- 要素技術

硫化・窒化技術による新材料開発の未来〜デクセリアルズが挑む無機材料技術の革新

目次

半世紀以上培われてきた、無機材料合成技術

デクセリアルズは、材料開発の中核を担うコア技術の一つとして、半世紀以上にわたり無機材料の合成技術を磨き続けてきました。この技術を基盤に、磁気ヘッド用フェライトコアやPZT系圧電材料、ガラス材料、Liイオン電池用正極材、ディスプレイ用蛍光体など、数多くの革新的な製品を生み出してきました。

硫化・窒化技術とは―無機材料の性能限界を超える新たな材料設計

酸化物材料で特性限界がみられる領域において、硫黄や窒素を組み合わせた「複合アニオン材料」の開発に取り組むことで、従来材料では実現できなかった新たな機能の創出に挑戦しています。

複合アニオン材料は、2つ以上の異なるアニオン(陰イオン、負の電荷を持つイオン)が1つの化合物内に共存している材料ことを指し、酸硫化物や酸窒化物などがこれに当たります。従来、酸化物はその安定性や量産性からセラミックスや半導体、触媒など広く使われてきましたが、酸化物ベースの材料開発はある程度成熟しつつあり、これを超える新しい材料として期待されています。

たとえば、太陽光を利用して水を分解し水素エネルギーを得る「人工光合成用光触媒」では、従来の触媒では、紫外光しか利用できず、太陽光の多くを占める可視光を活用できないという問題がありました。太陽光の約95%は可視光および赤外光で構成されており、紫外光が占める割合はごくわずかです。そのため、光触媒に可視光応答性を持たせることは、太陽エネルギーの利用効率を高めるうえで極めて重要です。デクセリアルズが取り組む新しい人工光合成用材料(光触媒)の開発では、酸化物触媒に硫化・窒化技術を取り入れ複合アニオン化することで、可視光領域の光も人工光合成に活用することを目指しています。

このように、硫化・窒化を活用した材料設計は、既存材料の性能限界を超えるだけでなく、まったく新しい機能性材料の可能性を拓くアプローチとして期待されています。

これらの先端材料の開発には、硫化水素(H₂S)やアンモニア(NH₃)といった、毒性・可燃性の高い反応ガスの使用が不可欠です。デクセリアルズでは、それらの高リスクガスを安全かつ安定的に取り扱える量産対応の設備体制を確立しており、素材の社会実装に向けたスケールアップにも対応可能です。

さらに基礎研究段階の実験にも対応できるよう、反応ガスの取り扱いや焼成雰囲気の制御において柔軟な条件設定が可能な装置を整備し、新しい無機材料探索を支える技術基盤を構築しています。

新規材料開発に不可欠な均熱性──ガス流通焼成炉の設計と優位性

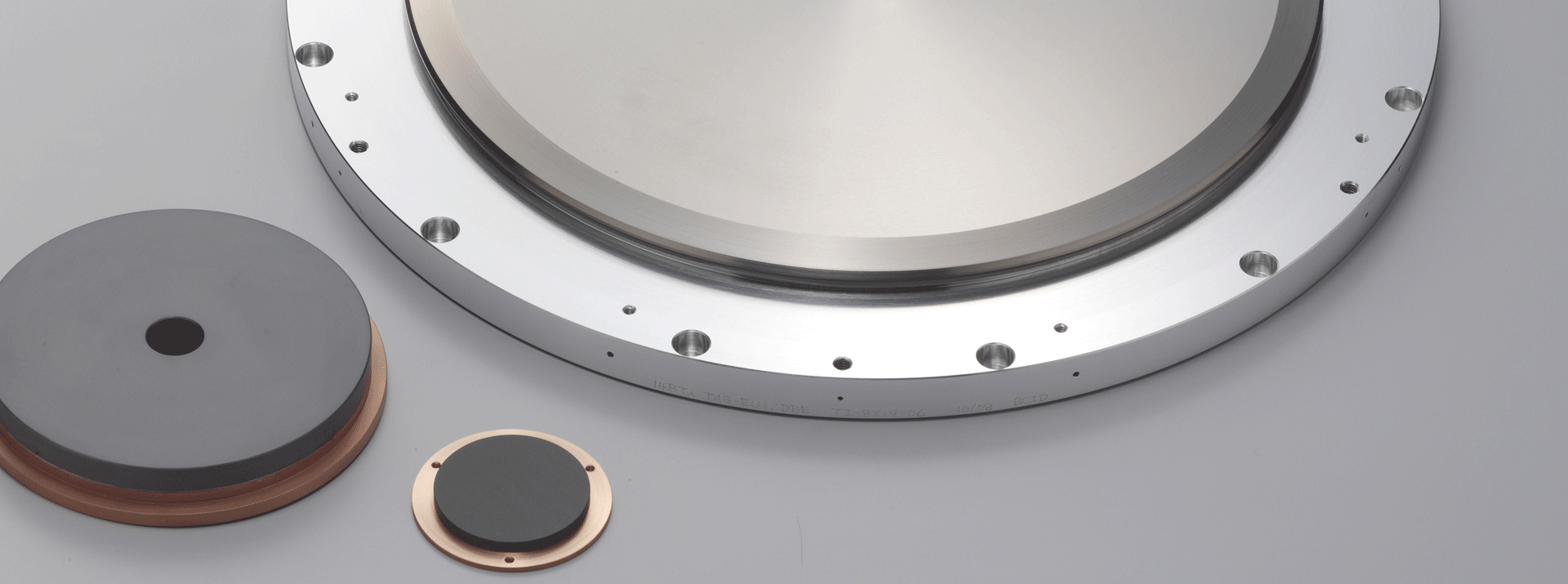

硫化・窒化材料の合成においては、焼成時の温度管理や雰囲気ガスの均一な分布が、材料特性に大きな影響を及ぼします。特に硫化水素やアンモニアのように反応性が高く、取り扱いに高度な制御が求められるガスを用いる場合、炉構造の設計そのものが反応の均一性や安全性を左右します。

デクセリアルズでは、反応ガスの流れを制御しながら、高い温度均一性を実現する構造を持つ、ガス流通法に最適化された焼成炉を保有しています。炉内には広い均熱帯が確保されており、各るつぼの位置に関わらず、同等の温度と雰囲気ガス条件を保つことが可能です。これにより、複数の試料に対しても安定した熱処理が実現され、材料のばらつきを最小限に抑えた再現性の高い合成が可能となっています。

さらに、当社の炉では試料配置の自由度にも優れた設計が施されており、たとえば、小型のセラミックス製容器(るつぼ)を多数並べ、異なる配合や焼成条件を一度の焼成で並列に評価できる「コンビナトリアル実験(条件比較型の並列評価手法)」が可能です(図左)。

また、大きなるつぼを用いて一括合成を行い、後工程に向けたスケールアップ評価にも対応できます(図右)。

当社では、前駆体の合成から焼成、後処理、特性評価までを一貫して実施できる体制を揃えており、研究初期の探索から量産を見据えた条件検討までを一つの設備で完結できる点も強みです。これにより、反応の均一性・再現性を重視するアカデミアや開発部門にとって、有用な研究基盤として活用されています。

一方で、硫化・窒化技術を応用した新規材料開発には、「高温・有毒ガス環境での合成プロセス」という大きな壁が存在します。硫化水素やアンモニアといった、毒性・可燃性の高いガスを高温環境で取り扱う必要があり、その制御には高度な設備と管理体制が求められます。当社設備はこの点でも十分な能力を持ち、反応ガスを量産スケールで安定かつ安全に取り扱う環境を実現しています。

硫化・窒化材料の応用実績──蛍光体や光触媒材料への展開

デクセリアルズの硫化・窒化技術は、すでにいくつかの実績を生み出しています。

2021年に発表したディスプレイ用の蛍光体フィルムでは、硫化物を用いた高発光効率の緑蛍光体を採用しました。これにより、ディスプレイの画質向上と薄型化に寄与する性能が高く評価されました。

また、当社は「人工光合成化学プロセス技術研究組合(ARPChem)」に第2期(2021〜2030年度)から参画し、人工光合成の実現に向けた研究開発を進めています。

ARPChemは、CO₂フリーの水素製造が可能となる人工光合成化学技術の確立を目的とした研究組合であり、企業や研究機関が連携して、光触媒材料の開発を担当しており、水分解装置の構築、安全性評価などを通じて、人工光合成の実用化に向けた技術確立を目指しています。

当社はこのプロジェクトにおいて、太陽光エネルギーを活用した水の分解による水素生成の反応効率を高め、持続可能なエネルギーの変換効率向上に貢献することを目指しています。

本プロジェクトの詳細はこちらの記事をご参照ください。

CO2等を用いたプラスチック原料製造技術開発 | NEDO グリーンイノベーション基金

産学連携で進める硫化・窒化材料の研究開発──共創パートナーを募集

2050年のカーボンニュートラル社会の実現を目指し、現在、デクセリアルズではエネルギー分野に貢献できる新機能材料の開発に取り組んでいます。太陽光変換材料、センサー用途など、多様な分野への応用を視野に入れた材料設計を進めており、硫化・窒化材料のさらなる可能性が拓かれようとしています。

材料開発において「前工程としての材料品質ばらつきが少ないサンプルが欲しい」「安全考慮し実験環境が構築できない」「一度に複数組成の実験を行い効率化したい」といった課題に、デクセリアルズの設備とノウハウは、技術開発者と共に解決に取り組む体制を整えています。

当社は、技術課題を共有し、ともに材料の未来を切り拓く共同研究・共同開発パートナーを広く募集しています。大学や企業との共創を通じて、世界の社会課題に応える新たなソリューションを共に創出していきたいと考えています。

私たちが有する「安全性」「スケーラビリティ」「コンビナトリアル」の技術基盤を活かし、これまでにない機能性材料の実現に向けて、ぜひ共に挑戦していきましょう 研究者の皆さまからのご連絡を心よりお待ちしています。

硫化・窒化技術にご関心のある研究者・技術者の皆様へ

デクセリアルズは、硫化・窒化をはじめとした硫化・窒化材料の研究開発において、オープンイノベーションを積極的に推進しています。

新たな材料探索に取り組む大学・研究機関・企業の皆さまとの連携を通じて、社会的意義のある革新をともに創出していきたいと考えています。

技術的なご相談や共創のご提案については、ぜひお気軽にご連絡ください。

ご連絡はこちらから

関連記事

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら