- 光学関連

手術室の感染対策に欠かせない個人用保護具(PPE)とは―種類と特徴、そして進化するフェイスシールド

【免責事項】

本記事の内容は、一般的な技術情報および市場動向の紹介を目的としたものであり、特定の医療行為・治療方法・診断・処方を推奨するものではありません。

記載されている情報は、医療従事者または医療機器関連事業者向けの参考資料として提供しています。一般消費者による医療判断や使用目的での参考はご遠慮ください。

本記事に記載された製品・材料・技術については、必ずしも医療機器として薬機法上の認可を受けているものではありません。実際の使用にあたっては、各国・地域の法規制および承認状況をご確認ください。

また、記事内容は執筆時点の情報に基づいており、将来的に変更される可能性があります。

目次

個人用保護具(PPE)の役割とは?

手術室のような高リスク環境において、医療従事者の安全を確保し、感染拡大を防ぐうえで欠かせないのが個人用保護具(PPE:Personal Protective Equipment)です。PPEは医療スタッフ自身だけでなく、患者を守るためにも非常に重要な装備であり、適切な選定と運用が求められます。ここでは、手術室で使用される主なPPEの種類と、それぞれの使用目的や注意点について整理します。

手術室で使われるPPEの種類とその使い方

PPEには複数の種類があり、それぞれが異なる役割を果たしています。以下に代表的なPPEとその特徴をまとめます。

| PPEの種類 | 特徴 |

|---|---|

| 手術用ガウン | 医療スタッフと患者の間での交差感染を防ぐための防護衣です。滅菌済みの手術着の上から着用し、手術ごとに交換します。 |

| サージカルマスク | 飛沫や体液の飛散から口や鼻を守るためのマスクです。患者ごとまたは湿った場合に交換します。 |

| フェイスシールド | 顔全体を覆うことで、目や皮膚への飛沫接触を防ぎます。特に飛沫の多い処置ではマスクと併用して着用されます。 |

| 医療用手袋 | 手と患者との直接接触を避けるための手袋です。患者ごとに交換し、再使用は認められていません。 |

| ヘアカバー(キャップ) | 毛髪や皮膚片の落下を防ぎ、手術環境の無菌状態を保つキャップです。全スタッフが着用し、手術ごとに交換します。 |

| シューカバー | 靴底に付着した微生物が手術室内に持ち込まれることを防ぎます。手術区域に入る際に着用し、手術ごとに交換が必要です。 |

| N95マスクなどの呼吸用防護具 | エアロゾル感染のリスクがある処置(例:挿管)時に使用される高性能フィルター付きマスクです。 |

フェイスシールドに求められる新たな機能

手術室での作業には、視界の確保が不可欠です。特に反射や視野の歪みによる作業精度の低下は、患者の安全に直結します。そこで注目されているのが、デクセリアルズが開発した反射防止フィルム モスアイタイプを用いた手術用フェイスシールドです。

このフェイスシールドは、表面に施された微細構造によって反射光を抑え、照明下でも鮮明で見やすい視界を提供します。視認性の向上により、作業の精度とスピードが高まり、長時間の使用でも目の疲れや負担が軽減されます。

(反射防止フィルム モスアイタイプに関する詳細はこちらの記事をご覧ください。)

透明なフィルムで、額から顎までの広い範囲をカバーし、側面まで保護できるタイプもあります。防護性能のみならず、高い視認性も実現する当社の手術用フェイスシールドは、医療従事者の作業精度の向上に貢献します。なお、使用後は病院の消毒・洗浄手順に従って処理され、多くの場合は使い捨てとなります。劣化や破損が見られた場合には速やかに交換する必要があります。

フェイスシールドを支える微細加工技術とは?

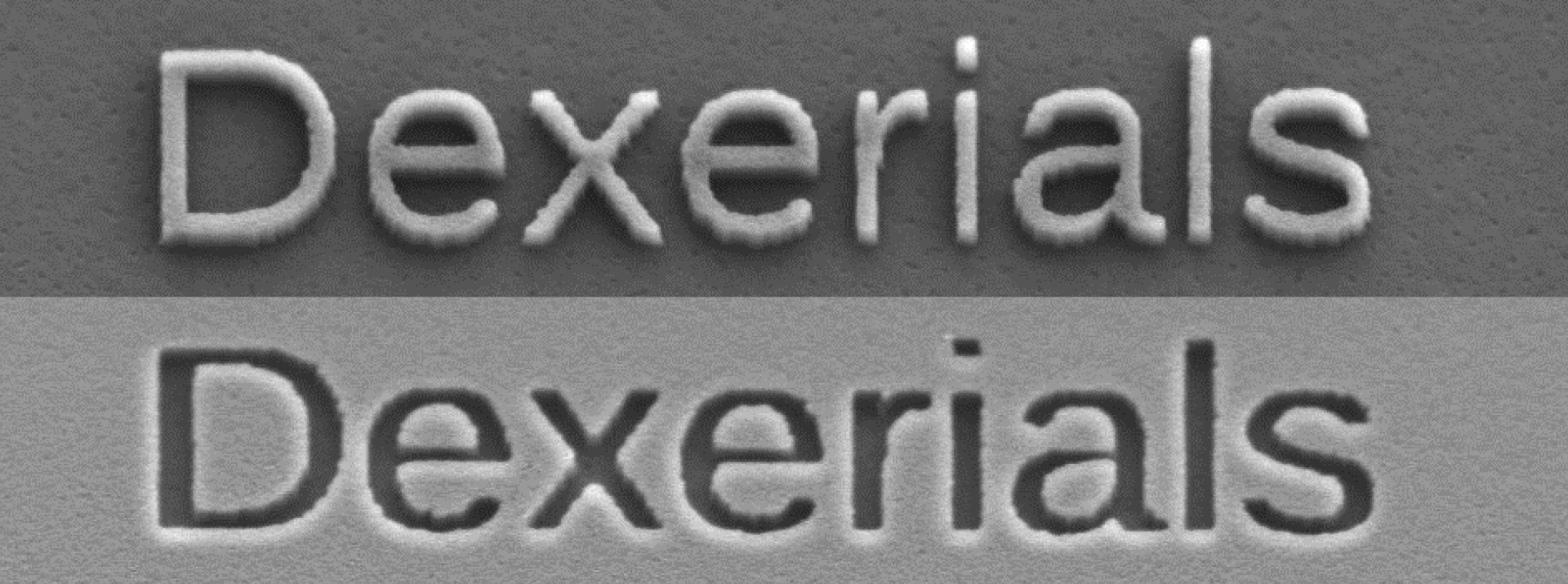

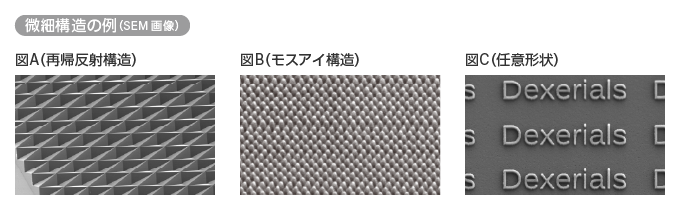

高視認のフェイスシールドに使われる射防止フィルム モスアイタイプの中核にあるのが、デクセリアルズの微細加工技術です。この技術では、フィルムや樹脂シート、ガラスなどの基材表面を削り、材料を積層することで、数百ナノメートルから数百マイクロメートルの微細構造を形成し、光の反射を制御するなどの機能を付加します。

この微細加工を支えているのが、デクセリアルズ独自のロールtoロール転写技術です。

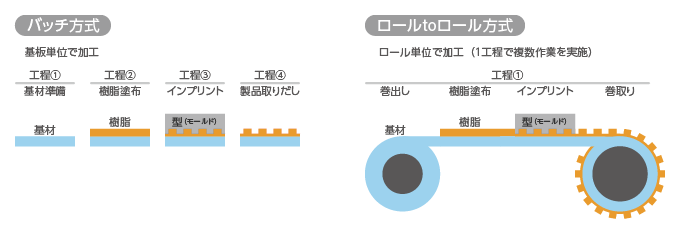

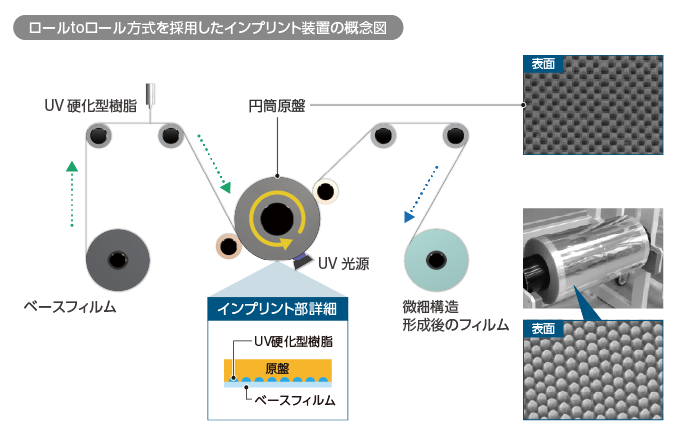

「ロールtoロール方式」とは、数百メートル単位で巻かれたフィルムなどの基材を連続的に加工しながら供給・回収する生産方式です。従来の「バッチ方式(平板単位での加工)」に比べて、長尺材料を一貫して加工できるため、高効率な量産が可能となります。

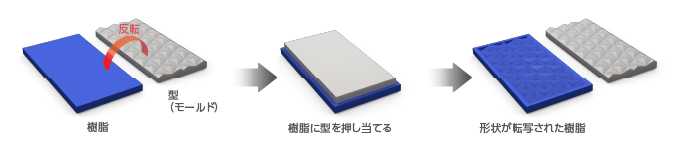

さらに、デクセリアルズの微細加工技術では、このロールtoロール方式に「インプリント技術」を組み合わせています。インプリント技術とは、金属やガラスで作られた「金型(モールド)」を、樹脂などの柔らかい材料に押し当てて形状を転写する技術です。

下図は、樹脂を金型に押し当てて形状を転写する様子を示しています。

この原理と同様に、円筒形のモールドを用いて、フィルムや樹脂シートなどの基材に対し、高精度な微細構造を連続的に形成することができます。

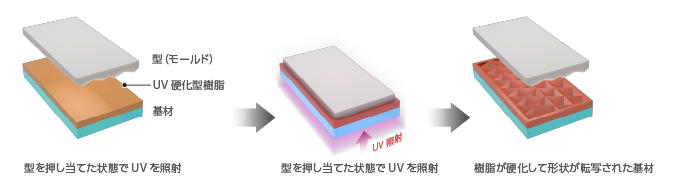

特に「UVインプリント」では、紫外線(UV)で硬化するUV硬化樹脂を基材表面に塗布し、金型を押し当てながらUVを照射します。これにより、金型のパターンがそのまま樹脂に転写され、微細構造を備えた表面が形成されます。モールドを取り外すと、パターンが反転した状態でフィルム表面に残ります。

以下に、ロールtoロール転写技術の模式図を示します。

まず、ロールから供給された基材フィルムに、ディスペンサーを使ってUV硬化樹脂が塗布されます。その後、塗布された樹脂部分が、円筒形の金型と接触しながら通過する工程に入り、その間にUV照射によって樹脂が硬化されます。これにより、マスタリングプレート上と同様の微細構造がフィルム表面に形成され、最終的に製品として再びロール状に巻き取られます。

この工程においては、マスター基板に離型処理(モールドリリース処理)が施されており、硬化した樹脂がきれいに剥がれるよう設計されています。この高精度な加工を実現するには、次のような複数の技術要素が必要です。

- 円筒形マスターの高精度な微細加工技術

- 装置内の湿度・温度管理

- UV照射の制御

- ロール搬送の精密な制御

- 樹脂の厚さ、組成、粘度の均一化

これらを高度に統合して制御することで、安定した品質と量産性が両立されます。

デクセリアルズは、ロールtoロール転写技術による微細加工の分野で長年培ってきた知見を活かし、安定した加工品質と高い量産性を実現しています。(ロールtoロール方式のインプリント技術に関する詳細はこちらの記事をご覧ください。)

医療現場のニーズに応えるPPEの進化──高視認性と安全性の両立へ

手術室をはじめとする医療現場では、感染防止と安全性の確保が常に最優先されます。個人用保護具(PPE)はそうしたニーズに応えるための基本的な手段であり、その正しい選定と運用が求められます。

なかでもフェイスシールドは、飛沫や接触からの保護に加え、作業精度に直結する「視認性の確保」という役割も担っています。デクセリアルズのフェイスシールドは、独自の微細加工技術と光学制御機能により、安全性と視認性を両立する次世代型PPEとして進化しています。

このようなPPEの高度化は、現場の医療従事者の負担を軽減し、患者の安全をより確実なものにする取り組みの一環です。今後もデクセリアルズは、材料技術と精密加工技術を活かし、医療現場の課題解決に貢献していきます。

関連記事

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら