- Optical Products

Quantitative Evaluation Method for Fingerprint Cleanability on Automotive Displays — Evaluation Criteria Applicable to RFQs —

In recent years, automotive displays have continued to increase in size and brightness. As a result, fingerprints remaining on display surfaces have become a noticeable issue, as they affect both visibility and perceived premium quality. In particular, fingerprints alter reflected light and color appearance on the display surface, which can degrade visual performance.

Against this background, there has been growing demand for a method to quantitatively evaluate fingerprint cleanability—how closely a display surface can return to its original appearance after fingerprints are cleaned. However, conventional evaluation approaches have faced challenges in achieving stable and reproducible results due to variability in fingerprint application and cleaning conditions.

Dexerials has established an evaluation method that quantitatively assesses the difference between a surface after fingerprint cleaning and a fingerprint-free state using optical properties such as reflectance and color difference (ΔE*ab). This article introduces the key points of this evaluation method, as well as the evaluation conditions established through discussions with automotive OEMs.

目次

- 1.Challenges in Evaluating Fingerprint Cleanability — Issues Identified in Automotive Display Development —

- 2.Fingerprint Cleanability Evaluation Method Established by Dexerials

- 3.Components of the Evaluation Method (Fingerprint Application, Cleaning, and Optical Evaluation)

- 4.Evaluation Criteria Co-Created with OEMs and Applicability to RFQs

- 5.Background to the Establishment of the Evaluation Method

- 6.Detailed Documentation for Fingerprint Cleanability Evaluation

Challenges in Evaluating Fingerprint Cleanability — Issues Identified in Automotive Display Development —

One of the main challenges in evaluating fingerprint cleanability has been ensuring reproducibility in fingerprint application. Human fingers differ in softness and sebum content, making it difficult to apply fingerprints uniformly on display surfaces, even when artificial reproduction is attempted. This variability directly affects measurement results. Cleaning conditions also introduce uncertainty. Differences in cleaning cloths, applied load, and the number of cleaning passes can lead to inconsistent evaluation outcomes. In addition, optical measurement itself can become unstable if the fingerprinted area does not sufficiently cover the measurement aperture, resulting in variations in reflectance and ΔE*ab values.

Toyoshima, General Manager of Product Development, Automotive Solutions Business Unit at Dexerials Corporation, describes the situation as follows:

“Without a way to reproduce fingerprints uniformly, it was difficult to compare cleanability after cleaning. Establishing a reliable evaluation foundation was the most challenging part.”

Fingerprint Cleanability Evaluation Method Established by Dexerials

Through repeated discussions with automotive OEMs (original equipment manufacturers), Dexerials systematized fingerprint application, cleaning procedures, and measurement conditions into a single evaluation framework. This method enables consistent evaluation of fingerprint cleanability not only at the initial stage but also after reliability testing.

The key feature of this evaluation method is the shift from conventional qualitative visual checks to quantitative evaluation. By combining optical properties such as reflectance and ΔE*ab with contact angle as an indicator of surface condition, the method achieves high reproducibility even with a limited number of test samples.

Components of the Evaluation Method (Fingerprint Application, Cleaning, and Optical Evaluation)

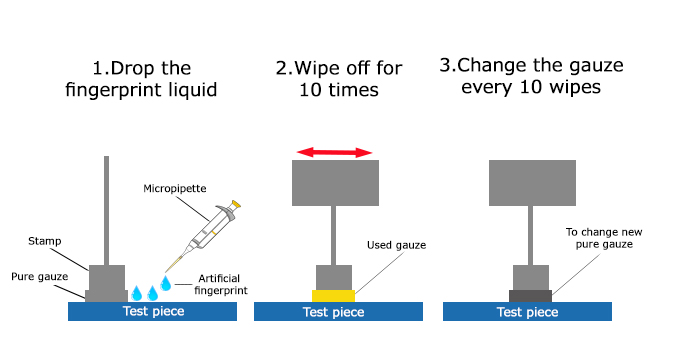

Reproducible Fingerprint Application

An artificial fingerprint solution that simulates sebum is dispensed in a specified amount and uniformly spread across the evaluation area. On highly anti-smudge surfaces such as anti-reflection film (ARF), water alone does not adequately wet the surface, making it difficult to form a uniform fingerprint layer. For this reason, the composition of the artificial fingerprint solution, the dispensing volume, and the spreading procedure were optimized to ensure sufficient uniformity for evaluation. During the early stages of method development, a finger-shaped actuator was tested to apply the solution. However, this approach was found to be unsuitable for achieving uniform coverage. As a result, a method using gauze and a dedicated jig was adopted to spread the solution into a thin, uniform film on the display surface.

Standardization of Cleaning Conditions

Cleaning conditions are defined in terms of cloth type, applied load, number of cleaning passes, and starting position. Initial cleaning passes, which can cause instability in measurement values, are excluded from evaluation. The same cleaning conditions are applied again after reliability testing to assess changes in fingerprint cleanability resulting from long-term use.

Stabilized Optical and Surface Evaluation

Fingerprint residue after cleaning is quantified using reflectance and ΔE*ab. To reduce measurement variability, fingerprints are applied so that the measurement aperture is fully covered, minimizing the influence of positional misalignment or uneven application. This approach stabilizes reflectance and ΔE*ab values and enables quantitative comparison of fingerprint cleanability. In addition, by measuring contact angle both before and after reliability testing, it becomes possible to comprehensively assess fingerprint cleanability by combining visual appearance with an indicator of surface wettability.

Evaluation Criteria Co-Created with OEMs and Applicability to RFQs

This evaluation method was established by defining evaluation conditions through discussions with automotive OEMs. Agreement has been reached on cleaning cloths, applied load, number of cleaning passes, environmental testing, and rubbing tests. Integration of this evaluation method into Request for Quotation (RFQ) documents—where product specifications and evaluation requirements are defined—is currently being considered, and further standardization is expected. Recommended conditions for inclusion in RFQs are summarized in the downloadable material.

Background to the Establishment of the Evaluation Method

As a materials manufacturer, Dexerials has long been engaged in the development of optical materials such as anti-reflection film (ARF). By leveraging expertise in optical evaluation accumulated through this work, along with extensive measurement capabilities, Dexerials was able to verify each element of the evaluation method, from fingerprint uniformity to optimization of optical and surface measurement conditions.

Detailed Documentation for Fingerprint Cleanability Evaluation

This evaluation method is currently being applied in projects intended for OEM adoption and is expected to become a standard RFQ evaluation criterion in the future.

The detailed documentation for the “Fingerprint Cleanability Evaluation Method” includes fingerprint application conditions, cleaning test procedures, recommended optical evaluation conditions (reflectance and ΔE*ab), evaluation flow using contact angle, and examples of how these criteria can be referenced in RFQs.

[Download Material]

The material compiles information required for reviewing evaluation criteria and forming internal consensus, and can be directly applied in practical development activities.

It can also serve as reference information when engaging in technical discussions with OEMs.

関連記事

- SHARE

We provide materials on our products and manufacturing technologies.

Feel free to download it for free.

Download Materials

We provide materials on our products and manufacturing technologies.

Feel free to download it for free.

Download Materials