- 光学関連

無機拡散板の機能と特長-ガラス基板上にマイクロレンズを直接形成した光拡散素子

プロジェクターなど、レーザー光を広げる拡散板の機能

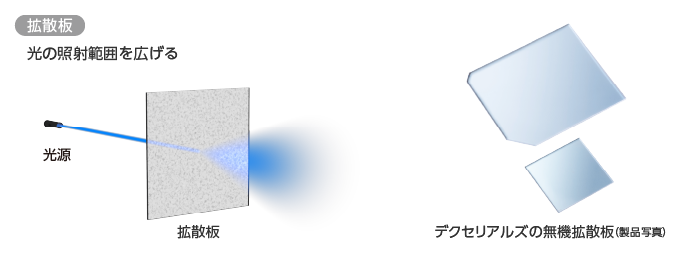

デクセリアルズが販売する「無機拡散板」は、主な用途として、プロジェクターのレーザー光源の光を拡散する素子として使われています。まずは、その背景を見ていきましょう。

壁面に光で映像を映し出すことができるプロジェクターは、会議などのビジネスシーンや、エンターテイメント分野での活用が広がり続けています。近年そのプロジェクターに起こった大きな技術革新の一つが、「水銀ランプからレーザー光に、光源が変化したこと」です。アーク放電によって強い光を発することのできる水銀ランプは、プロジェクターの光源として長年利用されてきました。しかし、世界的な環境問題への意識の高まりから水銀に対する規制が強まったことで、最近では多くのメーカーが水銀ランプを用いたプロジェクターの生産を減らしています。

代わってプロジェクターの光源として利用が進んでいるのが、レーザーです。レーザー光は、レーザーポインターを見ればわかるように、指向性が強く、そのままではほとんど広がりません。自然に四方へ広がる水銀ランプの光とは性質がまったく違うため、プロジェクターの光源に使用するには、光を拡散する必要があるのです。

そのために用いられるのが、当社製品をはじめとする「拡散板」です。拡散板に入射したレーザー光は、あらかじめ設計された拡散角度に従って広げられ、出射されます。拡散板には有機材料で製造された製品もありますが、プロジェクター用の拡散板はレーザー光による発熱に長期間耐える必要があることから、熱に強い無機拡散板が多くの場合使用されています。

無機拡散板の原理と機能

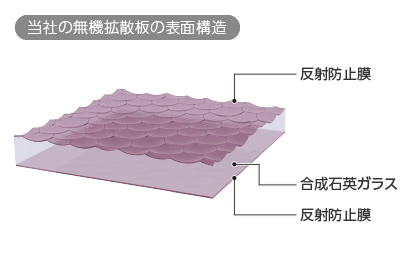

下のイラストは、当社が開発した無機拡散板の表面を模式的に拡大したものになります。「マイクロレンズ」と呼ばれる極微細なレンズが多数並んだ構造をとることによって、入ってきたレーザー光が拡散されます。

こうしたミクロンオーダーのレンズが配列された構造を「マイクロレンズアレイ」と呼びますが、当社の拡散板の特徴は、一つ一つのレンズの大きさや配置などカスタム対応が可能です。

一般的なマイクロレンズアレイは、整然と同じ大きさ、形のレンズが近距離で配置されており、この場合、拡散した光が一定の周期で強め合う現象が発生し、輝度分布を悪化させます。

それに対してデクセリアルズでは、微細加工技術を応用して、レンズ形状や配列を任意に設定することができ、周期的に光が重なり合うことなく、全体的に明るさが均一となるレンズ形成を可能にしています。

トップハット配光構造で角度と形状もカスタマイズできる無機拡散板

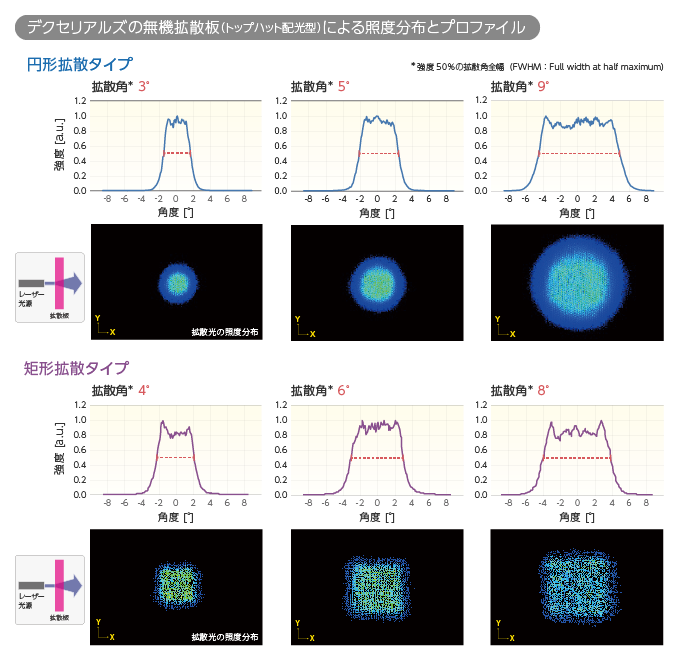

デクセリアルズ製の無機拡散板のもう一つの大きな特長が、「トップハット配光構造」と我々が呼ぶものです。下記は、従来品と最新のトップハット配光型拡散板の違いを、拡散光のプロファイルで示したグラフになります。

ひと目でおわかりになる通り、従来のガウシアン配光型の拡散板は、真中は明るいですが周辺にいくに従って薄暗くなっていくのに対し、トップハット配光型拡散板は全体にわたって明るさが均一に広がっています。拡散角度による明るさを示したグラフで、配光分布が帽子(ハット)のような形を示すことから「トップハット」と名付けられました。

このトップハット状の配光を実現したのが、デクセリアルズの持つ微細構造の製造技術です。下記は、当社がラインアップするさまざまな拡散板の照度とプロファイルを示しています。お客さまのニーズに合わせた拡散板をご用意しています。

こうした幅広いラインナップの拡散板をご用意しているのは、お客さまにとっての設計自由度を向上することが目的です。画質の向上にも直結する、最適な拡散板の選択をデクセリアルズはサポートしています。

関連記事

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら