- Electronic Components

Evolving Vacuum Cleaners and Future Safety: Protecting Lithium-ion Batteries with Surface-Mount Fuses

This article explores the history of vacuum cleaner development, focusing on the contributions of lithium-ion batteries, and explains the role of our surface mount type fuses in protecting these batteries.

Contents

- 1 Mechanism and capabilities of vacuum cleaners

- 2 Evolution and history of vacuum cleaners (from the beginning to the 2000s)

- 3 Evolution of robotic vacuum cleaners (2000s onwards)

- 4 Further evolution of vacuum cleaners and the importance of lithium-ion batteries

- 5 Role of Dexerials’ surface mount type fuse

Mechanism and capabilities of vacuum cleaners

Vacuum cleaners operate on a fundamental principle of creating negative pressure with a fan to draw in dust and debris. These particles are then separated by an air filter and collected into a container. This simple yet efficient mechanism applies broadly to home, professional, and industrial vacuum cleaners.

The primary capability of a vacuum cleaner is its suction force. When assessing this capability, “suction power” is the key indicator. This value, which measures the vacuum cleaner’s suction force, is akin to the horsepower (maximum output) of a car. However, high suction power does not always equate to superior cleaning performance. The actual cleaning performance of a vacuum cleaner also largely depends on the nozzle design. Manufacturers therefore not only strive to enhance suction power but also focus on developing efficient floor nozzles.

Generally, vacuum cleaners with higher suction power are better equipped to handle various shapes of debris and a wide range of floor materials. The suction power of a vacuum cleaner is calculated by measuring different air volumes and vacuum degrees using measuring equipment connected to the vacuum cleaner, and then determining their maximum values. The formula used is “0.01666 * volume of air (m3/min) * degree of vacuum (Pa),” with the result expressed in watts (W). In Japan, the JIS C 9108 standard requires vacuum cleaners to be labeled with their suction power, helping consumers make informed choices.

Each category of vacuum cleaner—home, professional, and industrial—has distinctive features, which are outlined below.

| Home vacuum cleaners | These vacuum cleaners are designed for use in ordinary homes and small stores. Many of them are made from lightweight plastic to facilitate easy handling. |

| Professional vacuum cleaners | These vacuum cleaners are designed for professional cleaning companies and are required for business registration. Many of them are built for durability, featuring design elements such as metal casings and motors with long lifespans. The most portion of their body is dedicated to the container, enabling them to collect a large volume of debris over extended periods of use. |

| Industrial vacuum cleaners | These vacuum cleaners are specially designed for specific environments and tasks, such as clean rooms, explosion prevention, dusty environments, or suctioning toner. |

There are also diversifying power sources. Their pros and cons are as outlined below.

| Wall socket powered vacuum cleaners | These vacuum cleaners provide prolonged cleaning with consistent high suction power. Handling the power cable can be cumbersome, except for models with an outdoor exhaust feature. |

| Rechargeable vacuum cleaners | These vacuum cleaners operate on rechargeable batteries, enabling quick cleaning without the hassle of unwinding and rewinding the power cable. They are also convenient for areas without wall sockets. While many are compact enough to be carried in one hand, others are upright or equipped with casters. Due to their limited battery capacity, rechargeable models typically have lower suction power and shorter operating times. The batteries may also degrade after repeated use and need to be replaced with new ones. |

| Engine-powered vacuum cleaners | Some professional wheeled vacuum cleaners are equipped with engines. |

Evolution and history of vacuum cleaners (from the beginning to the 2000s)

The history of vacuum cleaners began in 1868 when Ives W. McGaffey invented a manual vacuum cleaner. This first model used negative pressure to draw in debris. However, its complex manual operation limited its widespread adoption. In 1901, Hubert Cecil Booth invented a vacuum cleaner that operated on electricity. It incorporated a fabric filter for the efficient suction of debris. In 1905, the US-based Chapman and Skinner launched a home electric vacuum cleaner weighing approximately 40 kilograms.

In 1907, James Murray Spangler invented an upright (vertical) vacuum cleaner, further accelerating the appliance’s development. In 1931, upright vacuum cleaners entered the Japanese market but found slow adoption due to the local home environment at the time. After World War II, the widespread use of carpets in the US and Europe boosted the demand for vacuum cleaners. In Japan, the 1960s saw an increase in housing projects with improved home environments, which facilitated the use of vacuum cleaners. Additionally, the growing popularity of carpets drove a rising demand for these appliances.

In the early 1980s, vacuum cleaners that used paper bags for ease of disposal were launched. From the 1990s to 2000s, the mainstream transitioned from canister type vacuum cleaners to cordless stick and cyclone types. From the 2000s onwards, robotic vacuum cleaners and models capable of removing micron-level dust particles were launched. Vacuum cleaner technology has been continually evolving. These advancements indicate the popularization of vacuum cleaners and their transformation from simple cleaning tools to essential home appliances.

| Floor moving type (canister type) | This type has a wide body and is moved by pulling its hose, suitable for cleaning Japanese-style rooms with low furniture. Its low-height design enables easy storage in closets. This type was once popular in Japanese homes. |

| Cylindrical floor moving type (canister type) | This type features an upright cylindrical body and is moved by pulling its hose. It is commonly used in professional models in Japan. |

| Vertical type (upright type) | This type has a tall body with a floor suction port on the bottom and a handle on the top for operation. It can be stored upright. |

| Broom type (stick type) | This type is upright and lightweight. |

| Single-handed portable type (handy type) | This compact type can be carried and operated with one hand. It is often rechargeable (cordless). |

| Over-the-shoulder type (shoulder type) | This type can be worn over the shoulders, making it suitable for cleaning buildings or elevated areas. |

| On-the-back type (backpack type, hip bag type) | This type is used in various vehicles, such as airplanes, trains (passenger cars), and buses. |

| Outdoor exhaust type (central cleaner) | This type involves an outdoor dust collector that connects to sockets in individual rooms, allowing for hose attachment. While it advantageously prevents room pollution with exhaust, it disadvantageously requires costly equipment and installation, and involves carrying a long hose. |

| Wheeled box type | Known also as a sweeper, this type is either manually pushed or operated while mount. It uses an electric motor or engine for dust collection, cleaning, and propulsion. This type is available in dry and wet versions, the latter uses detergents or water. It is suitable for large-scale construction projects and outdoor areas. |

| Robotic type | This robotic version of the wheeled type performs autonomous cleaning. Many of the initial models were designed for professional use. However, since the 2000s, models for home use have also become available. |

Evolution of robotic vacuum cleaners (2000s onwards)

Robotic vacuum cleaners, which have been widely used since the 2000s, are equipped various cutting-edge technologies. They automatically move across floors to draw in debris and dust. While they may not provide a thorough clean, they can remove most house dust, thereby reducing the effort required for cleaning. Some are equipped with advanced technologies, such as distance sensors, AI with learning capabilities, and the ability to link to smartphones.

Further evolution of vacuum cleaners and the importance of lithium-ion batteries

The evolution of battery technologies, particularly rechargeable secondary batteries, has enabled the practical use of cordless and robotic vacuum cleaners. These vacuum cleaners have been significantly facilitated by the invention and widespread adoption of lithium-ion batteries, which are characterized by their light weight and high power output. These batteries possess much larger electrical capacities, enabling longer operating times and broader applications.

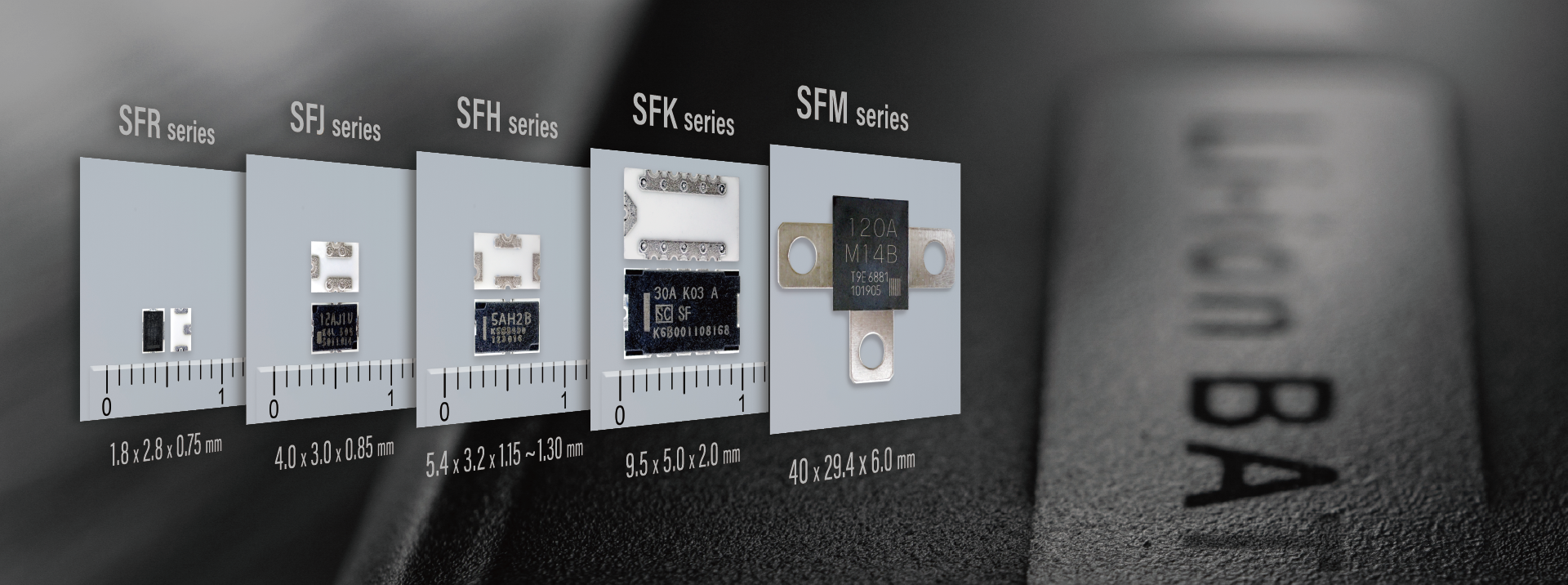

Role of Dexerials’ surface mount type fuse

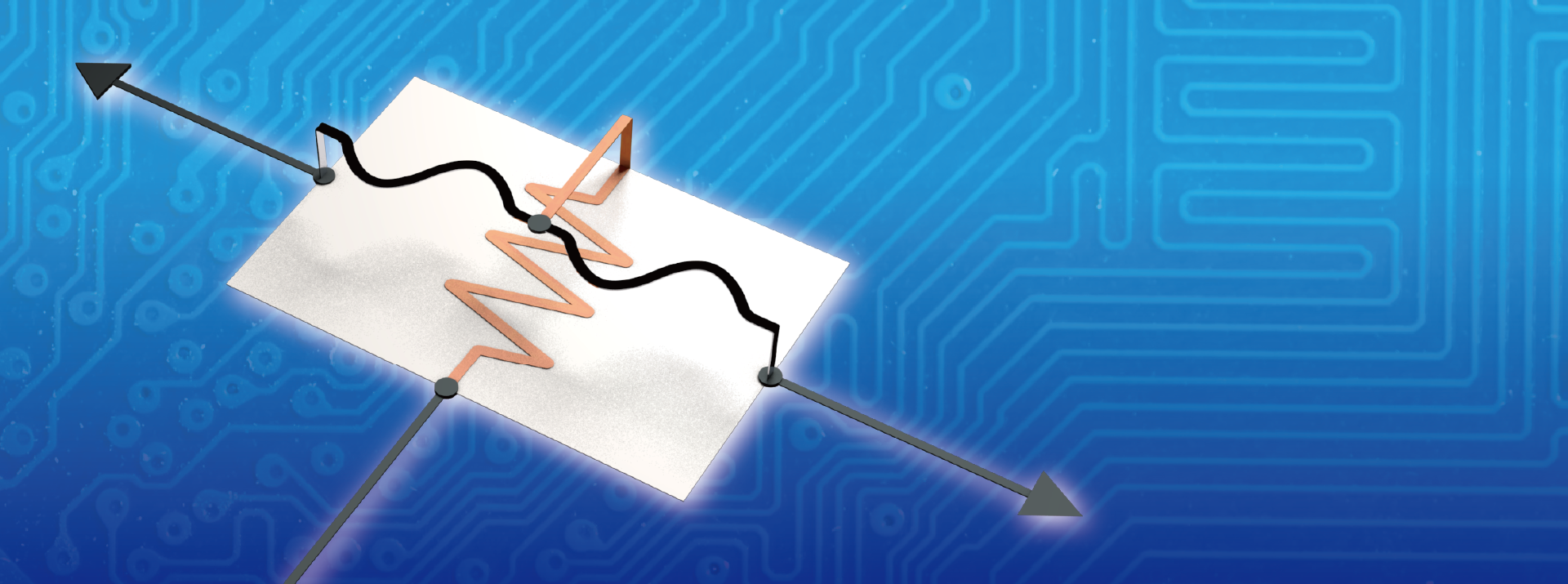

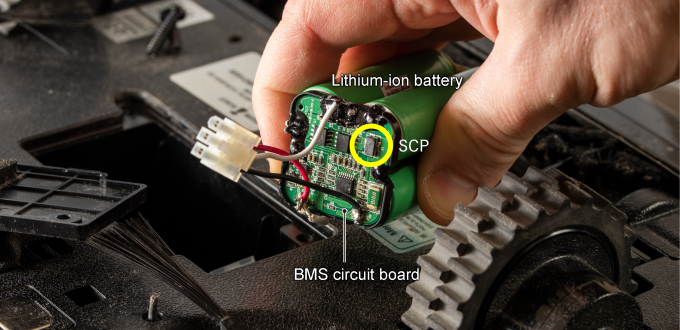

Lithium-ion batteries used in devices such as robotic and stick vacuum cleaners are integrated with Battery Management Systems (BMSs) to ensure battery safety. These BMSs can be protected by incorporating a Self Control Protector (SCP), a surface mount type fuse developed by Dexerials. This fuse ensures safety by shutting off the charging and discharging circuit and isolating the battery from electrical risks in the event of overcharging or overdischarging.

Robotic vacuum cleaners are equipped with built-in lithium-ion batteries and charge on charging docks. Often, they charge and discharge (clean) without human supervision. This means that they can overcharge or overdischarge sometime or somewhere, without being noticed by anyone. Given the large amount of energy they can contain, lithium-ion batteries must have stringent protections in place. One essential protective component is the SCP.

For approximately 30 years, our Self Control Protector (SCP) has served as a reliable secondary protective device for lithium-ion batteries, earning customer trust through its performance and quality.

The SCP is mounted on secondary protection circuits of lithium-ion batteries to ensure the physical, irreversible shutoff of charging and discharging circuits. Its role is to deliberately disconnect and safely disable circuits to prevent the unstable control of charging and discharging in lithium-ion batteries.

Since its commercialization in 1994, our SCP has been recognized as the standard secondary protection fuse for lithium-ion batteries, with over two billion units shipped as of April 2020. (For more details, please refer to the article, “What is ‘SCP’? – Protections of lithium (Li) -ion batteries from errors such as overcharging, overcurrent.”)

The SCP will continue to contribute to the evolution of vacuum cleaners and find broader applications in new battery-powered devices as components become smaller and lighter. Going forward, we will continue to develop this product, helping our customers innovate new products safely and without concerns.

- SHARE

Back to top

Back to top  Contact us

Contact us