- 電子部品関連

ドローンの歴史と未来——高性能化・長時間化・高電圧化とその対応技術

目次

ドローンの進化と飛行タイプの変遷

ここ10年ほどで、「ドローン」という名詞はすっかり一般的となりました。皆さんも「ドローン」と聞けばすぐに「ローター(回転翼)が付いたラジコン」を思い浮かべることでしょう。ドローンを飛ばし、それに搭載されたカメラで撮影した空撮映像を見ることも、今ではすっかり珍しくなくなりました。

その「ドローン」という名前ですが、もともとは「オスバチ」を意味する「Drone」という英語の言葉になります。ドローンとは通称で、正式名称としてはUAV(Unmanned Aerial Vehicle)と呼ばれ、一般的に「無人航空機」のことを意味します(これに対し、人が搭乗して操縦する航空機を有人機と呼びます)。現在は大きさに関わらず無人で飛行し、遠隔操作ができる航空機のことを、一般にすべてドローンと呼びます。

世界で最初にドローンと呼称された無人航空機は飛行機タイプのものでしたが、現在主流なのが、ヘリコプターのようなローターを搭載した回転翼機タイプの機体です。ローターが4つ搭載されているものは「クワッドコプター」、6枚ローターは「ヘキサコプター」、8枚ローターは「オクトコプター」と呼ばれますが、これら3つ以上の複数のローターを搭載した機体を総称して「マルチコプター」と呼びます。現在、ドローンというとこうしたマルチコプタータイプのものが一般的になっています。

ドローンの拡大の歴史

ここからは、ドローンの普及拡大の歴史について見ていきましょう。1980年代から大学などの研究機関では、電動式のクワッドコプターの開発が進められていました。しかし当時は電池の容量が少なく、また小型・高出力のモーターの入手も困難だったため、有線で給電する方式でした。1987年になると、日本企業が世界初の産業用無人ラジコンヘリコプターの販売を始めました。その機体の見た目はヘリコプターでしたが、無人機であったことから、ドローンに分類されています。

1989年以降、「ジャイロスコープ」が搭載されたマルチコプターが発売されたことを契機に、産業用途を中心にマルチコプターの普及が始まります。ジャイロスコープは物体の回転や向きの変化を角速度として検知できるセンサーで、これによりドローンの姿勢や運動の制御のレベルが飛躍的に高まることになりました。

2000年代後半にはジャイロスコープや加速度センサー、リチウムイオンバッテリーなどの現在のドローンに必要な電子部品がスマートフォンに採用されるようになり、大量生産によって比較的安価で調達できるようになったことで、ドローンの開発・普及が進みました。スマートフォンやデジカメの手ブレ補正などにも、このジャイロスコープが活用されています。加速度センサーは「一定時間のうちに機体がどれだけ動いたか」を検知するセンサーで、機体にかかった重力・振動・衝撃もわかります。カーナビで車の移動距離を検知するために用いられているのも加速度センサーです。

2010年に発売されたクワッドコプターが大ヒットしたことを受けて、民生用途でのドローンの普及に弾みがつきました。クワッドコプターはよりローターの多いマルチコプターと比較して、モーター数が少ないため機体が軽量化しやすく、コストも安く、小型のバッテリーで航続距離を伸ばすことが可能です。そうした背景から、さまざまな企業が市場に参入し、民生用途やホビー用途で市場が拡大していきました。

また、この頃から、ドローンにカメラジンバル(回転台)を導入した製品が空撮用に広く普及し始めました。空撮や高所撮影にドローンを活用することで、クレーンや高所作業車などの重機を利用する必要がなくなり、メディアや映像制作における空撮コストの削減が進みました。ドローンによる空撮は高所撮影だけでなく、オリンピックなどのスポーツ実況においても今まで撮影できなかった場所やアングルでの撮影が可能になり、映像革命が起きています。

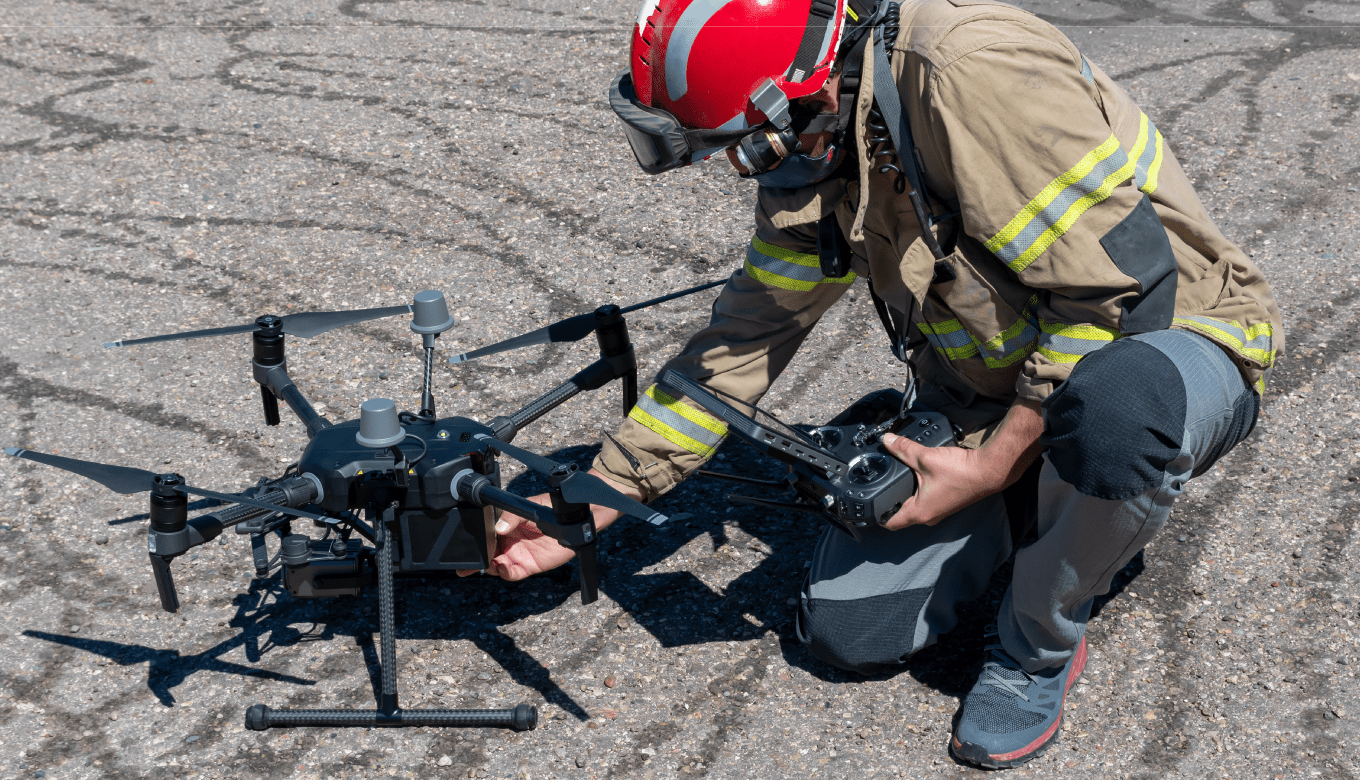

カメラ搭載ドローンの普及によって、山中のダムの壁面や橋、煙突、建設現場、プラントの配管や建物の屋根など、なかなか人が行けない場所の映像を遠隔地で確認できるようにもなりました。そうした産業用途ドローンは、業務効率の向上にも大きく貢献しています。その他にもドローンは現在、遠隔地の点検、監視、調査、結婚式などの記念撮影などにも利用されています。

農業においてもドローンの活用は広がっています。ドローンでの農薬散布や、地表温度の測定、農作物の発育具合の判定、害虫有無の確認、収穫量の予測などもドローンにサーモカメラやセンサー、特殊なカメラを装着させ、AIと連携することで管理することができるようになってきています。ドローンを活用することで、農作業の時間短縮、害虫などの防除効果の上昇、作物の品質向上にも繋がると期待されています。

こうした産業・農業用のドローンは、ローター数が6つないしは8つのマルチコプターが多く使われています。ローターが4つのマルチコプターは、その一つの系統でトラブルが発生するだけで墜落する可能性があるため、より安全性が求められるためです。

他にもエンターテイメント用途として、ドローンを使ったレースが各地で開催されています。大会では競技参加者がドローンを遠隔で操作しながら、決められたコースを飛行させる速度を競います。競技参加者はヘッドマウントディスプレイを装着して、時速100kmを超えるスピードで飛ぶドローンのカメラから送られてくる迫力ある映像をリアルタイムで見ながら、機体を操作します。

ドローン技術の進展における課題

ドローン技術が進化を続ける中でも、依然としていくつかの重要な課題が残っています。バッテリー性能の向上、安全機能の強化、そして規制の壁を乗り越えることが求められています。これらの課題に対応することが、産業用途および消費者向け用途におけるドローンの導入には不可欠です。

ドローン用バッテリーとは?

ドローンに使用されるバッテリーは、リチウムイオン電池やリチウムポリマー電池が一般的です。これらのバッテリーは高いエネルギー密度を持ち、長時間の飛行を可能にします。しかし、過充電や発火を防ぐために、二次保護ヒューズのような安全機能とのバランスを取ることが重要です。

ドローン用バッテリーはどれくらい持つか?

一般的なドローンの飛行時間は10分から30分ほどです。産業用ドローンでは、より高いエネルギー密度が必要とされ、同様の飛行時間を実現するためには、バッテリー容量や機体の軽量化が重要な要素となっています。

バッテリー電圧の上昇がドローンの飛行時間を延長する方法

バッテリー電圧の最適化により、バッテリー容量を単純に増やさずとも飛行時間を延長することが可能です。次世代のバッテリーは、エネルギー密度や寿命の面で大幅な改善が期待されています。

最も長持ちするドローン用バッテリーとは?

ドローンに使われるバッテリーの中で、最も長持ちするのは高エネルギー密度を持つリチウムイオン電池です。特に産業用途では、バッテリー寿命が飛行時間や作業効率に直結するため、長寿命バッテリーの選定が重要です。飛行時間を最適化するためには、バッテリーの容量や効率だけでなく、機体の設計や搭載機器の電力消費も考慮する必要があります。

バッテリー寿命の長いドローンを作るにはどうすればいいか

バッテリー寿命の長いドローンを作るためには、バッテリー電圧の最適化、軽量化された機体設計、そして効率的なエネルギー管理が鍵となります。加えて、最新のバッテリー技術を採用し、電力消費の大きなセンサーやカメラの使用を最小限に抑えることも効果的です。飛行時間の延長には、バッテリーだけでなく、全体の設計と技術の最適化が求められます。

ドローンに期待される「ラストワンマイル」の配送

今後、利用の拡大が望まれているのが「ドローンによる配送」です。ここ数年、大手のEC業者などが中心になって、ドローンを活用した「ラストワンマイル」のための商品配送サービスの構想を検討し始め、実証実験などが進められています。EC業界や物流業界におけるラストワンマイルとは、物流の最終拠点からエンドユーザーへと物を運ぶサービスのことを指します(「最後の1マイル」という距離的な意味ではなく、お客様へ商品を届ける物流の最後の区間のことを意味します)。

世界最大手のECサイトを運営する企業が2013年にラストワンマイルに対してドローンを利用する方針であることを表明して以降、主にアメリカで検討と実証実験が進んできました。しかし、ドローンを商業目的に屋外利用する場合は、連邦航空局(FAA)による特別な許可が必要となることもあり、実現までには時間がかかっています。

2022年になって、実現に向けて大きく前進しているという報道(Amazon Prime Airの事例)もありました。国土の広いアメリカでは、近隣のスーパーマーケットまで車で1時間以上かかる場所に住む人も多いことから、ドローンによる宅配サービスが実現することは、配送側にも消費者側にも大きなメリットがあるといわれています。また、アメリカではドライバー不足が深刻化するとともに、都市部では交通渋滞が長年の問題となっており、その2つの問題をドローン配送が解消できる可能性があります。アメリカだけでなくニュージーランドでも近年、ピザの宅配にドローンが試験的に使われ、近い将来のサービス開始が検討されています。

日本でも今後、過疎化や高齢化、ドライバー不足、インフラやサービスの老朽化がさらに進むことは確実です。そのため地方自治体や山間部、離島などに、医薬品や日用品をドローンで運ぶことが期待されており、試験飛行が始まっている地域があります。ただし日本では航空法により、人口集中地区(主に、都市部)や一定の空域でのドローンの飛行について規制があるため、実証実験が進まない現状もあります。2022年12月に入り、日本でも改正航空法が施行され、これにより2023年春以降、実証実験が開始されるという報道もありました。(報道発表資料:航空法等の一部を改正する法律案を閣議決定

~航空ネットワークの確保と航空保安対策、ドローンの更なる利活用を推進! (mlit.go.jp))日本の都市部での実証試験やそれを元にした実用化にはまだ時間がかかる見通しです。

こうした背景から、今後より一層ドローンが普及するためには、法規制に関する議論がより進むこと、また、商業用のドローンの安全性の向上が望まれています。ドローンを規制する法律としては航空法以外にも、小型無人機等飛行禁止法で国の重要施設などの周辺の飛行禁止、ドローンに使用される無線設備の電波法による規制、また、地方公共団体の条例による特定地域、空域の飛行禁止、無人航空機の飛行禁止を表明している個人の住居、邸宅や建造物の上空飛行などが定められ、実証試験ではそれらを考慮する必要があります。

また、ドローンを活用することでさまざまなメリットがある一方、墜落事故などの安全面の問題や、他人の住居を覗き見るといった、プライバシーを侵害する用途で使われかねない課題もあります。ドローンの安全・公正な利用を推進するために、ドローンを運用する事業者同士の運行を管理するシステムの整備や、ドローン操縦者の育成と安全教育、電波の整備、飛行ルートの確保など、これからさまざまな課題をクリアしていく必要があります。

ドローンに使われる電池とその課題

ここからは、ドローンに使用されている電池について解説します。民生用の小型のドローンは一般的に、充放電が可能な二次電池(バッテリー)が採用されており、リチウムイオンバッテリーやリチウムイオンポリマーバッテリーが使われています。

特にドローン用途で多く使われているのが「リチウムイオンポリマーバッテリー」です。この電池は、リチウムイオンバッテリーの材料である電解質がポリマー状になっているものを指します。リチウムイオンポリマーバッテリーは軽いことから、もともと機体の軽さを求められるラジコン飛行機などで多く使われてきました。

リチウムイオンバッテリーには原理的に「熱暴走により発火に至るメカニズム」があります。通常の使用温度の範囲内でも「何らかの理由」 が加わることで、連鎖的な発熱反応が起こって温度が急上昇し、発煙・発火 に至る場合があります。このため市販されているリチウムイオンバッテリーでは、保護回路などの安全設計が必須となっていますが、それでも、実際には事故の報告がなくなったわけではありません。

現状では、ドローンに電池を搭載する場合、上記のことを踏まえ、リチウムイオンバッテリーの性質に対する十分な知識をもって取り扱わないと、火災などが起こるリスクが高くなります。落下や衝撃が加わると、セルが変形し、内部ショートという発火の引き金となる場合があります。また、マルチ充電器対応(設定条件をユーザで変えることができる充電器)の場合、セルバランスのずれや充電設定電圧の間違いにより、過充電という引き金となる点に注意が必要です。

飛行の長時間化にともなう電池の高電圧化

また、今後ドローンが空撮以外のさまざまな用途で広く普及するにあたっては、約30~40分と飛行時間が短いことが大きな課題になっています。これはバッテリー容量に限界があることが大きな原因です。ドローン用バッテリーには飛行開始から、着陸に至るまで、安定して飛行し続けるために、必須となる出力特性を維持することが求められます。そのため、今後のドローン用バッテリーにはこの出力特性を維持したまま、エネルギー密度を向上させることが求められています。

ただし、バッテリー容量を単純に増やしてもバッテリーそのものの重量も増えるため、飛行時間は一定以上増えません。そのため、より一層の飛行時間の延長には、機体の軽量化と、バッテリーそのものの特性の向上が求められています。

こうした背景により、リチウムイオンバッテリーの充電電圧の高電圧化や、内部抵抗の低減に多くのメーカーが取り組んでいます。電池の重さあたりのエネルギー量増加がドローン飛行時間の増加に直結するため、セルの高容量化、質量低減、密度向上、最大出力密度向上などが求められています。また、低温環境や高温環境など、さまざまな温度環境で安全に使用できること、バッテリーの長寿命化なども課題となっています。

現在、次世代電池の開発目標では、充放電回数が1,000回以上、エネルギー密度が400Wh/kgというレベルに2020年代後半から30年代に到達すると言われています。

電池の性能向上によってドローンの飛行時間は大きく伸びます。例えば、現行のドローンが250Wh/kgで30分の飛行時間とすると、同じバッテリーサイズで400Wh/kgなら48分、500Wh/kgなら60分、1,000Wh/kgだと120分の飛行が可能です。配送ドローンの場合、60分を超えてドローンが飛べるようになると、充電のための拠点を増やさずに現在の配送エリアをすべてカバーできるようになると言われています。(日本国内・ペイロード2kg想定)

近年は一つの電池パックにセルを10本以上接続することで数10Vの高電圧を実現したリチウムイオンバッテリーが開発され、それをドローンに採用することが検討され始めています。そうした高出力の電池をドローンに使用するにあたって重要となるのが、万が一の事故を防ぐ安全対策です。

リチウムイオンバッテリーに万が一の過充電などのトラブルが起きたときに、安全に回路を遮断する機能を持つ素子が、デクセリアルズの開発したセルフコントロールプロテクター(SCP)です。SCPについてはこちらの詳しい解説記事もご参照ください。

次世代ドローンを保護する、高電圧対応の二次保護ヒューズ

デクセリアルズが開発したセルフコントロールプロテクター(SCP)は、リチウムイオンバッテリーの二次保護回路において、物理的に充放電回路の不可逆的な遮断を行うヒューズ部品です。二次保護のためのヒューズ素子である「SCP」が動作するのは、バッテリーに組み込まれた一次保護機能が正常に機能せず、リチウムイオンバッテリー全体が危険な状態にあるときです。充放電の制御が不安定なリチウムイオンバッテリーが動作し続けることがないよう、あえて回路を遮断し、安全に使えなくすることが「SCP」の役割です。

一般的にヒューズと呼ばれる素子は、回路に過大な負荷(電流)がかかった際にジュール熱でエレメントが溶断することで、回路を物理的に遮断し過電流から機器を守る部品です。ただし、リチウムイオンバッテリーの場合、過電流だけでなく過充電にも対応する必要があります。過電流・過充電の両方への対応を可能にしたのが「SCP」です。1994年の発売以来、リチウムイオンバッテリーの二次保護用ヒューズの標準的な部品として認知され、25億個以上(2022年3月現在)を出荷しています。

リチウムイオンバッテリーは過充電状態になると、プラス極での材料の結晶分解、マイナス極では熱的不安定な金属リチウムが析出するなど、事故の引き金となる反応が発生し、発火・破裂に至る可能性があります。また、過放電にともなって金属材料が溶け出すこともあり、その場合、その次に充電した際には金属析出となって、ショートする可能性があります。

そのため、リチウムイオンバッテリーの保護設計思想としては、過充電および過放電の両方ともに充放電を停止する制御(保護)をすることが基本的な考え方となります。

ドローンの場合、飛行中に過放電に至らないように電力供給を停止させると、ドローンが墜落してしまう可能性もあります。そのため、外部からの衝撃などでショートの可能性が常にあるドローンでは堅牢性の高いリチウムイオンバッテリーがより適していると言えます。必要な性能を得るためには一定程度セル同士を接続することが必要ですが、同時にショートの危険を回避し、過充電などによる事故を未然に防ぐ回路を実装しておくことが必要です。 以下記事にある通り、充電回路と放電回路を分けて考え、充電回路のみにヒューズを搭載することで電力供給停止時に墜落する心配もなくなり、安全対策も可能となります。

以下参考記事:リチウムイオンバッテリーの大電流化に対応する二次保護ヒューズ(SCP)の技術

関連記事

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら