- 光学関連

光学弾性樹脂の優れた物性と特長

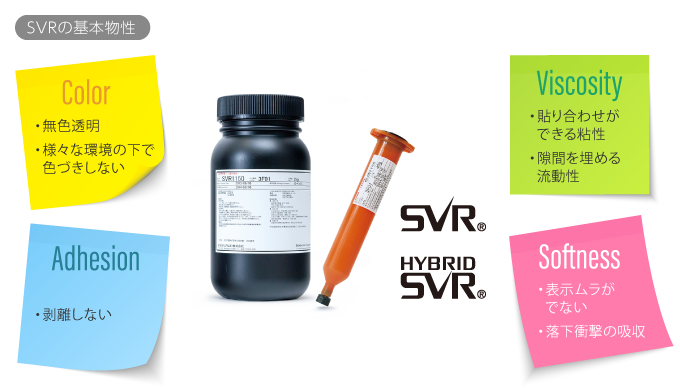

光学弾性樹脂(OCR)に求められる基本的な物性

当社が開発、製造、販売する光学弾性樹脂(SVR)は、スマートフォンなどのディスプレイ部のトッププレートと液晶モジュールの間を埋めて接着しながら、光学的な特性によって液晶ディスプレイ(LCD)画面の視認性を向上させるとともに、耐衝撃性を高める光学弾性樹脂(OCR)です。その機能を十分に発揮するためには、複数の特性が必要となります。

まず、第一に求められるのが「UV硬化後も無色透明で、使用にともなうさまざまな環境下でも色づきしないこと」です。画像の視認性向上のために使われるSVRが、太陽光による樹脂の劣化等で色がついてしまっては、本末転倒です。またSVRはトッププレートとLCDを接着する接着剤としての機能が基本であるため、接着後に剥離しないことも重要です。

また、SVRの貼合工程では、液状のSVRが部品の間を隙間なく埋めるための適度な流動性をもっている必要もあります。さらにUV硬化後の収縮が原因となる表示ムラを防ぐとともに、スマートフォンに衝撃が加わったときの力を吸収する樹脂の柔軟性も求められます。当社のSVRはすべて、上記に述べた各種の条件を厳格な評価のもとクリアしています。

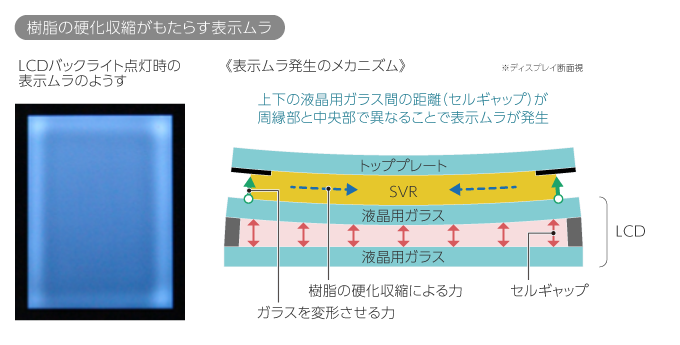

樹脂硬化によって起こる液晶の表示ムラとその対策

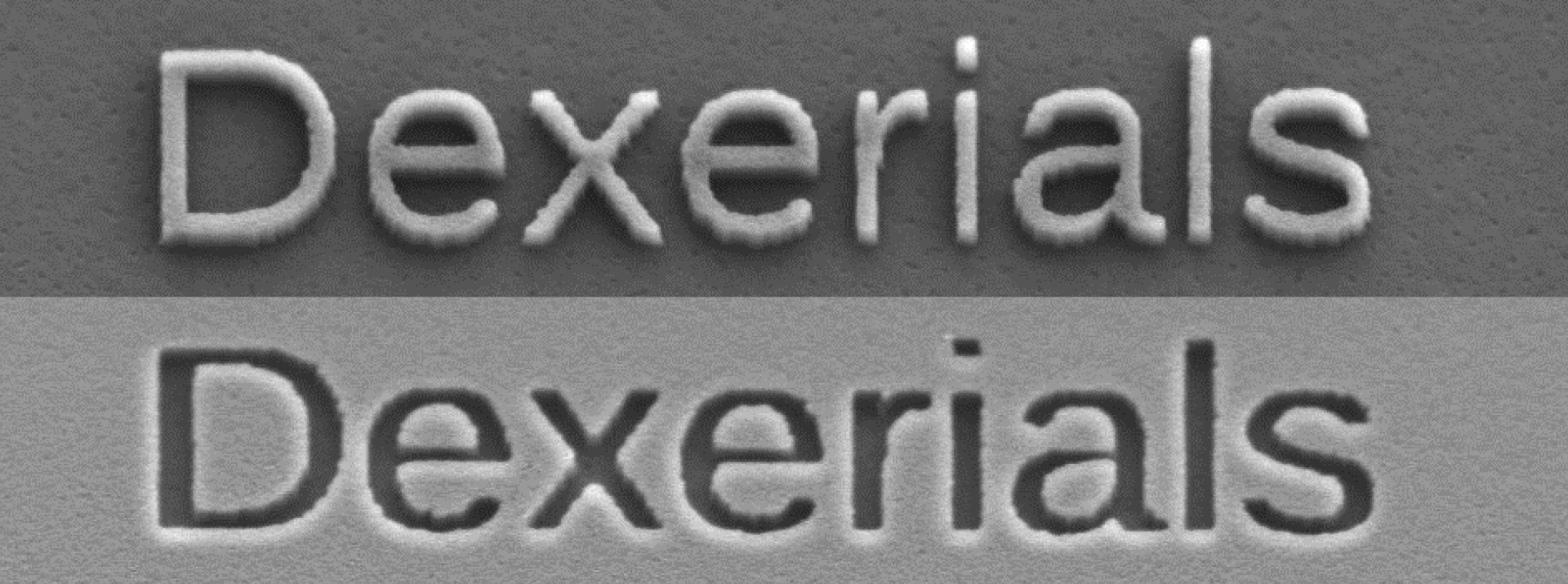

光学弾性樹脂(SVR)の樹脂の柔軟性が十分に保持されていなかった場合、表示ムラが発生する可能性があります。下記左の写真は、2000年代初頭の携帯電話に使われていた液晶に、樹脂の硬化収縮による表示ムラを意図して発生させたテストの結果です。写真では周辺部が四角く白くなっていることが確認できます。この表示ムラは樹脂が硬化にともなって収縮し、接着されているLCDを画面の中心方向に引っ張って、平らだった部材の一部が変形することで起きています。樹脂自体の硬化収縮率が低く十分な柔軟性があれば、収縮しても液晶の配向を変えるほどの応力は発生せず、表示ムラを抑えることができます。

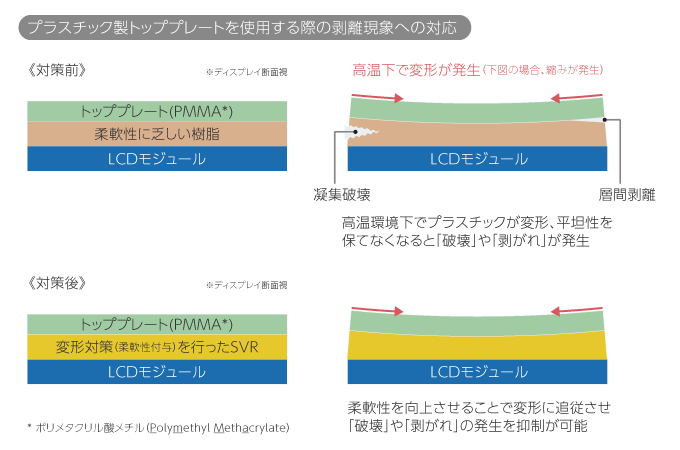

プレートの反りに追随して剥離を防ぐ柔軟性

光学弾性樹脂(SVR)は近年、自動車の車載ディスプレイに採用される機会が増加していますが、その際にもSVRの柔軟性が求められるケースがあります。近年のスマートフォンのディスプレイはトッププレートにガラスを使用することがほとんどですが、車載ディスプレイは衝突事故などが起こった際にガラスの飛散を防ぐため、多くはプラスチックのトッププレートが採用されています。しかしプラスチックは湿度や温度の影響を受けて大きく反りやすくなるため、その反りの力にも耐えられる樹脂設計がSVRに必要となるのです。対策としてはSVRの樹脂の「柔軟性」を向上させ、接着したトッププレートが反って形状が変化しても、樹脂が伸びて追従することで剥離を防ぐアプローチが有効です。

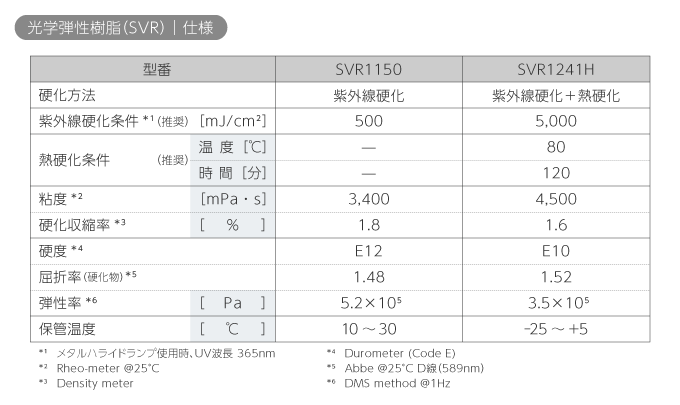

特性を決める光学弾性樹脂(SVR)の構成素材

このような特長を実現するために重要となるのが光学弾性樹脂(SVR)の組成です。SVRはUVアクリル樹脂で構成されています。それら材料の選択と適正な分量のコントロールによって、粘度、硬度、硬化反応の速さ、信頼性、硬化収縮の割合、屈折率、弾性率などのパラメーターを、お客さまが求めるスペックに合わせてカスタマイズします。下記に一例として、モバイル機器や車載用ディスプレイに搭載されるデクセリアルズの中・小型フラットパネルディスプレイ向けSVR2種類のスペック表を示しました。このほかにもデクセリアルズでは大型テレビや大型サイネージディスプレイの薄型化、高コントラスト化に有効な製品なども用意しており、SVRの多数の「レシピ」によってお客さまのさまざまなニーズに応えています。

関連記事

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら