- 光学関連

無機波長板の機能と特長-薄膜プロセス加工技術から生まれた光学デバイス

光の振動方向を回転させる波長板の機能

「波長板」は、光の利用効率を上げることを主な目的に使用される光学デバイスです。プロジェクターなどの光学精密機器の内部で、光の振動方向を任意の方向に「変換」させています。以下にその構造と働きについて、詳しく見ていきましょう。

こちらで解説した偏光板は、無偏光の状態の光から、特定の振動方向光だけを透過させる機能を持っていますが、これに対して波長板は、入ってくる光の位相(光の振動するタイミング)をずらして、偏光の状態を変化させることができます。

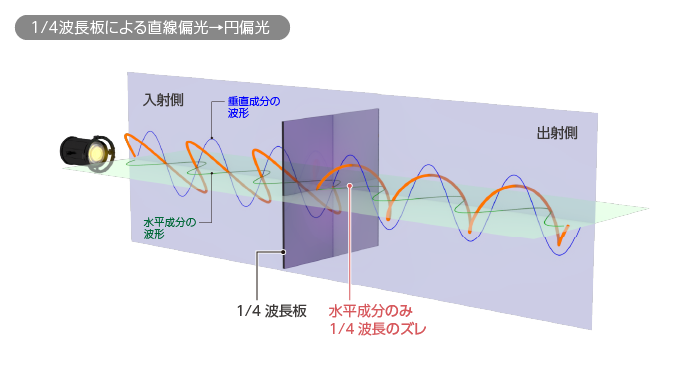

下記2つのイラストは、いくつか種類がある波長板の中でも、光学デバイスとして使用される機会の多い「1/2波長板」と、「1/4波長板」から得られる光を示した図です。

光は2方向の直行する光のベクトルを合成したものとみなすことができます。下記のイラストのように位相を1/2波長ずらした場合は、ずらさなかったときに対して90度の角度がついた直線偏光を得ることができます。

一方、下のイラストは位相のタイミングを4分の1ずらす1/4波長板から出力される光の模式図です。合成された光のベクトルが螺旋状に弧を描くことから、「円偏光」と呼ばれます。1/4波長板は、逆に円偏光の光を入力すると、直線偏光の光を出力することができます。

波長板によって光を効率よく利用

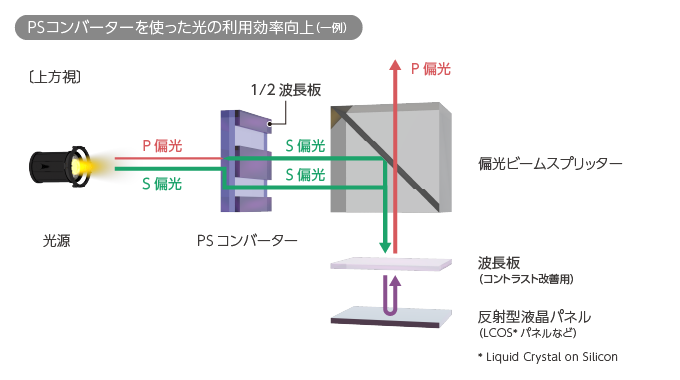

次に、実際に波長板が機器の中のどのような場所に使われているかを例示します。波長板が使用されている機器の一つに、会議などで利用されるプロジェクターがあり、その内部にあるPSコンバーターという光学部品に組み込まれています。光源から放たれた光は、PSコンバーターによって偏光変換され、液晶にマッチした偏光に揃えることで光利用効率が高められるものです。

下記のイラストは、光源の光がPSコンバーターを通ったあと、プロジェクター内部でどのような経路をたどって画像を投影しているかを示しています。左側の光源が発する無偏光の光は、P偏光(横方向に振動している光)とS偏光(縦方向に振動している光)が混ざり合った状態です。PSコンバーター(偏光変換素子)は、S偏光はそのまま透過しますが、P偏光は1/2波長板を通過しS偏光に変換して透過します。つまり、無偏光の光を、S偏光の光に変えるのがPSコンバーター(1/2波長板)の役割です。PSコンバーターを透過したS偏光は、偏光ビームスプリッターで反射したあと、反射型液晶パネルに入射し、画像を出力する画素のみP偏光へと変化して、偏光ビームスプリッターを透過し画像が投影されます。

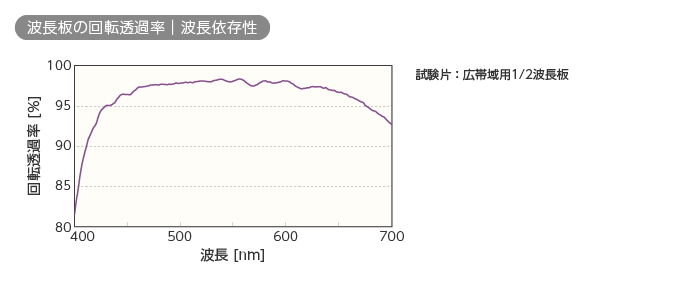

波長板に求められる第一の性能は、「回転透過率」が高いことです。回転透過率とは、波長板に入射した光が、どれぐらいの効率で偏光変換されたかを示す割合を指します。下記は、デクセリアルズの開発した広帯域1/2波長板の偏光透過率を示す2種類のグラフです。上が波長を横軸にとったグラフで、下は光の入射角を横軸にとっています。光源の光をできる限り有効に使うためには、なるべく広い波長帯域、入射角で100%に近い偏光透過率を保つことが求められます。

デクセリアルズの無機波長板の特長

従来の波長板の多くは、有機材料で作られていました。有機材料はコストが安いというメリットがありますが、熱に弱いという大きな欠点があります。そのため、近年の高輝度化が進んでいるプロジェクターでは長期間使用に耐えうる無機材料の波長板が使用されるようになっています。

これに対して、デクセリアルズの開発した無機波長板の特長は、大きく次の3つが挙げられます。

- 無機材料であるため、耐熱・耐光性に優れている。

- 薄膜プロセスでの製造により、お客さまのニーズに合わせた小さな位相差の膜を設計することができる。

- 薄膜プロセスでの製造により、入射角度依存性が少ない位相差板の製作ができる。

また無機波長板には水晶を材料とするものもありますが、水晶製の波長板は機械による研磨加工で1/2や1/4の位相差を実現することから、精度を出しにくいという欠点があります。

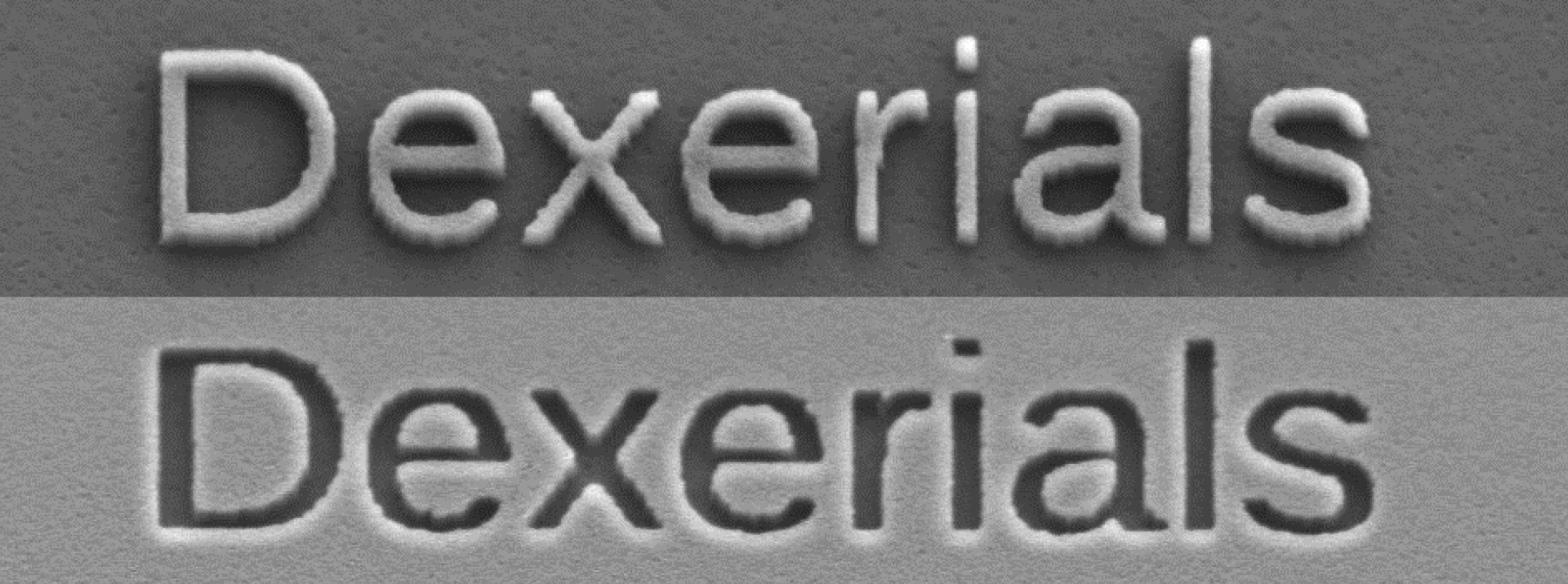

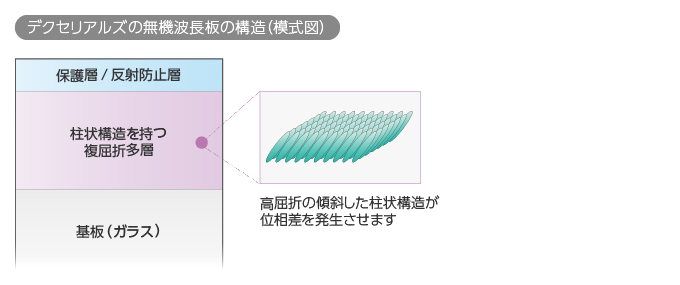

これに対して、デクセリアルズの開発した薄膜プロセスによる波長板は、無機材料をガラス基材の上に斜方蒸着することによって、柱状構造体を形成し、位相差を発現します。それにより、高い精度で製造することが可能となっています。

より明るく、高画質な映像を投影できるプロジェクターの性能向上の実現に向けて、これからもデクセリアルズは研究を進めてまいります。

関連記事

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら