- Optical Products

Moth-Eye Structures: The Ultimate Anti-Reflection Technology

Contents hide

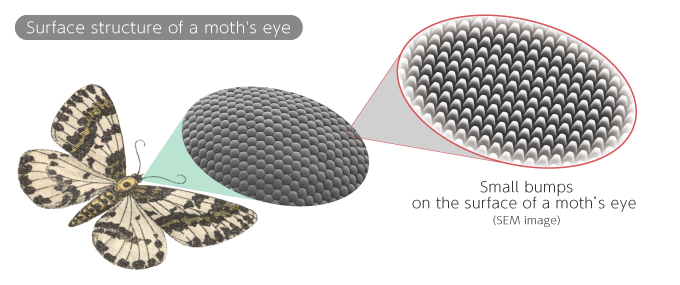

The secret to anti-glare capabilities of moth’s eyes

Moths, being nocturnal insects, possess a unique eye structure that allows them to navigate freely at night, aiding them in finding food and evading predators. The surface of a moth’s eye is covered with numerous nano-level microscopic bumps arranged uniformly, enabling it to absorb minimal light without reflecting it.

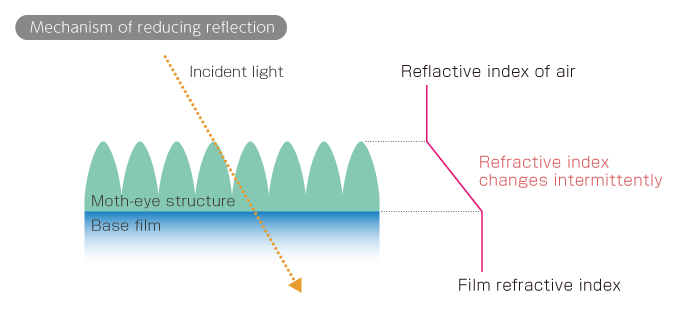

These bumps are uniformly arranged in rows smaller than the wavelength of visible light. Light reflection occurs due to the difference in refractive indices between air and the material the light strikes. However, the bumps on a moth’s eye are curved and spindle-shaped. This shape allows light from various angles to enter the eye while continuously altering the refractive index, resulting in almost no light reflection.

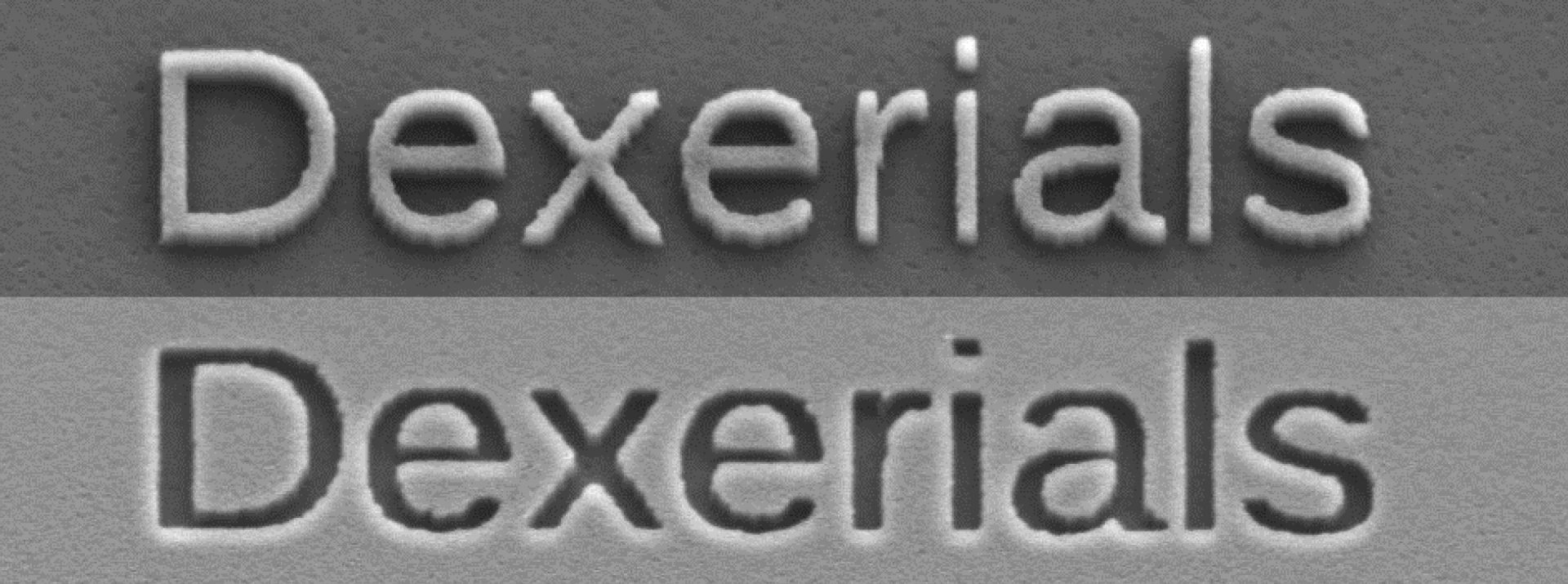

Dexerials’ original manufacturing method for Moth-eye type anti-reflection film

Dexerials’ moth-eye type anti-reflection film nearly matches the reflection-blocking capability of a moth’s eyes by forming resin bumps smaller than the wavelength of visible light (380 to 780 nm) on the film.

A method known as “anodic oxidation” is commonly used to form moth-eye structures, where a porous structure is created through the chemical treatment of aluminum sheets. However, this method restricts the shape and size of the bumps to certain specifications.

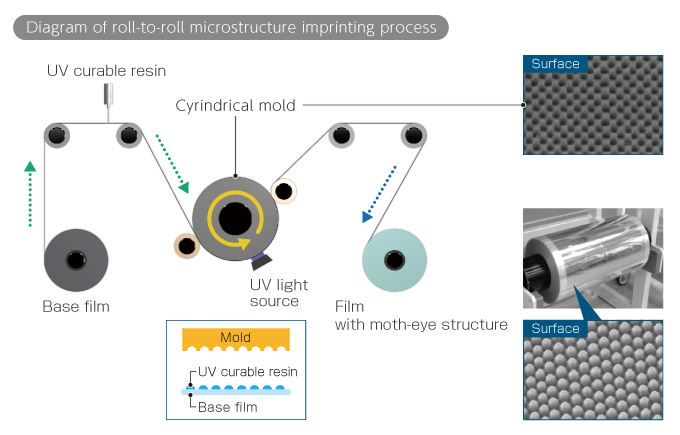

In contrast, Dexerials’ method of creating moth-eye structures employs the same technology used in Blu-ray discs and semiconductors. In this method, holes (pits), which form the foundation of moth-eye structures, are initially created on a rolled master disc using laser lithography technology. Subsequently, the formed pits are transferred to the film using a method called nanoimprinting. The irradiation angle and position of the laser beam are precisely controlled by a computer, enabling control of the microstructure patterns.

The unique manufacturing process developed by Dexerials is explained in detail in the Tech Times article, "How an Anti-reflection with such high transparency that you hardly notice it's there -New technology for forming microstructures -".

Achieving complete transparency

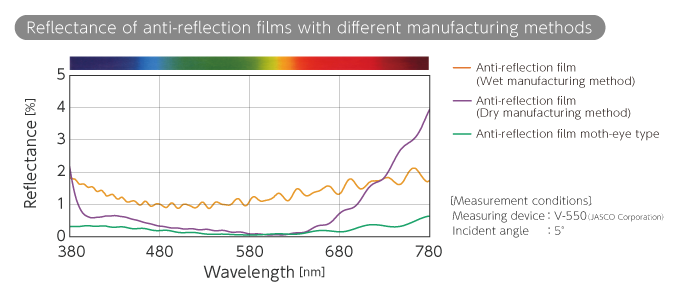

The graph below illustrates the reflectance of moth-eye (microstructure transfer) anti-reflection film (green line) and conventional manufacturing methods (dry manufacturing method using sputtering = purple line, wet manufacturing method using solvent coating and drying = orange line). Anti-reflection films other than the moth-eye type reduce reflectance by overlapping thin films with different refractive indices, causing light waves to interfere with each other. In contrast, the reflectance of moth-eye type film is lower in most wavelength ranges. Therefore, a significant advantage of moth-eye type anti-reflection film is that the reflectance does not vary depending on the wavelength, and can achieve anti-reflectance over the entire visible light range.

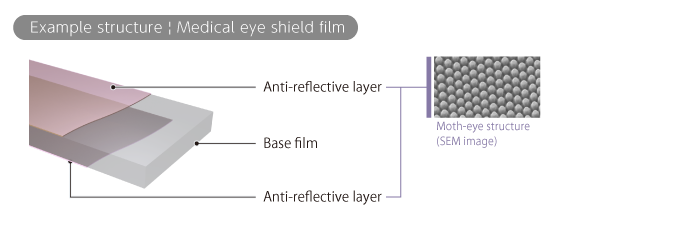

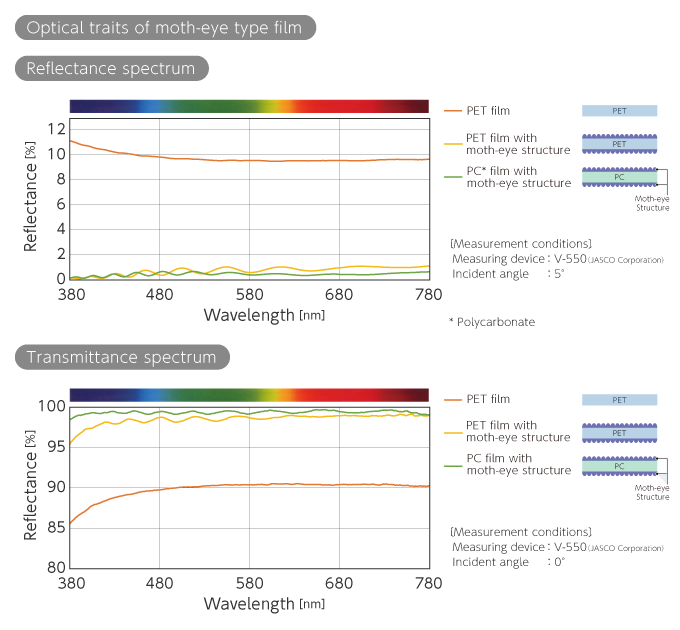

Next, the graphs below display the total light transmittance and reflectance of PET film and moth-eye type film. The transmittance of PET is 89%, while that of moth-eye type film is 99%. Additionally, the reflectance of PET is around 10%, while that of moth-eye type film is only between 0 to 1%. Currently, the majority of face and eye shields used in hospitals and food factories utilize PET film. However, replacing these films with moth-eye type films can significantly enhance transparency while reducing glare.

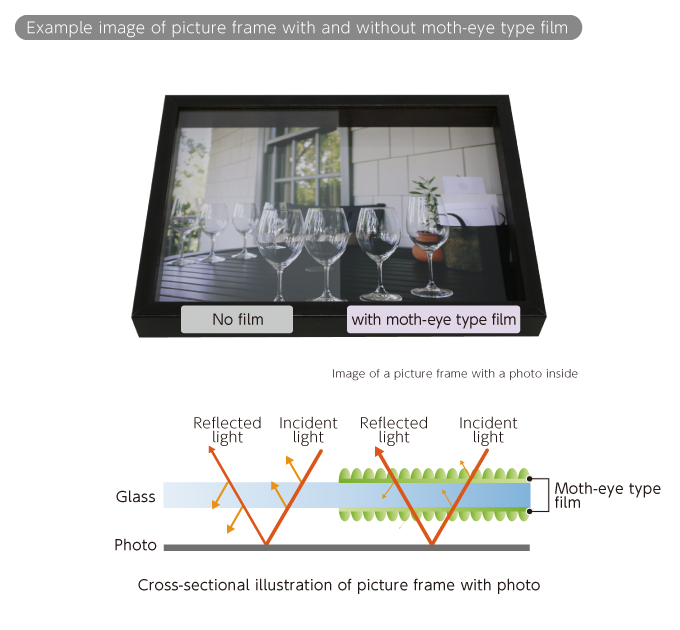

The following image demonstrates the effectiveness of moth-eye type film in preventing reflections. Since the left side appears somewhat white, one might assume that the film is applied on the left side. However, as shown in the cross-sectional image, the moth-eye anti-reflection film is applied on the front and back of the right half of the glass.

Improved functionality with anti-fogging properties

Another notable feature of Dexerials’ moth-eye type anti-reflection film is its anti-fogging properties. Medical shields necessitate clear vision and minimal fogging to avoid impacting diagnoses and treatments. Fogging on medical shields occurs when water vapor from exhaled air adheres to the shield’s surface and condenses into small water droplets. Dexerials’ film, with its microstructure formed from a highly hydrophilic resin, prevents condensation by instantly spreading any adhering water vapor droplets across the surface.

Be careful not to scratch moth-eye type film

As previously mentioned, Dexerials’ moth-eye type anti-reflection film prevents glare and provides high transparency. However, it’s important to note a few things. Firstly, it tends to get dirty relatively easily. Fingerprints and other smudges on the surface of the moth-eye type film become noticeable due to its extremely high transparency, which wouldn’t be an issue with ordinary film. Additionally, it’s challenging to remove dirt if substances like sebum come into contact with the film due to its nano-level microstructure.

Nevertheless, such stains can be removed by wiping with a cloth or cotton swab dampened with water and detergent. Scrubbing the surface with a hard object, such as steel wool, will scrape off the fine irregularities, thereby damaging the moth-eye structure. Therefore, users should exercise caution when cleaning the product to avoid applying excessive force that could damage the surface.

In recent years, moth-eye type anti-reflection films have found use in a variety of applications, including medical shields, art exhibits, and electronic products like TVs and camera lenses. Dexerials will continue to explore further possibilities of this nature-inspired technology to meet diverse customer needs.

Related articles

- SHARE

We provide materials on our products and manufacturing technologies.

Feel free to download it for free.

Download Materials

We provide materials on our products and manufacturing technologies.

Feel free to download it for free.

Download Materials