- 電子部品関連

過充電・過電流から守る。二次保護ヒューズ(SCP)の最新トレンドと技術

目次

高まる二次保護ヒューズ(SCP)の小型化と低抵抗化のニーズ

二次保護ヒューズであるセルフコントロールプロテクター(SCP)。リチウムイオンバッテリーに過充電や過電流が起きた際、確実に回路を遮断してバッテリーが危険な状態になることを防ぐための表面実装タイプのヒューズ素子です。1994年にソニーケミカル(当時)が生産を開始して以来、リチウムイオンバッテリーの普及にともなってさまざまなエレクトロニクスデバイスに搭載されてきました。

近年は、急速充電ができるスマートフォンの需要が高まったことにより、SCPも急速充電に対応する製品が求められるようになっています。

急速充電において一番の問題となるのは、従来品よりも短時間に多くの電流を流すことにより、内部の回路が発熱しやすくなることです。そのため急速充電対応のスマホでは、バッテリーの保護素子ヒューズも発熱しにくい低抵抗の製品であることが求められます。また同時に狭いスマートフォン内部の空間でヒューズがスペースをとらないよう、さらなる小型化のニーズも高まっています。

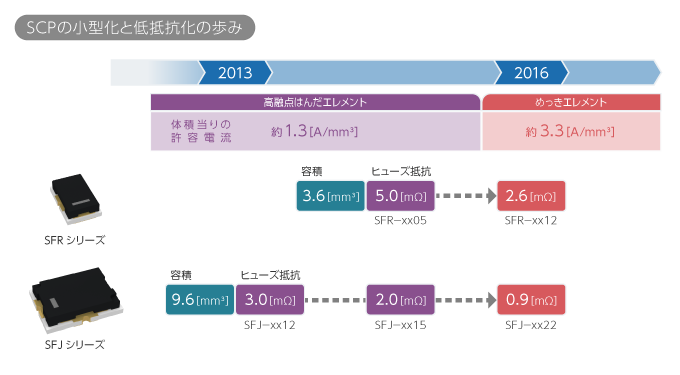

新開発のヒューズエレメントで驚異的な低抵抗化を実現

デクセリアルズは常に時代の要望に応じた製品をいち早く製品化してきました。中でも2016年に開発した22A(小型)SFJシリーズ(型番:SFJ-xx22)、12A(小型・薄型) SFRシリーズ(型番:SFR-xx12)は、体積あたりに流せる電流が従来製品の約1.3A/mm3から22A(小型)SFJシリーズで2.3A/mm3、12A(小型・薄型) SFRシリーズで3.3A/mm3と大幅に増加。同じ製品サイズの12A(小型) SFJシリーズ(2013年)と22A(小型) SFJシリーズ(2016年)で比べると、3.0mΩから0.9mΩへと約3分の1の低抵抗化を実現しました。

新たな二次保護ヒューズ(SCP)シリーズの誕生

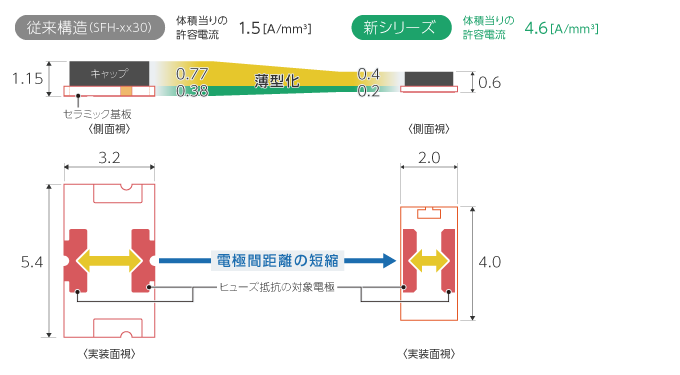

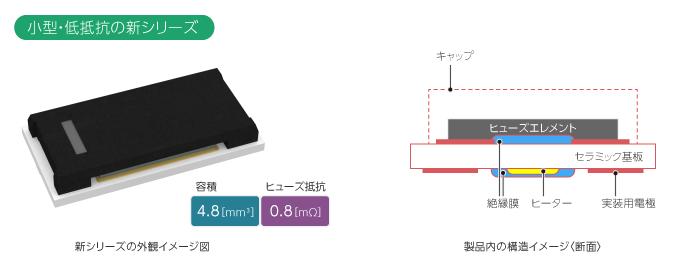

そして2021年、さらなる「小型低抵抗化ヒューズ」として新たなシリーズが登場する予定です。ここからは、新シリーズの特長と技術について解説します。

上記の図のとおり、新シリーズは、従来品のSFHシリーズに比べて、黒いキャップ部分、その下の白いセラミック基板部分が、ともに約50%ずつ薄くなっています。セラミック基板の厚み0.2mmは現時点で当社の表面実装型ヒューズの中で最も薄く、これによりヒューズエレメント部分とセラミック基板の裏面(エレメント搭載面の反対面)にある実装用電極間の距離を短くすることに成功しました。これらの改善によって体積あたり4.6A/mm3の電流を流すことが可能となりました。

ヒーターの位置を製品内部から基板実装面に

さらに工夫をしたのが、ヒューズエレメントを溶断するヒーターの位置です。従来品ではヒューズエレメントに効率よく熱を伝えるためにキャップ内に収めていたヒーターですが、薄型を追求するため基板を従来の2分の1の薄さにしたことで基板の実装面に移動させても十分に熱が伝わり、エレメントを溶断できるようになりました。同時にヒーターを基板の実装面に移したことで、キャップも約半分の高さにできたことから、更なる薄型化が可能になりました。こうしたさまざまな工夫によって、新シリーズは圧倒的な小型化と低抵抗化を同時に実現しました。

急速充電はさらに進化。小型化と低抵抗化で広がる新デバイスの可能性

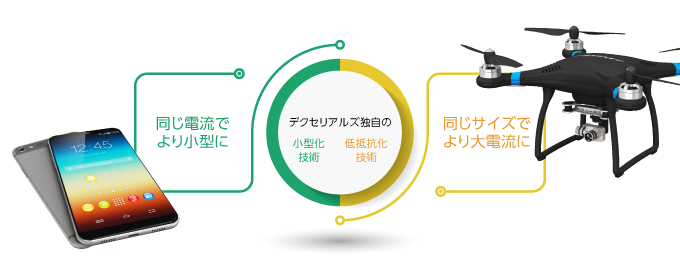

デクセリアルズが持つSCPの小型化・低抵抗化技術は、「同じ電流であればより製品を小型化すること」と「同じサイズの製品であればより大きな電流を流せること」を可能にします。また、デバイスの発熱を抑えることにより、急速充電をはじめとする新たな機能実現を陰で支えています。当社ではスマホやタブレットのような電子機器はもちろん、ドローン、電動工具などのリチウムイオンバッテリーを使って動くさまざまな機器に対応する各種の製品を取り揃え、お客さまのニーズにお応えしています。

関連記事

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら