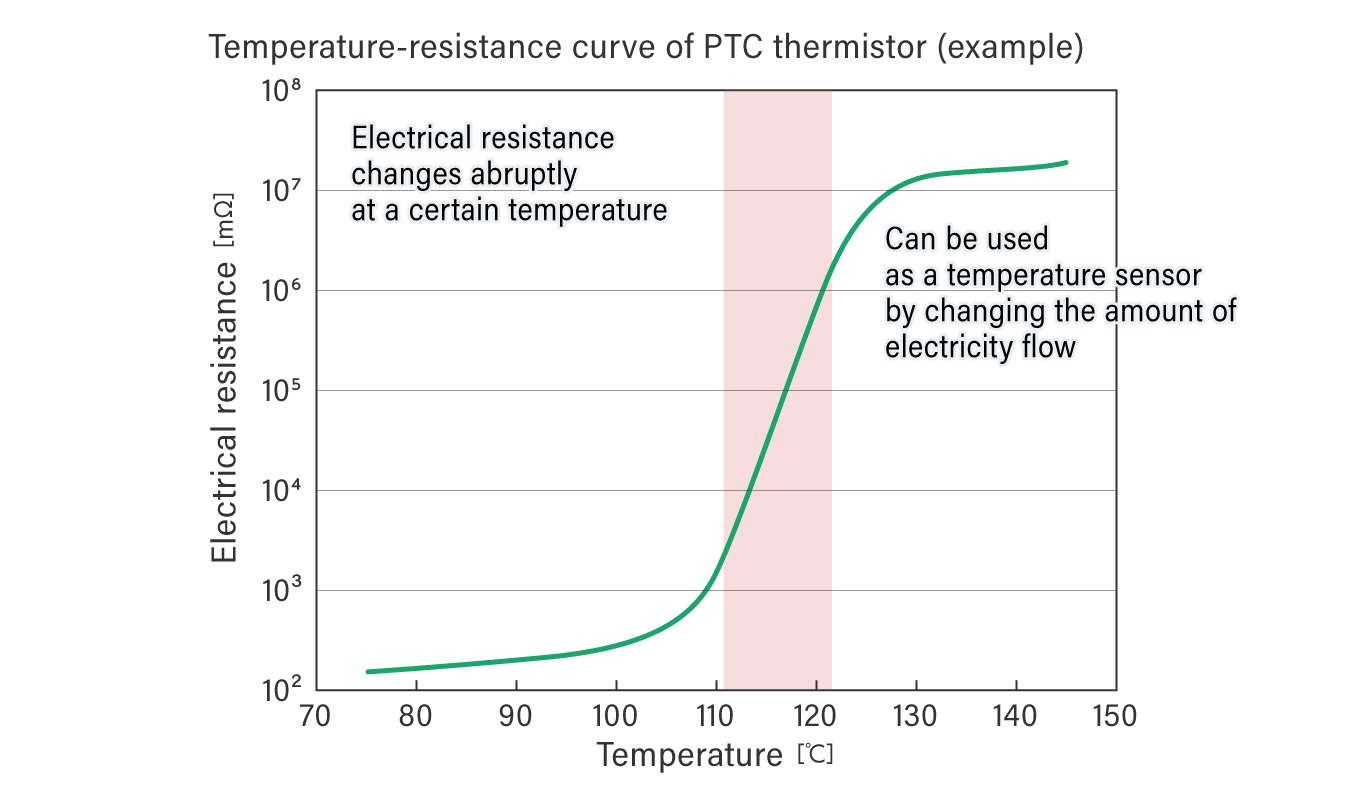

SCP development started with condensation sensors from video cameras. Initially, Sony Chemicals aimed to create a sensor similar to a PTC thermistor, using condensation sensor technology. However, this approach was not successful due to various challenges.

A new method leads to a breakthrough in circuit interruption

If a circuit is interrupted by conventional sensor technology, it can be used again once the temperature returns to its original state. However, it is dangerous to continue using lithium-ion battery that is already defective. Then, we shifted the concept to development of the product that completely shuts off the circuit once an overcharge or overcurrent occurs when the primary protection is not functioning.

After trials and errors, the solution was to incorporate a heater to blow the fuse. This method can handle both overcharge and overcurrent and can also physically interrupt the circuit.

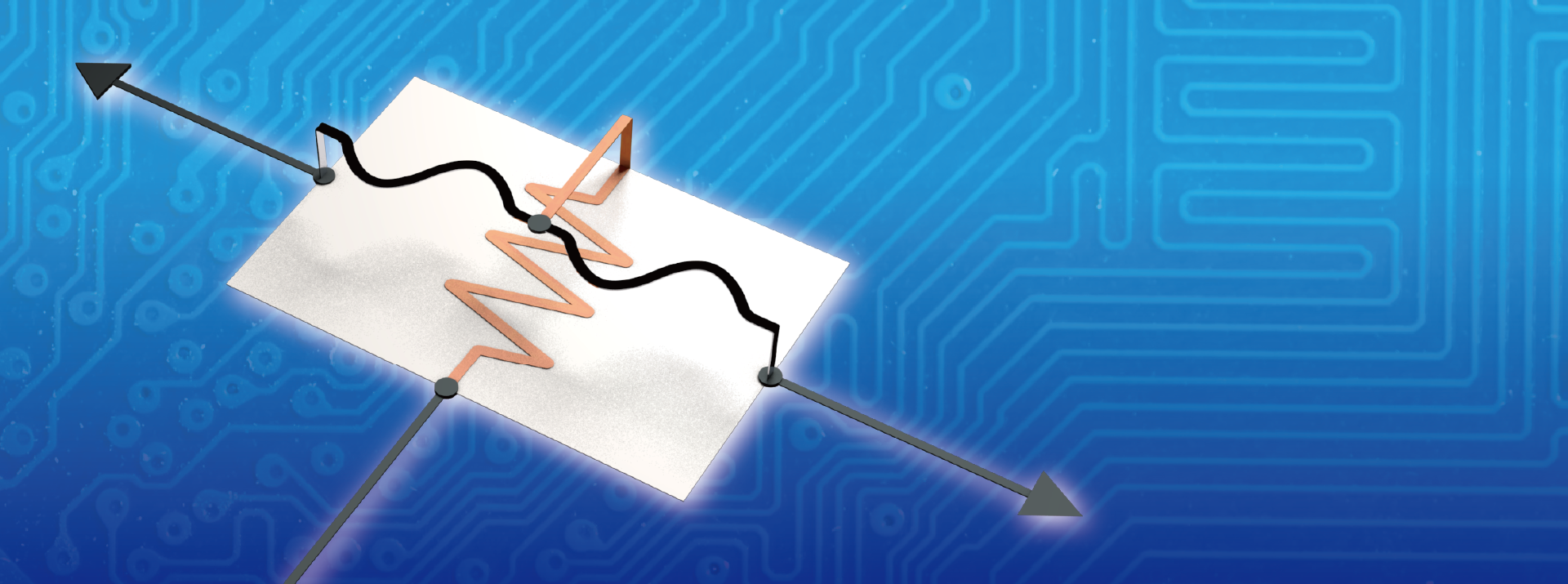

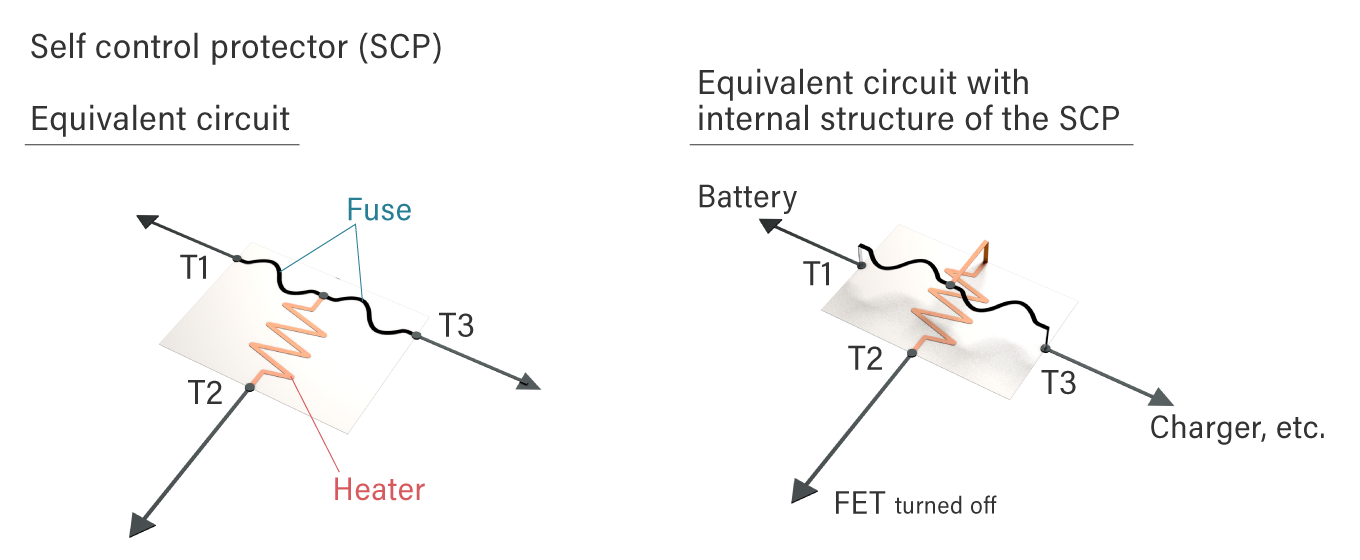

The electrical structure of SCPs is shown in the circuit diagrams below. On the left side is a generic circuit diagram, on the right side is a three-dimensional circuit diagram reflecting the internal structure of the SCP. The actual SCP has a structure where fuses are arranged in a three-dimensional intersection on top of a heater (resistor).

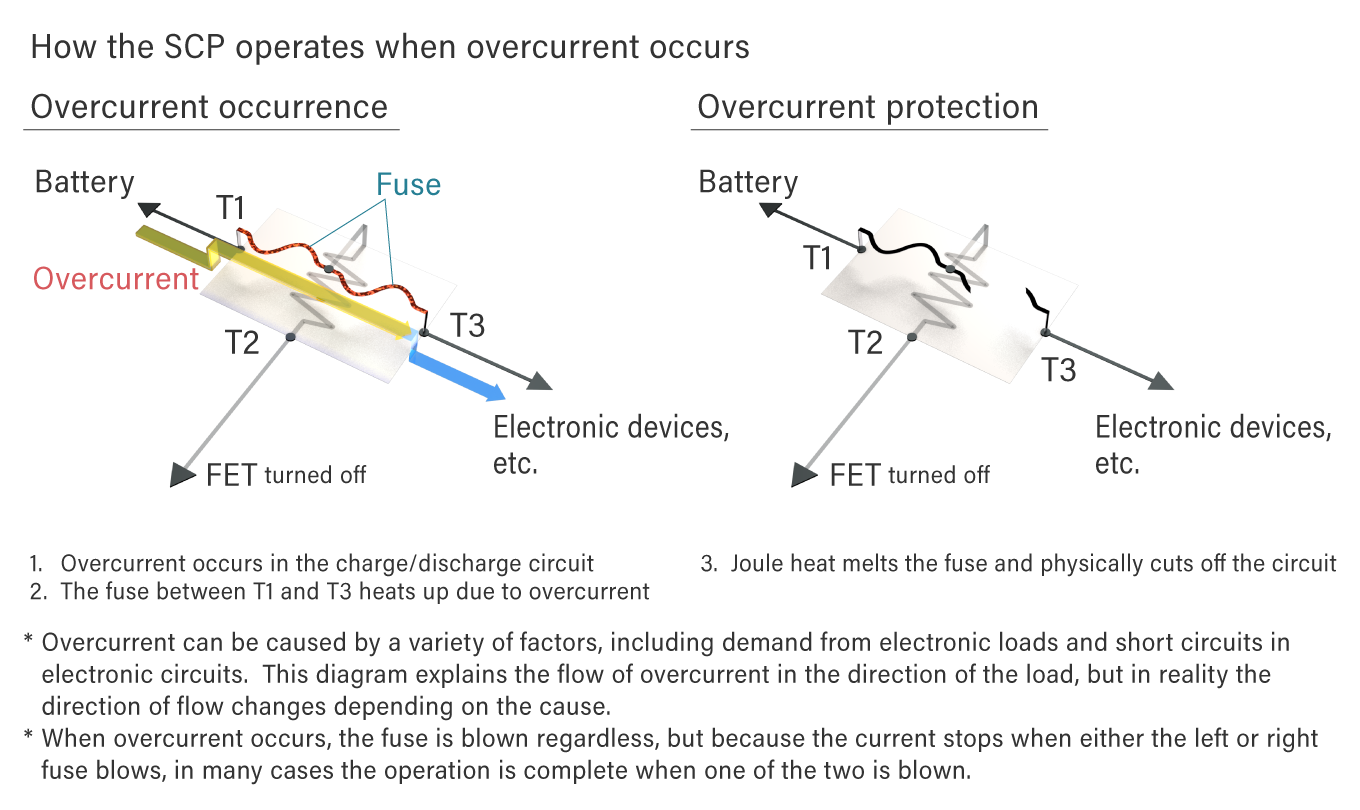

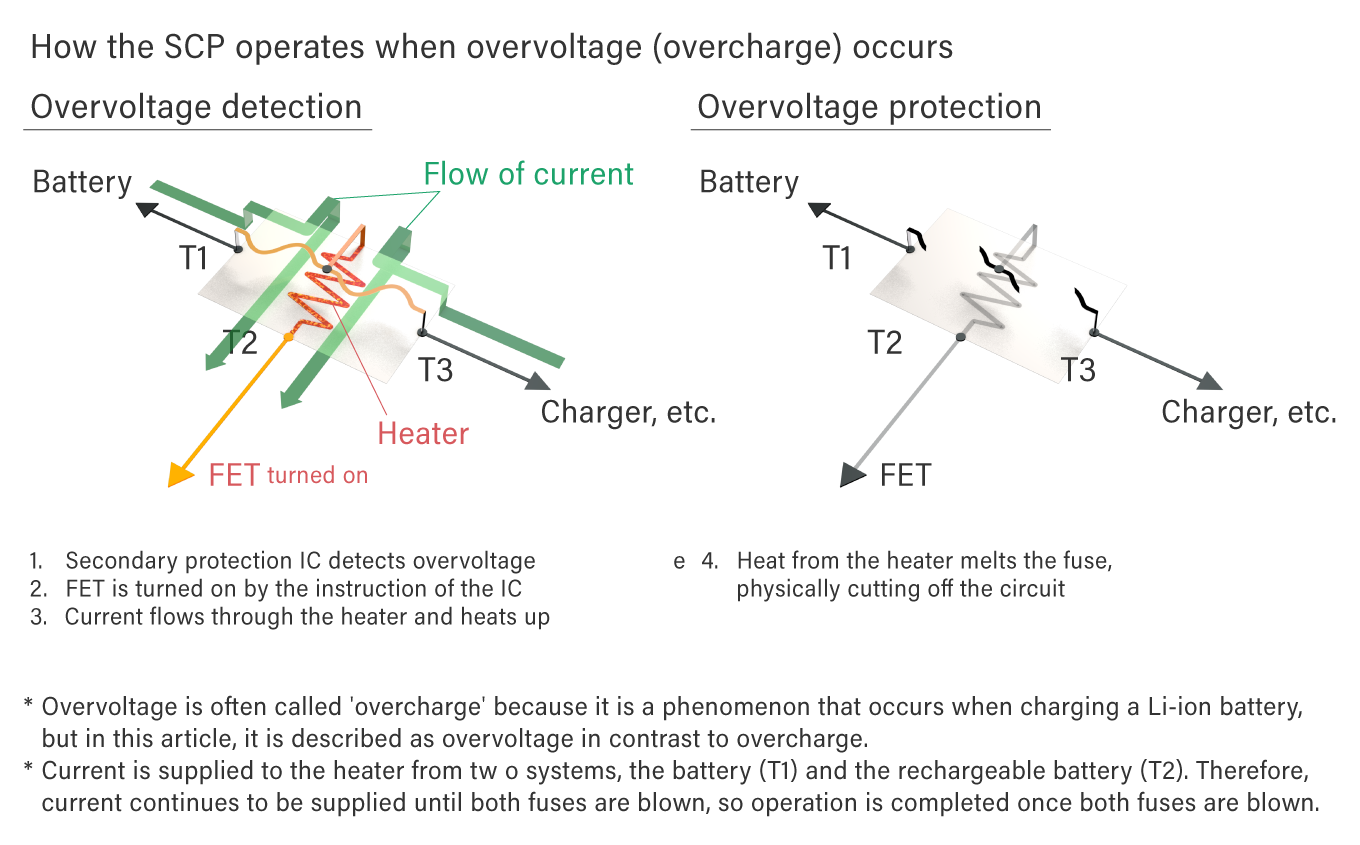

The diagrams below explain how SCPs operate.

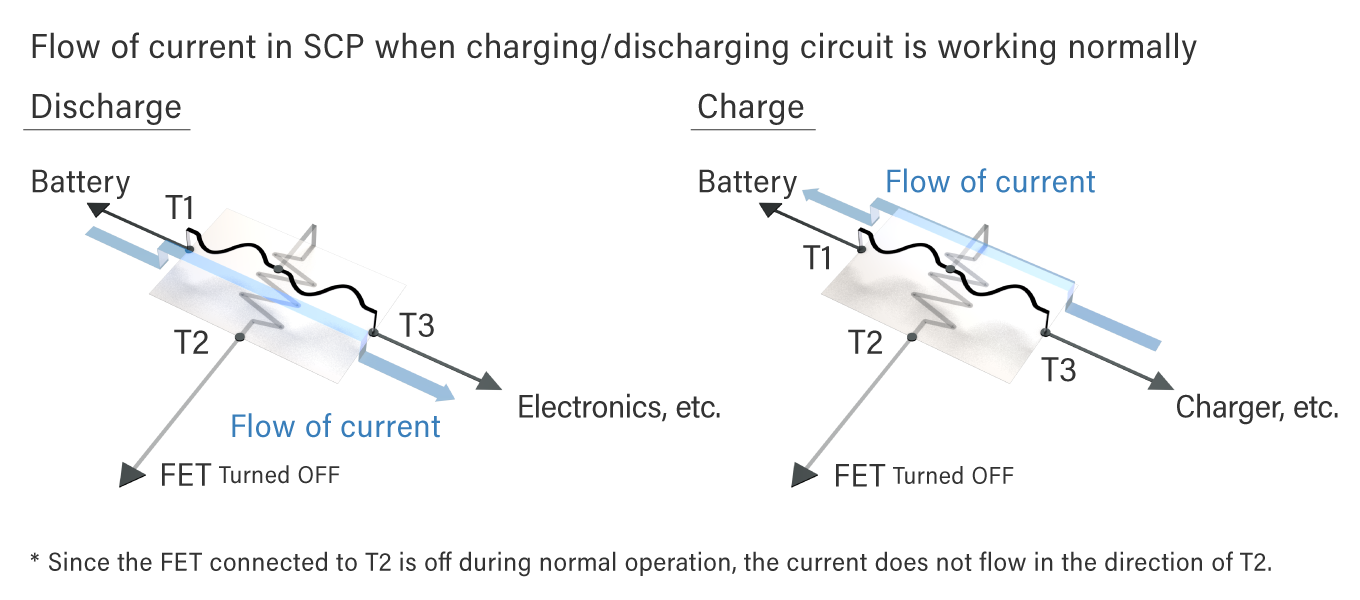

The current flow during normal discharge and charging is shown below.

When an overcurrent occurs, the fuse element is melted by Joule heat, interrupting the circuit.

When an overcharge occurs, the secondary protection IC detects the abnormality and turns on the FET, which operates the heater circuit. In this case, current flows to the heater from both T1 and T3 and generates heat. This heat is transferred to the fuse element, blows the fuse and interrupts the circuit. At the same time, the heater circuit gets disconnected, and the heat generation stops.

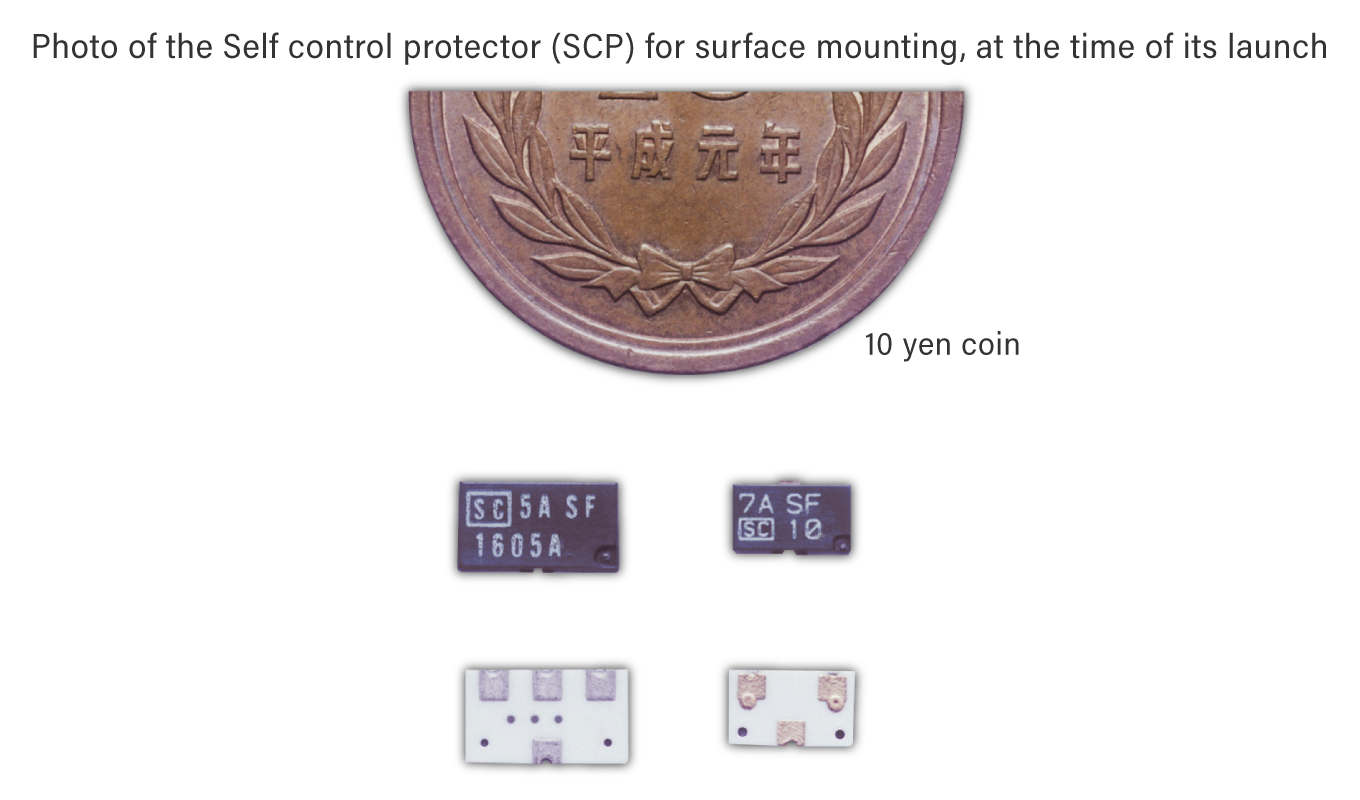

Initially, a flexible printed circuit board (FPC) was used as the base material for the circuit, but to accommodate surface mounting, the base material was changed to a ceramic substrate. Thus, we completed the prototype of SCP.

Growing demand for lithium-ion batteries and SCPs

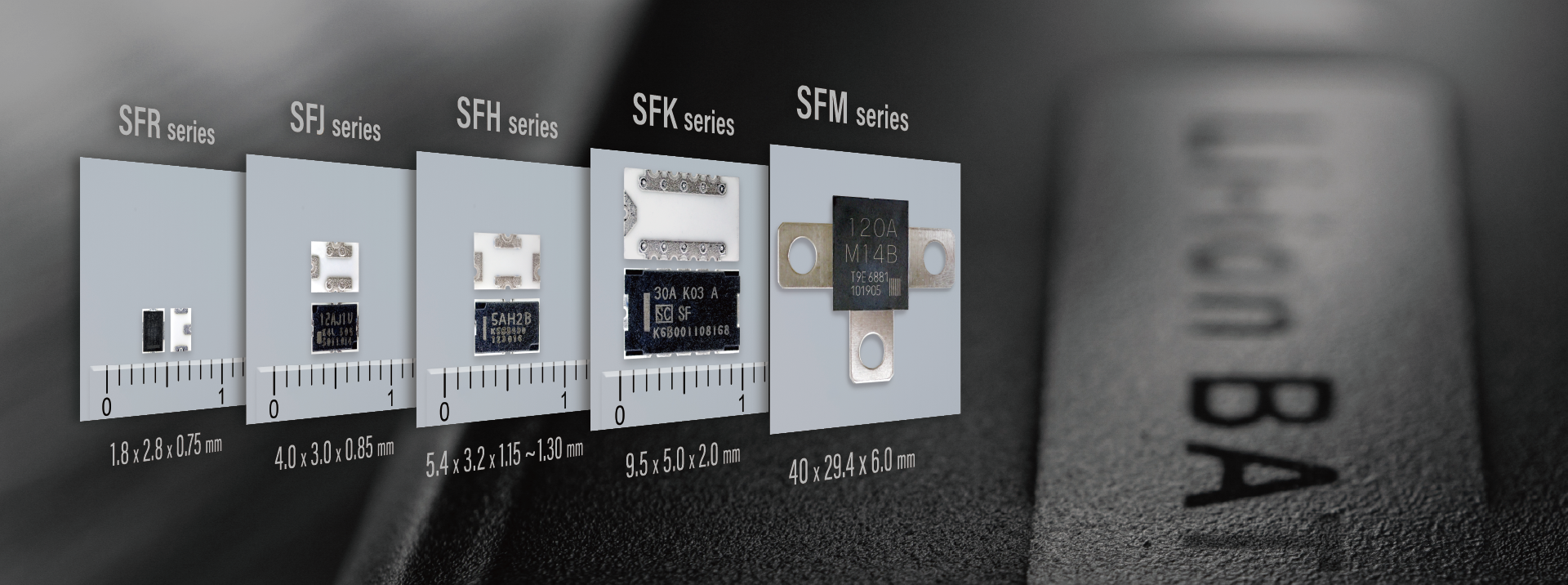

In 1994, we obtained a foundational patent for the laminated structure of the SCP’s heater and fuse. In the same year, a lithium-ion battery equipped with SCP in its secondary protection circuit was launched. The lithium-ion batteries with SCPs were quickly adopted by many computer manufacturers. Today, Dexerials’ SCPs are still used as fuses in the secondary protection circuits of many products, including laptops.

_EN_SCPラインアップ_EN-1.png)

As the lithium-ion battery market expanded, so did the demand for SCPs. Today, these batteries are used in laptops and large electrical products like cordless tools, industrial batteries, and electric vehicles. For smaller devices, it is used in laptops, tablets, quick-charging smartphones, and automated external defibrillators for medical devices. As the world is beginning to shift from gasoline engines to motors, SCPs will also be required to handle higher voltages in large devices.

Technology continues to change rapidly. Dexerials will continue developing products to meet a wide range of demands.

- SHARE

Back to top

Back to top  Contact us

Contact us