- 光学関連

ロールtoロール方式のスパッタ技術を使った反射防止フィルム

反射防止フィルムのしくみ

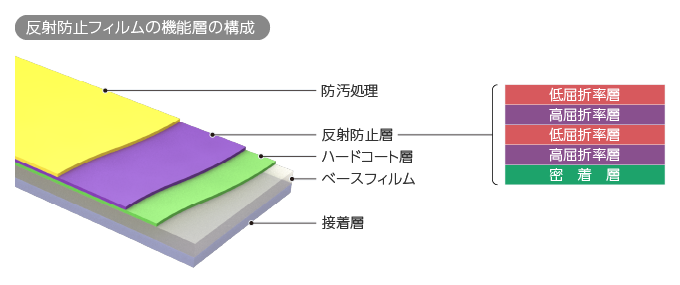

反射防止フィルムとは、ディスプレイなどの光学機器の表面で発生する外光の反射を抑制することで、視認性の低下防止をねらったフィルムです。反射防止を英語で表したAnti-Reflectionの頭文字をとって「ARフィルム」とも呼ばれ、近年では大型テレビやパソコンのモニター、自動車のカーナビゲーションシステムやクラスターパネルなど、さまざまなディスプレイ活用されています。一般的に反射防止フィルムは、ベースとなるフィルムの表面に、反射防止の光学特性を持った薄く透明な膜を積層させた構造をしています。

それでは、反射防止フィルムが光の反射を抑制するしくみを見ていきましょう。例えば水面がきらきら光って見えるのは、空気と水の屈折率の違いから、境界面で光の一部が反射されるためです。ディスプレイの表面も空気と接する面が存在するため、透明なガラスカバーでディスプレイを覆っても必ず光の反射が発生します。反射防止フィルムは、その反射をできるだけ抑えるように設計されています。

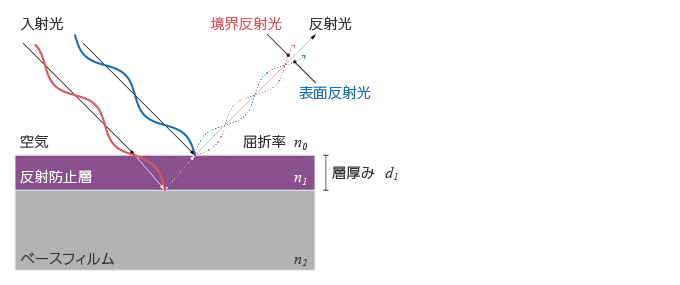

デクセリアルズの反射防止フィルムは上の図のように、接着層、ベースフィルム、ハードコート層、反射防止層からなり、最表面に防汚処理が施されています。さらに反射防止層は、屈折率が異なる複数の膜で構成されています。それぞれの膜の界面で反射した界面反射光と表面で反射した表面反射光の位相をお互いに打ち消し合うように層を構成する材料の屈折率や厚みをコントロールすることで、反射光を低減することができるのです(下図参照)。

反射防止フィルムの製造方法

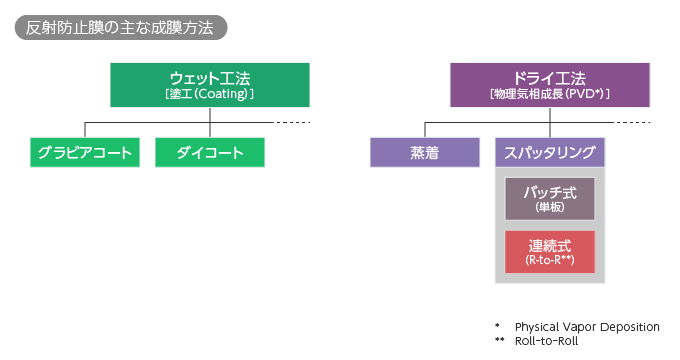

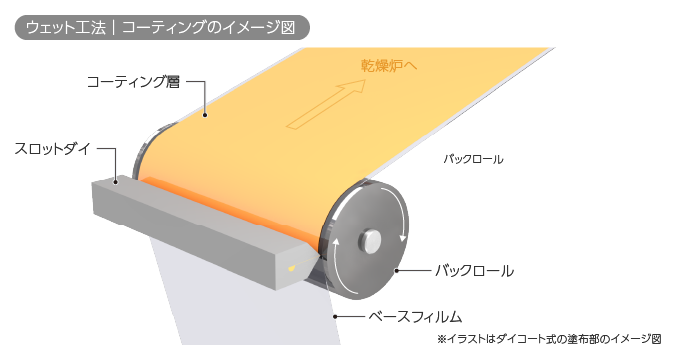

反射防止フィルムに用いられる膜の製造には、大きく分けて「ウェット工法」と「ドライ工法」の2種類の工法があります。ウェット工法はその名のとおり、液体の材料をベースフィルムに塗工し、乾燥させて膜を成形します。

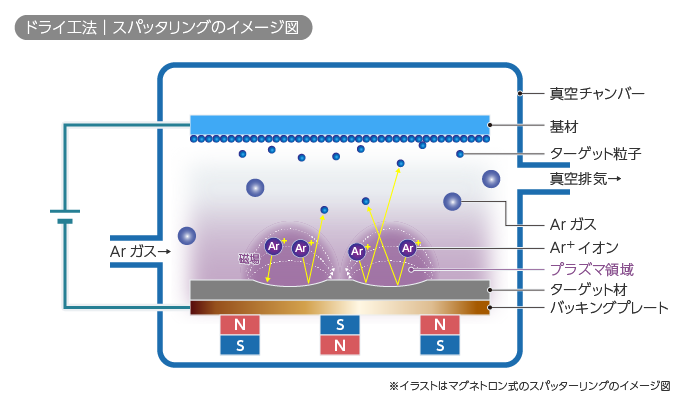

ドライ工法は「蒸着」と「スパッタリング」に分かれ、デクセリアルズではスパッタリングによる製造を行っています。スパッタリングは成膜のための代表的な技術で、真空チャンバー内で膜の材料となるターゲット材に高電圧下でイオン化させたアルゴンイオンを叩きつけ、ターゲット材の原子を弾き飛ばすことで基材の表面に付着・積層させます。スパッタリング工法ではスパッタ装置のチャンバー内に余計なガスがあるとアルゴンイオンがそのガスとぶつかってしまうため、内部を高真空に保つ必要があります。

ロールtoロール方式を採用

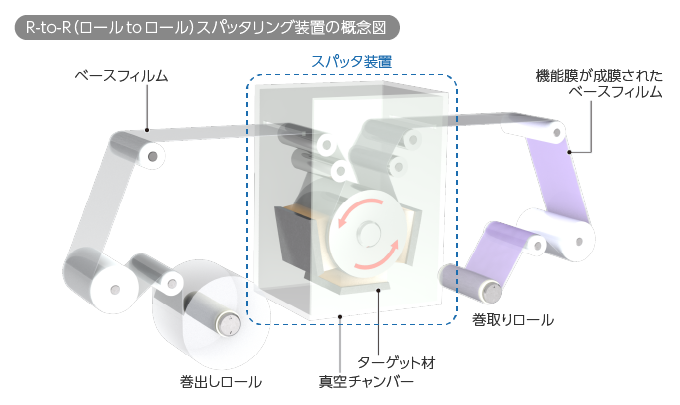

デクセリアルズの反射防止フィルムの特徴は、ロールtoロール方式で生産されていることです。ロールtoロール方式とは、「ロール状に巻かれた材料から生産ラインに連続的に材料を供給・処理をおこない、ロール状に巻き取る手法」を指し、切れ目なく安定した加工ができることから、加工品質と生産効率の高い優れた手法です。

反射防止フィルムの製造では、幅広い波長の光に対応するために、異なる屈折率を持つ光学薄膜を積層する必要があります。そのためデクセリアルズでは、それぞれの膜ごとの金属材(スパッタリングターゲット)をスパッタ装置内に配置し、ロールに巻かれたフィルムを一度通過させるだけで複数の膜を形成できるようにしています。反射防止膜の成膜後のフィルムには防汚処理がなされ、必要に応じて粘着層が形成され、出荷されます。

デクセリアルズの反射防止フィルムの4大特徴

最後にデクセリアルズの反射防止フィルムの4つのメリットをご紹介します。

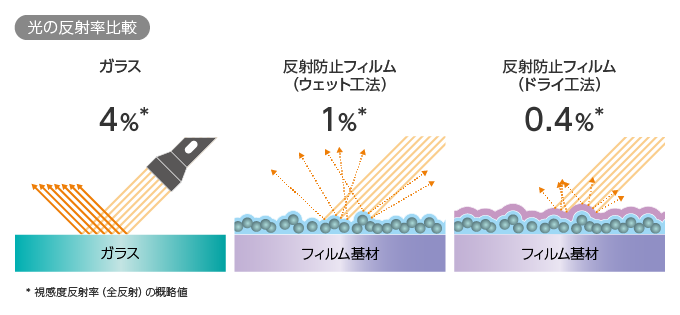

1つ目は、高い反射防止機能を実現できることです。下記の図は、左から「何も処理していないフィルム」「ウェットコートを施したフィルム」「ドライコートを施したフィルム」の、反射率を示しています。前者2つが4%、1%の反射率であるのに対し、デクセリアルズのドライコートの反射防止フィルムはわずか0.4%の光しか反射しません。それにより、ディスプレイなどの高い視認性を実現することができます。

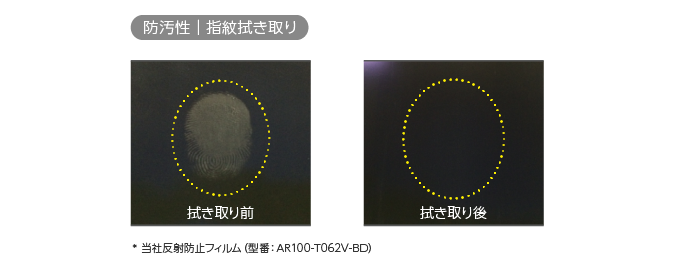

2つ目が「防汚機能に優れていること」です。デクセリアルズの反射防止フィルムの表面は、フライパンなどの汚れ防止に用いられる一般的なフッ素系樹脂よりも撥水性に優れたフッ素系樹脂で防汚膜を形成しています。そのため、実使用時に付着する指紋などの汚れを簡単に拭き取ることができます。下記写真はデクセリアルズの反射防止フィルムにあえて指紋をつけた後(左)、それを拭き取った写真(右)です。きれいに指紋の脂が落ちていることが確認できます。

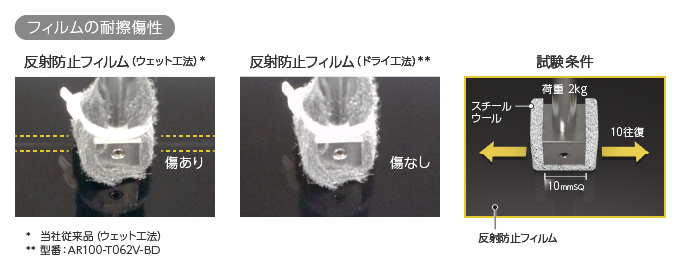

3つ目が、「耐擦傷性に優れていること」です。反射防止フィルムはデバイスの表面に貼られるため払拭などによる外力を直接受ける材料になります。デクセリアルズのドライ工法による反射防止フィルムは、反射防止層が無機膜でできていることから2kgの荷重でスチールウールを押さえつけて擦る試験(10往復)においても傷が付かず、ウェット工法で作られたものに比べて耐擦傷性に優れていることが確認されています。

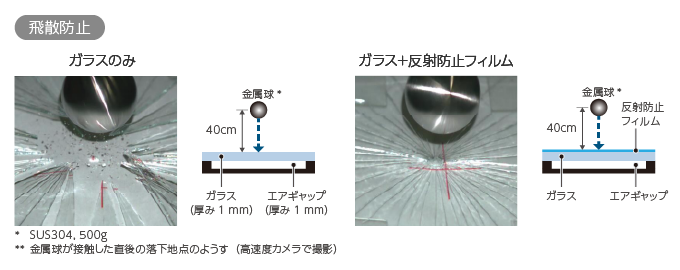

4つ目が「飛散防止機能を付加できること」です。ガラスやプラスチックのカバー表面に反射防止フィルムを貼ることで、衝撃が加わってカバーが割れてしまったとき、破片が飛散することを防ぐことができます。とくに自動車のディスプレイでは、事故時の破片飛散による怪我を予防するため、反射防止フィルムを貼ることが有効な対策となっています。

以上、当社の反射防止フィルムのしくみ、生産方法、メリットについて解説してきました。現在、デクセリアルズが製造販売する反射防止フィルムは、その目的から人の目に見える可視光の反射を低減させる機能を持たせていますが、この技術を応用することで、様々な波長の光(紫外線・赤外線など)に対する制御機能の提供も可能と考えています。今後も新たな可能性の探求を続けてまいります。

関連記事

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら