- Optical Products

Advantages of Medical Shields with Moth-eye type Anti-reflection film

Contents

The problem with using medical eye or face shields: eye fatigue

With the spread of COVID-19, the demand for protective equipment called “medical shields” has been increasing since the beginning of 2020. Face shields cover the face to reduce the risk of droplet transmission. It also reduces the risk of touching one’s eyes, nose, or mouth with hands exposed to biological contaminants such as viruses and bodily fluids.

Most medical face shields are made with a transparent films such as PET. These films can sufficiently protect from droplets, but there is room for improvement when considering their use in the medical field, especially in the operating room. In general, PET film has a transparency of about 90% and a light reflectance of about 8%. These characteristics may not be a concern for short-term use, but the reflected light and glare from the film may cause eye fatigue during long-term use. In addition, exhaling can cause the film to fog up, obstructing quick and accurate work.

Several years ago, a doctor at a hospital commented to Dexerials that “If possible, we would rather not use the current protective equipment (eye shields and face shields), because they reflect light and reduce visibility. Can you make shields that are easier to use by applying the Dexerials’ anti-reflection film?” This comment prompted Dexerials’ to start developing low-reflectance and high-transparency films for medical shields.

As a result, Dexerials’ developed and launched a high-transparency film for medical shields in 2014. It was designed for use in operating rooms where reducing eye fatigue and being able to wear for a prolonged period of time is critical. Due to the current spread of COVID-19 infections, there is an increase in demand for protective equipment, not just in the medical field.

Excellent optical properties due to moth-eye structure

The term “moth-eye type” refers to the fact that it mimics the structure of a moth’s eye. The surface of a nocturnal moth’s eye has uniformly arrayed nano-level bumps, which allows the moth to fly at night with the slightest bit of moonlight. Dexerials has artificially formed the moth-eye structure on a film using its proprietary technology, and has applied it to anti-reflective films for displays and other applications.

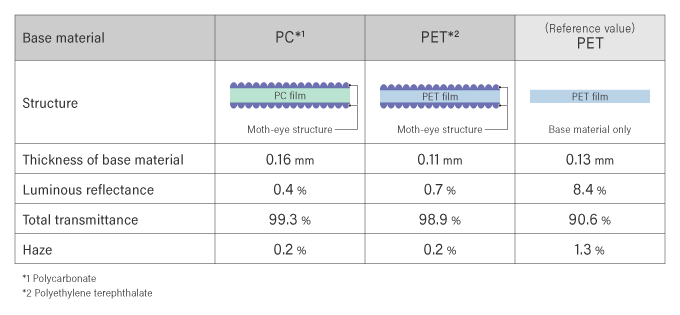

Dexerials’ films with moth-eye structure on both sides of the base film to achieve low reflection and high transparency of medical shields. The figure below shows a comparison of the optical properties of medical shield products.

While the luminous reflectance of conventional shield film (base material: PET) is 8.4%, Dexerials’ film with moth-eye structure has a 0.4% reflectance with a PC (polycarbonate) based material. The total transparency with the PC-based material was 99.3%, compared to 90.6% with the conventional film. The amount of light scattering (haze) was also 0.2% compared to 1.3%, indicating a significant improvement in all categories. Even the moth-eye film using a PET-based material performed better than the conventional film.

Advantages of face shields film with moth-eye structure

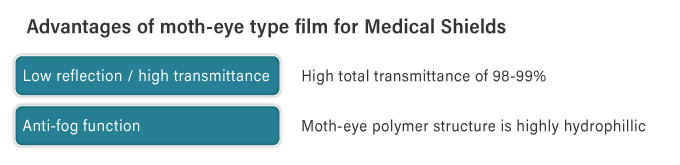

There are several advantages to using a face shield with a moth-eye film on both sides. With a total light transmittance of 98-99%, which is much higher than that of conventional PET shields, it can significantly reduce eye fatigue during hours of extended use. In fact, in a survey of medical professionals who wore medical shields with Dexerials’ moth-eye film, several stated that they forgot they were even wearing the medical shield and could fully concentrate on their operation.

Another advantage of Dexerials’ moth-eye type anti-reflective film is its anti-fog function. Face shield fogging is caused by water vapor in exhaled air condensing on the film. A moth-eye structure is highly hydrophilic, so even if water vapor adheres to the film, it spreads instantly and does not form water droplets. As a result, the film is not easily fogged even when you blow on it. In the medical field, where absolute accuracy is required, some people are hesitant to wear protective gear due to concerns about reduced visibility. Overall, medical shields using Dexerials’ anti-reflection film moth-eye type have been highly evaluated in the medical field.

Expansion of Medical Shield to other industries

Currently, the demand for medical shields is increasing as one of the measures to prevent infectious diseases. Dexerials is building equipment to increase the production capacity of moth-eye type anti-reflective film for medical shield application. Dexerials’ films are supplied to major manufacturers of medical shields in Japan and abroad. In addition, with the increase in demand in recent years, Dexerials has expanded the application of this film to other industries and fields for personal protective equipment (PPE). This includes sales and front-of-house staff where people come into contact with customers closely, production staff at food factories, schools, and the entertainment industry where many people gather. Dexerials will continue making innovative efforts to contribute to society.

- SHARE

Back to top

Back to top  Contact us

Contact us