- 接合関連

機能性テープの評価方法

機能性テープに求められるさまざまな特性

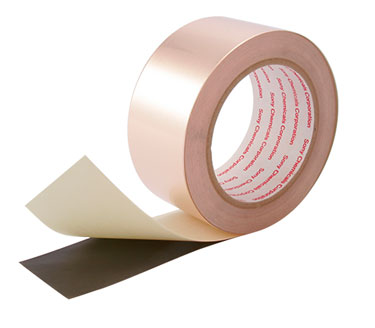

デクセリアルズの生産販売する機能性テープには、さまざまな種類とスペックがあります。どの製品がもっとも使用目的に合うか、お客さまに正しく選定してもらうために、私たちは各製品ごとにさまざまな指標で評価を行っています。

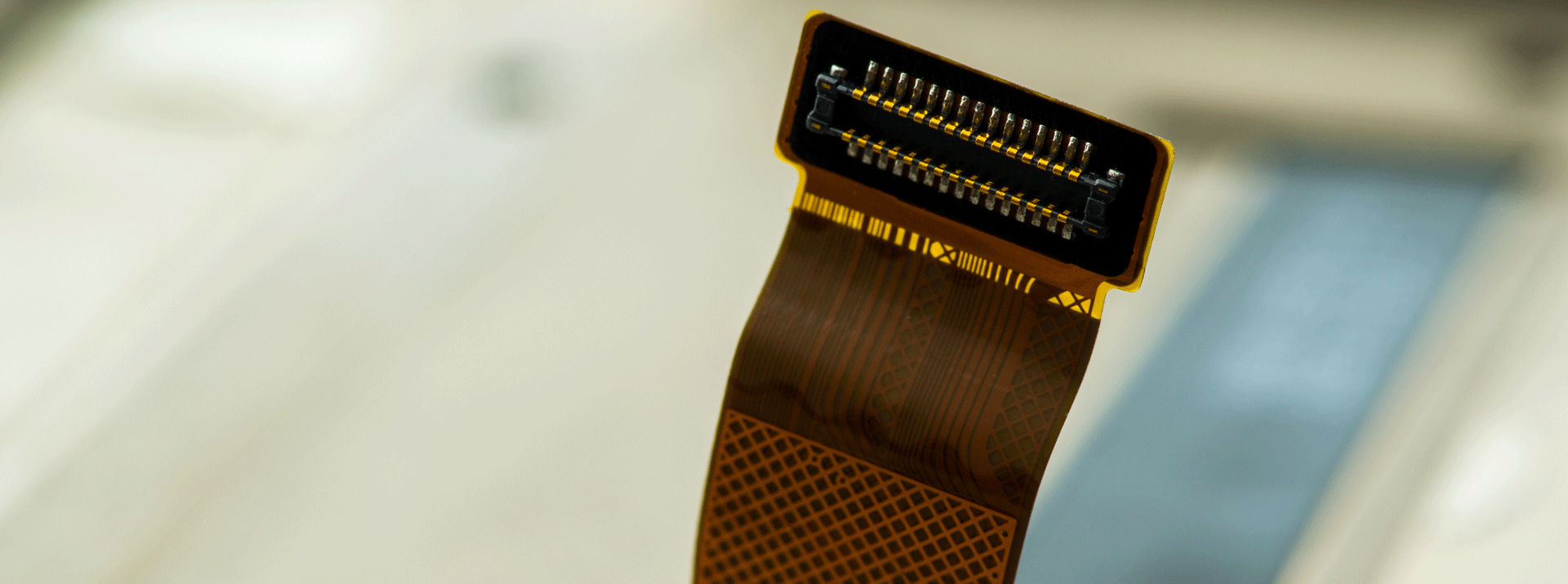

同じ「固定」という目的を果たす上でも、部品の固定であれば製造工程を意識した「耐熱性」、CPUとヒートシンクの固定では熱を逃がすための「熱伝導性」、HDDなどの精密部品では精密動作を担保する「制震性」、EMIシールド部品では「電気特性」、LCD部品では「光学特性」、デジタル機器部品では「耐衝撃性」といったように、求められる特性が違ってきます。最適な製品を選ぶためには、固定能力とともにそうした特性も、正確な数値指標で把握する必要があります。

接着(粘着)テープを選ぶときのポイント

お客さまが接着(粘着)テープを選定される際に、デクセリアルズがお聞きする主な項目は下記の通りです。

- 貼り付ける被着物の素材はなにか

- 生産環境と使用環境の温度(低温〜高温)

- 接着の要求項目(リワークのための剥離性を求めるのか、しっかり固定するために保持力が必要なのか)

- 接着の要求スペック(例えば、「40℃で10N/2cm以上」など)

- その他に必要な付加機能はあるか(熱伝導性、衝撃吸収性、電気特性など)

お問い合わせをいただいた段階で、上記のすべてが明確に確定している場合もあれば、お話を聞くなかで確定していく場合もあります。

デクセリアルズが実施するテープの評価の事例

デジタル機器の部品接着で両面テープを使用する際には、力学的負荷だけでなく、熱的負荷も考慮に入れる必要があります。特に大型テレビなどの前面板は大きいだけでなく、かなりの重さがあることから、長時間使用を想定して熱的負荷がかかった状態で重量物を支える能力を把握しておくことが重要です。この試験では、特定の温度環境下で両面テープに接着した部材に1kgの重りを接続し、1時間後の変位を見ます。重力がかかる垂直方向の保持力を評価する試験です。

この試験では、両面の粘着テープの基本的な接着力を測定します。身近な例でいえば、段ボール箱に貼り付けられたガムテープを剥がすのにどれぐらいの力が必要なのかを測る試験と言えるでしょう。「JIS Z0237」の規格が定める粘着テープの測定方法に従い、引張試験機を用いて、被着材AとBの端部を指定角度方向に一定の速度で引っ張ります。ここで、結果から強度を算出します。被着体の片方が金属などの変形しない剛体で、もう一方がPETフィルムのような、柔らかく力を加えても伸び縮みしにくい材料を貼り付ける場合に試験します。

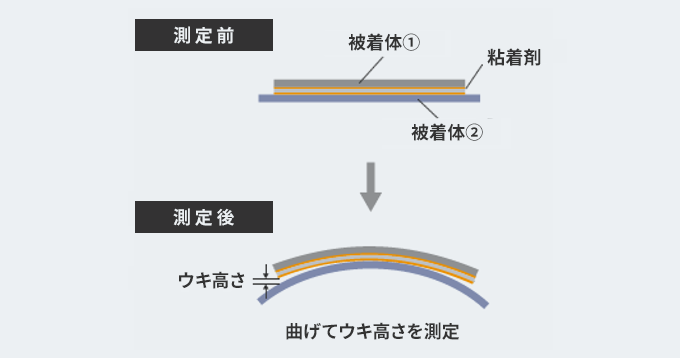

この試験で測定するのは、被着体が曲面となるような力が加わったときの接着力です。平面の板同士を接着した場合、それに曲げの力が加わると、接着部には常に剥がれようとする力がかかり続けます。試験では、一定時間経過後の剥がれ量を計測します。被着体が金属と金属なのか、片方が樹脂なのかなどによって、発生するひずみがそれぞれ違うため、具体的に生産現場で何と何をくっつけるかを明確にした上で実施します。

デクセリアルズではこの他にも、接着剤の特性ごとに、熱特性や電気特性、光学特性を測るなどのさまざまな試験を実施しています。また、お客さまのご要望に合わせて、カスタマイズした試験も日常的に行っています。私たちがいま販売する商品の多くは、お客さまの「こんな特性を持った製品はないか?」という問い合わせから生まれてきました。カタログに記載されたスペックだけではわからない疑問などがありましたら、お気軽にご相談ください。

関連記事

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら