- 電子部品関連

リチウムイオンバッテリー向け二次保護回路:ヒューズ素子の機能と進化

目次

バッテリー安全性向上のための保護技術

リチウムイオンバッテリーが世界で初めて商品化されたのは1991年です。それまで二次電池(充電して繰り返し使える電池)のスタンダードだったニッケル水素バッテリーに比べて約3倍の電圧を持ち、放置している間の自己放電量も少ないリチウムイオンバッテリーは、モバイル電子機器のバッテリーに適していたため、世界中で急速に普及しました。この記事では、リチウムイオンバッテリーの基本概要と、安全性向上に貢献している「セルフコントロールプロテクター(SCP)」の役割およびその発展の歴史ついて解説します。

リチウムイオンバッテリーの概要

リチウムイオンバッテリーは、モバイル電子機器で広く使われている充電式電池の一種です。従来のニッケルカドミウム電池とは異なり、リチウムイオンバッテリーは化学反応を逆転させることで再充電が可能です。この再充電能力により、スマートフォン、ノートパソコン、電気自動車など、繰り返し使用されるデバイスに最適です。リチウムイオンバッテリーの主要な構成要素には、カソード、アノード、電解質、およびセパレータが含まれ、これらが連携してエネルギーを蓄え、放出します。リチウムイオンバッテリーはその高エネルギー密度と低自己放電率によって幅広い産業で普及しています。

リチウムバッテリーとリチウムイオンバッテリーの比較

リチウムバッテリーとリチウムイオンバッテリーは、いずれもリチウムを主要材料として使用しますが、両者には大きな違いがあります。リチウムバッテリーは一般に使い捨て(一次電池)であるのに対し、リチウムイオンバッテリーは充電式です。リチウムバッテリーはエネルギー密度が高く、保存期間も長い特徴があり、使い捨てである一方、リチウムイオンバッテリーは再充電・再利用が可能です。

一次電池と二次電池の違いについて

一次電池は、化学反応が完了するまで電力を供給し、その後は再充電できないため使い切ったら廃棄する必要があります。これに対して、二次電池は再充電が可能で、複数回使用することができるため、長期的にはより経済的で環境にも優しい選択肢です。二次電池の主な利点は、その再充電可能であることにあり、ノートパソコン、スマートフォン、電気自動車など、長期間にわたって電力供給が必要な用途において特に重要です。

リチウムイオンバッテリーのリユース・リサイクルに関する詳細はこちらの記事をご覧ください。持続可能な社会に向けたリチウムイオン電池のリサイクル&リユースとデクセリアルズの保護素子

リチウム二次電池の特徴

リチウム二次電池とは、リチウムイオンバッテリーやリチウムポリマーバッテリーなどの再充電可能なリチウムベースの電池を指します。これらの電池は、繰り返し充電して使用することができます。リチウムイオンバッテリーは、高エネルギー密度と長寿命が特徴で、消費者向け電子機器から電気自動車に至るまで、幅広い用途に対応しています。リチウムポリマーバッテリーは、リチウムイオンバッテリーの一種で、柔軟な形状にすることが可能なため、特定の用途に適しています。

リチウムイオンバッテリーの動作原理

リチウムイオンバッテリーは、アノードとカソードの間でリチウムイオンが電解質を通じて移動することで動作します。放電時には、リチウムイオンがアノードからカソードに移動し、接続されたデバイスにエネルギーを供給します。充電時には、外部の電源によってリチウムイオンがアノードに戻されることでエネルギーを蓄え、後で使用できるようにします。この可逆的な化学プロセスにより、電池は何度も充電され、再利用が可能です。リチウムイオンバッテリーの技術が進化する過程で、さらなる安全性を追求するための取り組みが行われました。

パイオニアメーカーからの依頼

リチウムイオンバッテリーは、そのエネルギー密度の高さから、誤使用時に発熱や発火の危険があります。そのため、過電流や過充電を防ぐ「一次保護」が必須です。しかし、一次保護が故障した場合に備え、1990年代初頭、当社の前身であるソニーケミカルは、二次保護機能の開発を依頼されました。

バッテリー保護回路の機能

バッテリー保護回路は、リチウムイオンバッテリーを過充電、過放電、短絡といった潜在的な危険から守るための重要な部品です。これらの回路はバッテリーの電圧や温度を監視し、バッテリーが安全な範囲内で動作することを保証します。いずれかのパラメータが許容値を超えると、保護回路が介入し、バッテリーを負荷や充電器から切り離して損傷を防ぎます。

リチウムイオンバッテリー保護回路の役割

リチウムイオンバッテリー保護回路は、特にリチウムイオンセルを保護するよう設計されています。通常、トランジスタ、ダイオード、抵抗器などの電子部品の組み合わせで構成され、これらが協力して電流の流れを制御します。また、バッテリーの状態を継続的に監視し、必要に応じて保護動作をトリガーするモニタリングシステムも備えています。これらの回路は、リチウムイオンバッテリーの寿命を延ばし、様々な用途で安全に動作させるために不可欠です。

これらの保護対策を理解することは、結露センサー技術を含む様々な用途において、バッテリー駆動デバイスの信頼性を確保する上で重要です。

結露検知センサー技術の応用がスタート

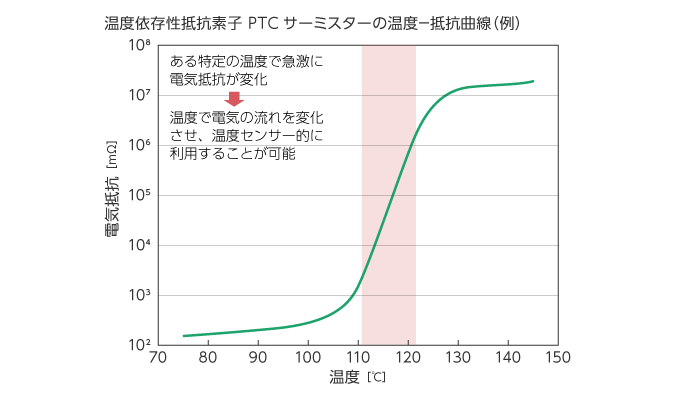

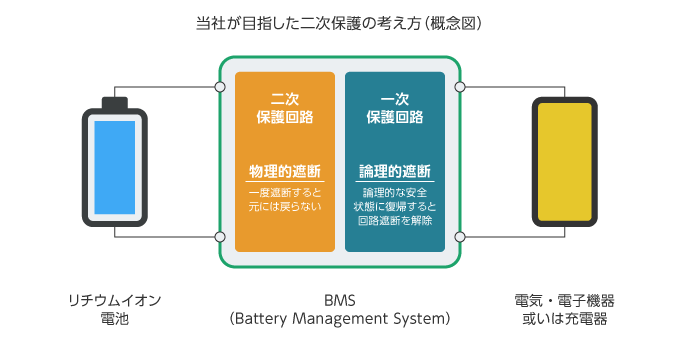

リチウムイオンバッテリーに異常が発生した場合、BMS(Battery Management System)の一次保護回路が対応しますが、万が一のために二次保護も必要です。当初、ソニーケミカルは結露センサー技術を応用し、PTCサーミスタのような保護素子を開発しようとしましたが、実現には至りませんでした。

新しい方法で回路遮断にブレークスルー

既存の技術ではなく、『全く新しい方法で回路を遮断する』という考え方が、SCPのブレークスルーを生み出しました。従来のセンサー技術で回路を遮断した場合、温度が元の状態に戻れば、ふたたびその回路は使えるようになります。しかし、一次保護が機能しない状態で、過充電、過電流が一度でも起きたリチウムイオン電池を使い続けることは危険です。そのため、回路を完全に遮断するという方向へ発想を転換して、新たな開発がスタートしたのです。

さまざまな試行錯誤を重ね、最終的に採用されたアイデアが、「回路にヒーターを組み込み、ヒーターの熱でヒューズを溶断する」という仕組みでした。この方式を採用したのは「過充電」と「過電流」の両方のトラブルに対応することが出来、なおかつ物理的に回路を遮断することができるからです。

最初に「SCP」の電気的構造を回路図で示します。左は一般的な回路図で使用される等価回路図、右は「SCP」の内部構造を反映させた3次元的回路図になり、実際の「SCP」はヒーター(抵抗器)の上にヒューズが立体交差する形で配置された構造となっています。

ここからは3次元的な回路図を使って「SCP」の動作について説明します。

放電、充電が正常に行われている際の電流の流れを以下に記します。

電子回路の短絡などで過電流が発生したときには、ヒューズエレメントがジュール熱で溶断され回路が遮断されます。

過充電の状態、すなわちバッテリーが過充電になると二次保護ICが異常を検知、ヒーター回路のスイッチになるFETをON状態に変更します。このときT1、T3の両方向からヒーターに電流が流れ発熱します。この熱がヒューズエレメントに伝わりヒューズが溶断、回路が遮断されます。同時にヒーター回路も切断されることになり、ヒーターの発熱もここで停止、「SCP」の保護動作が完了します。

当初この回路はフレキシブルプリント基板(FPC)を基材としたものが採用されていましたが、表面実装に対応するため、基材となる材料をセラミック基板に変更しています。こうして、「SCP」の原型が完成したのです。

広がり続けるリチウムイオンバッテリーと「SCP」の需要

1994年、私たちは「SCP」のヒーターとヒューズの積層構造について基本特許を取得し、同じ年に二次保護回路に「SCP」を搭載したリチウムイオンバッテリーが上市されました。「SCP」による二次保護機能を持ったリチウムイオンバッテリーはすぐに多くのコンピューター・メーカーの製品に採用され、現在もノートPCなど多くの製品でデクセリアルズの「SCP」がリチウムイオンバッテリーの二次保護回路用ヒューズとして採用されています。

発売から約30年、「SCP」の需要はリチウムイオンバッテリー市場の拡大にともなって広がりを続けています。現在はノートPCのバッテリーだけでなく、大型の電気製品、コードレス電動工具や産業用の蓄電池、電動アシスト自転車、電動バイクなどに多くのリチウムイオンバッテリーに使われるようになりました。小型バッテリー向けではノートPCやタブレットPC、さらに急速充電が可能なスマートフォンにも2016年から採用されているほか、医療機器のAEDにも搭載されています。自動車をはじめとする世界のモビリティの動力源は、ガソリンエンジンからモーターへの移行が始まっており、それと歩調を合わせて「SCP」も大型化・大電流への対応が求められています。

このように、時代によって技術のニーズは目まぐるしく変わり続けます。デクセリアルズでは、これからも多様なニーズに対応するため、想像力と技術力を活かして製品開発を続けていきます。

関連記事

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら