- 光学関連

光学弾性樹脂の基本知識

目次

ディスプレイ内の界面反射をなくす光学弾性樹脂

SVRの名称で展開するデクセリアルズの光学弾性樹脂は、光学特性と弾性をあわせ持った樹脂です。主な用途として、スマートフォンやタブレットPCなどのディスプレイのトッププレート(ガラスや樹脂)と、その下にある液晶(LCD)等のモジュールの間にある空間(エアギャップ)に充填する液状接着材料として使われています。

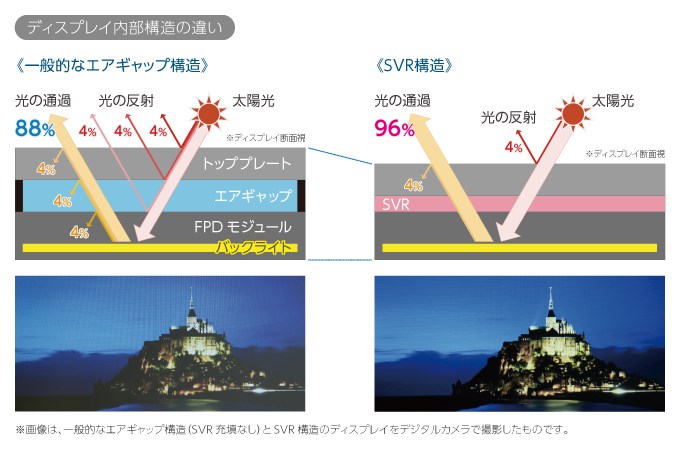

SVRの第一のメリットは、視認性を大きく向上できることです。エアギャップを埋めることで、トッププレート界面での外光の反射と内部の映像光の拡散が最小限に抑えられます。このほか、樹脂自体の弾性により耐衝撃性も強化されることよりスマートフォンやタブレットの薄型化に対応できることから、多数の製品に採用されてきました。

SVRの開発コンセプト

それでは、SVRの原理について見ていきます。例えば、コップの水の中にストローをいれると、空気と水の界面でストローがわずかに折れているように見えます。これは空気と水の光の屈折率の違いが原因です。

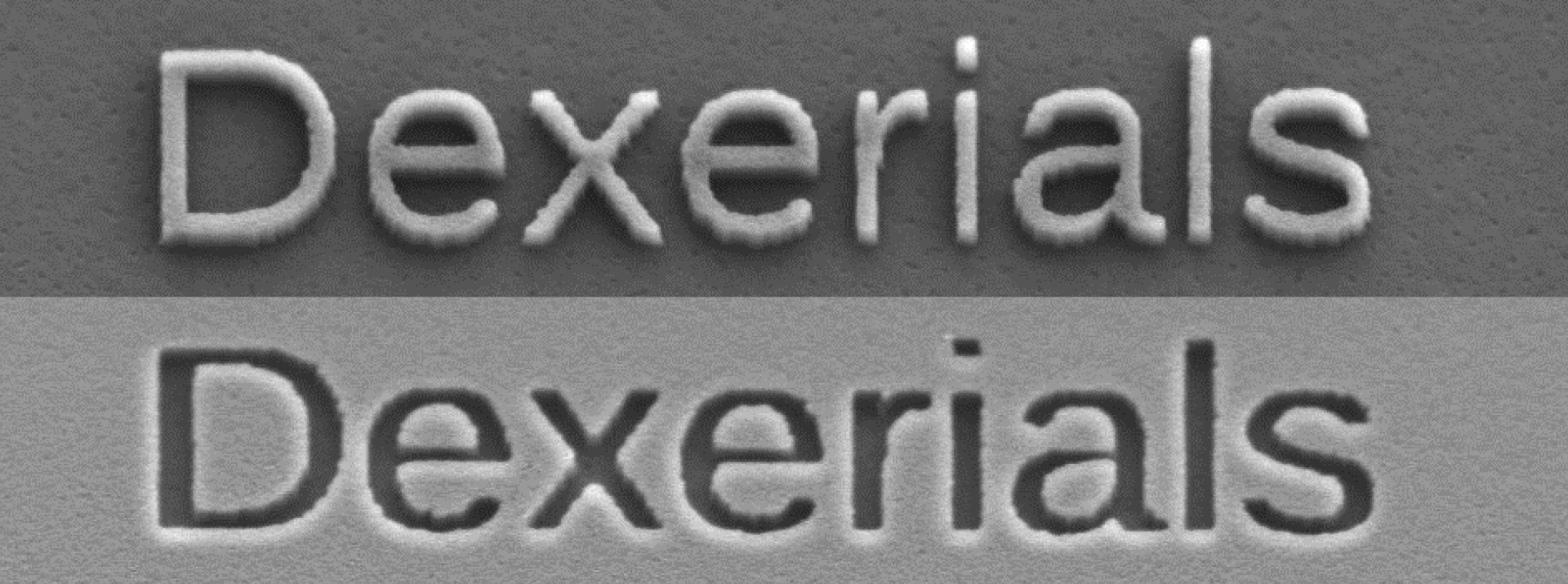

以前の携帯電話では、外光が入ってきたときにトッププレートとエアギャップ内の空気との屈折率の違いからディスプレイの視認性が悪くなる現象がで起こっていました。それに対してトッププレート(ガラスまたは樹脂)と同じ屈折率にしたSVRをエアギャップに充填することで、屈折が起こる箇所がなくなるため、外光はそのままLCDに到達します。これによりエアギャップが残る構造では約12%あった明るさとコントラストのロスを、SVRを充填した構造は理論上約4%まで抑制することができ、視認性を向上させることが可能となりました。

スマートフォンやタブレットPCから車載ディスプレイなど多様な機器に採用

デクセリアルズでは2007年からSVRの販売を開始しています。デクセリアルズのSVRは多くのスマートフォンやタブレットPC、液晶テレビなどに採用されています。

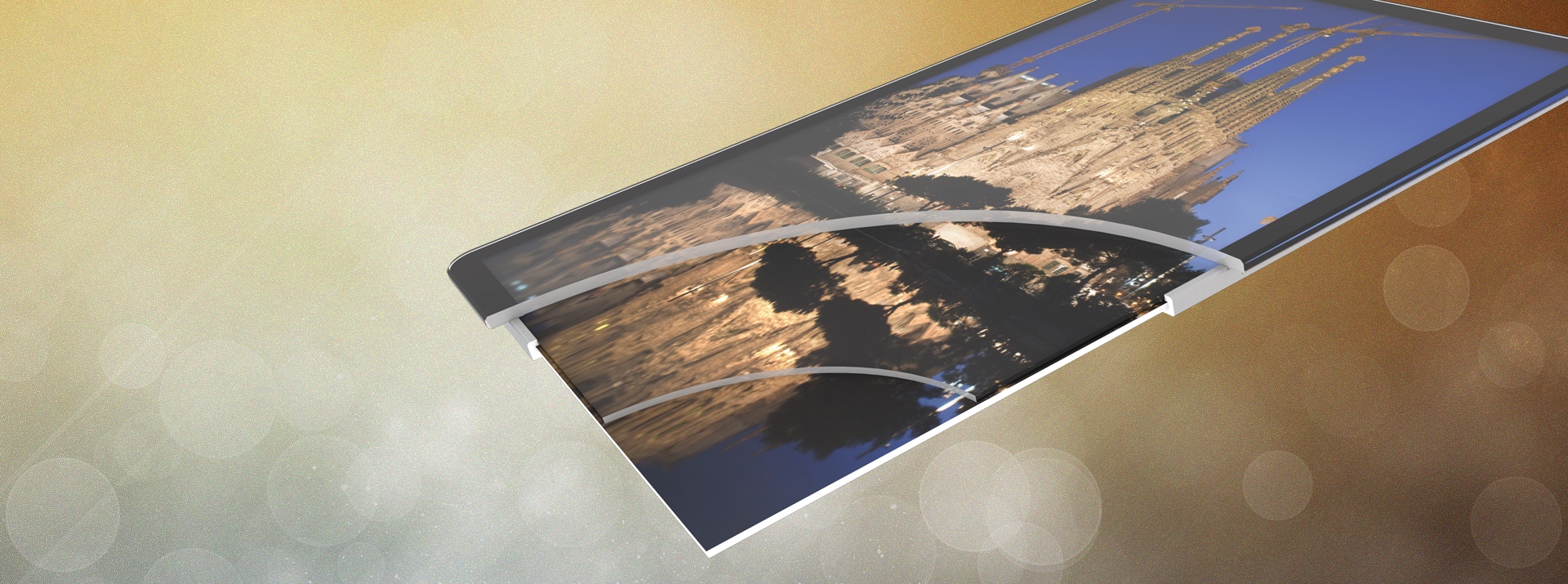

また、最近になってSVRの用途として増えているのが、自動車用途です。特に、車載ディスプレイのデザイン多様化により曲面形状の2.5Dもしくは3Dのトッププレートが使用される機会が増え、平面形状のフィルムタイプの光学粘着フィルム(OCA/LOCA)ではそうした曲面を貼合することが難しいケースもあります。その点、液状のSVRは「かまぼこ」のような形状をしたトッププレートとディスプレイ間のエアギャップも隙間なく埋めることができることから、自動車メーカーやTier1と呼ばれる部品メーカーに採用されるケースが増加しているのです。

SVR開発の背景とスマートフォンにもたらしたメリット

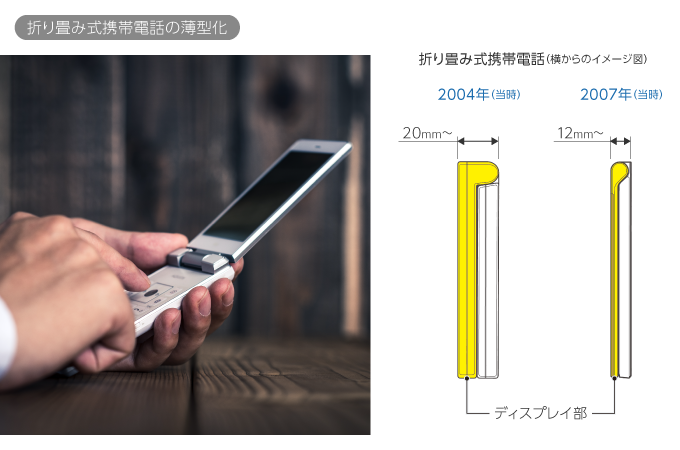

SVRの開発は「ガラケー」と呼ばれていた携帯電話の薄型化、軽量化のニーズが高まりに始まり、2007年に上市されました。下記のイラストにあるように、2004年当時の折りたたみ式携帯電話の厚みは20mmを超えるものが主流でした。しかしガラケーは日本独自の進化をとげ、2007年には薄いもので12mm前後まで薄型化が進みました。

ガラケーが年に数回のペースで新製品発表がされていた当時、携帯電話をより薄く、より軽量に、かつ大型の画面を搭載したいというニーズはとどまることを知らず、これに貢献することができる素材としてSVRは格好の製品となりました。

一方で、携帯電話の筐体を薄くすると、衝撃や折り曲げの力に対してどうしても弱くなります。しかし、ディスプレイ部のエアギャップを樹脂のSVRで埋めることによって、「薄さ」と「ディスプレイ部の剛性向上」という相反するニーズも満たすことができました。また、SVRによって光の反射が低減したことで、LCDの輝度とコントラストも向上し画面の視認性が良くなり、さらにより少ない電力で同じ明るさの画面を表示できることから、電池の持続時間向上にもつながったのです。

関連記事

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら