- 電子部品関連

LFP電池とセル保護のこれから: 電動バイク、ESSへの広がりを見据えた技術の可能性

目次

テクノロジーが変える、私たちの日常

スマートフォン、電動バイク(以下、E-bike)、太陽光発電システム。これらの技術革新を支えるのは「バッテリー」です。中でも、LFP電池(リン酸鉄リチウムイオン電池)は、安全性、長寿命、低コストで注目を集めています。従来のリチウムイオン電池(LIB)の課題を克服し、持続可能なエネルギー社会の実現に貢献するLFP電池は、電動バイクから再生可能エネルギー貯蔵システム(ESS)、さらには民生機器まで幅広い分野で活用が広がっています。

本記事では、LFP電池の基礎知識、市場での成長性、アプリケーション、そしてデクセリアルズの二次保護ソリューション「セルフコントロールプロテクター(SCP)」について詳しく解説します。

LFP電池とは

LFP電池(Lithium iron phosphate battery)は、正極材料にリン酸鉄リチウム(LiFePO4)を使用するLIBの一種で、高い安全性と長寿命が特徴です。EVやE-bikeなどのモビリティ用途をはじめ、再生可能エネルギー貯蔵システム(ESS)などで採用が進み始めており、持続可能なエネルギー社会への貢献が期待されています。

LFP電池は1997年にアメリカのテキサス大学で初めて論文として報告されました。熱安定性が高く、発火リスクが低いことが評価されましたが、正極にニッケル、マンガン、コバルトまたはアルミニウムを用いるLIBの「NMC/NMA電池」に比べてエネルギー密度が低かったため、商業化が進みませんでした。2000年代初頭には、カナダの企業がナノテクノロジーやカーボンコーティング技術を駆使して性能を向上させましたが、生産コストや特許ライセンスの制約により、量産は限定的でした。

そんな状況を一変させて、2010年代以降にLFP電池の量産を主導するようになった国が、中国です。中国のバッテリーメーカーはカナダの企業から特許ライセンスを取得すると、豊富な原材料と政府の電動モビリティ産業支援策を背景に、低コストでの大規模生産を実現。レアメタルのコバルトやニッケルを使用しないLFP電池は、中国の低価格帯EV市場に適しており、コスト競争力とスケールメリットで世界市場を席巻しました。一方で欧米では依然としてエネルギー密度の高い電池が主流だったため、LFP電池の採用は限られていました。

しかし2022年にLFP電池の主要特許の特許権が消滅したことで、欧米のメーカーも急速にLFP電池に関心を向けるようになりました。コバルトやニッケルの供給リスク、脱中国依存の動き、電動モビリティ分野での採用拡大が後押しし、欧米企業もLFP電池の国内生産を模索中です。

なぜLFP電池が選ばれるのか? 次世代バッテリーの挑戦

LIBの限界を乗り越える新たな選択肢としてLFP電池が注目される理由は、LIBの電池技術が抱える3つの重大な課題を、革新的なアプローチで解決できるからです。

より高い安全性を実現

LIBは、可燃性の有機溶媒を電解液に使用するため、火災のリスクを孕んでいます。それに対してLFP電池は、正極の材料のリン酸鉄リチウムの化学構造が安定しているため熱安定性が高く、過熱や衝撃による発火・爆発リスクが低いという特長があります。LIBを搭載したEVやエネルギー貯蔵システム(ESS)での火災事故が世界で散発し、安全性が重視されるようになった結果、熱暴走リスクが低く、大規模な電池システムに適しているLFP電池が選ばれるようになっています。

エネルギー密度が向上

電池の重量あたりの電気容量(重量エネルギー密度)は、電動バイクの航続距離やESSのエネルギー効率に直結します。そのためエネルギー密度を高めることが、次世代電池の最大の課題となっています。当初、LIBに比べて低エネルギー密度だったLFP電池は、技術革新によって安全性を犠牲にすることなく、エネルギー密度の向上を続けています。

レアメタルに依存せず環境負荷が低い

ニッケルやコバルトなどの産出国が限定されるレアメタルに依存せずに、LFP電池は製造が可能です。その結果、政情や資源規制など、生産国特有のリスクを回避しつつ、レアメタル採掘がもたらす環境負荷を減らし、よりサステナブルな電池技術を実現できます。また充放電のサイクル寿命が倍以上あることから、バッテリーの廃棄・リサイクルにともなって発生するコストも低減できます。

以下はLFP電池と、LIB(ニッケルマンガンコバルト電池、ニッケルマンガンアルミニウム電池)との比較表です。

| 比較項目 | LFP電池 | NCM/NCA電池 |

|---|---|---|

| 正極材料 | リン酸鉄リチウム | ニッケル、コバルト、マンガン/アルミニウム |

| エネルギー密度 | 90〜160 Wh/kg | 150〜220 Wh/kg |

| 安全性 | 比較的高い | 比較的低い |

| サイクル寿命 | 2,500サイクル以上 | 1,000〜2,000サイクル |

| コスト | 低価格 | 比較的高価 |

| 温度耐性 | 優れている | 制限あり |

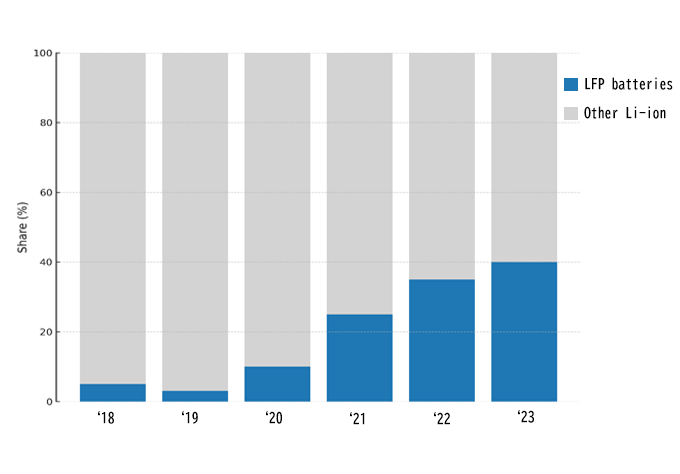

LFP電池市場の成長性

グローバル市場の予測では、LFP電池市場は2030年までに年平均成長率(CAGR)で約20%の拡大が見込まれています。(出典:世界のEV市場の動向を変えるLFPバッテリー |EVブースター)特に再生可能エネルギーの貯蔵やスマートグリッド、モビリティ分野での需要拡大が市場成長を支えています。

LFP電池は従来の電池技術と比較して、希少金属の使用を控えるために製造コストが低くなり、とくにNMC電池よりも安く製造することが可能です。そのため市場での価格は従来のLIBよりも3割ほど安くなると言われています。中国政府は過去に同国内でエネルギー貯蔵システムの導入支援策を進めており、その結果、国内市場でのLFP電池の普及が加速しました。これが国際市場への展開につながっています。

また北米のモビリティ分野の主要メーカーをはじめとする世界的な企業がLFP電池の採用を本格化しており、今後電池材料の供給不足や、LFP電池のさらなる技術的成熟により、安全性、コスト効率、持続可能性の観点から、LFP電池の市場拡大はさらに続くと見られています。

LFP電池の主なアプリケーション

2025年現在、LFP電池の主なアプリケーションとして以下の用途が挙げられます。

電動バイク(E-bike)

中国、欧米を中心に普及を続ける電動バイクでも、新車の開発にLFP電池の採用が進んでいます。とくに東南アジアの都市部の高温環境や、衝撃が多い使用条件下でも、熱暴走リスクが低いという安全性が高く評価されています。また、日常的な充放電サイクルに強いLFP電池は、バッテリー交換頻度を減らすことができるため、長期的なコスト削減にもつながっています。

従来の鉛蓄電池などと比較して大幅な軽量化が可能なことも大きな利点です。これにより電動バイクのトータルの走行距離や取り回しが向上し、ユーザーの満足度の向上につながっています。LFP電池はさまざまな気象条件下でも安定した性能を発揮するため、通勤や個人の移動手段としても、また配達などの業務用途においても高い信頼性が評価され、企業の採用も進んでいます。こうした利点から特に都市部の移動手段として、LFP電池を搭載した電動バイクの需要は今後さらに拡大すると予測されています。

再生可能エネルギー貯蔵システム(ESS)

太陽光発電や風力発電などの再生可能エネルギーシステムにおいて、LFP電池は安定した電力貯蔵を実現することができます。過酷な環境条件下でも安定した性能を発揮し、メンテナンス負荷が低いことがメリットです。

調査会社Fastmarketsによると、ESS(エネルギー貯蔵システム)市場全体の需要は、2022年の66GWhから2023年には140GWhに倍増し、2033年には約840GWhに達すると予測されています。そのうちおよそ87%をLFP電池が占めると見込まれており、今後の再生可能エネルギー用途における中核技術としての位置づけが期待されています。

参考記事:Growing LFP adoption drives need for more transparency across chemistry’s supply chain – Fastmarkets

バックアップ電源システム(UPS)

病院、データセンター、通信施設などの重要インフラにおいて、LFP電池は信頼性の高いバックアップ電源として採用が進んでいます。交換頻度、メンテナンス頻度が少なくて済むことから、長期的なコスト低減を実現できます。

海洋・船舶用機器

プレジャーボートやヨットの電装品、トローリングモーター、魚群探知機、GPS、ソナーなどの航行支援機器、さらに自動気象ブイや海洋観測センサーなど、海洋環境で使用される機器の電源にLFP電池の採用が進んでいます。振動や、衝撃といった厳しい条件下でも安定した性能を発揮し、LIB(NMC系)に比べて発火リスクが低く、安全性と信頼性の高い電源としての役割を果たしています。

ノートPC・家庭用電動工具

とくに最近の注目すべきトピックは、大手PCメーカーが次世代ノートパソコンでのLFP電池採用を進めていることです。採用の理由は、安全性と長寿命という特性がモバイルデバイス市場でも評価され始めたことです。今後、電動工具、家庭用電子機器など他の小型エレクトロデバイスにおいても、LFP電池は安全性と環境負荷・コストの低さから採用が拡大することが予想されています。従来のLIBと比較して、発火リスクの低減と長いバッテリー寿命が、モバイルデバイスのユーザーにとって大きなメリットとなっています。

LFPの二次保護ソリューションとしての二次保護素子

従来製品に比べて熱的安定性が高く、安全性の高い電池として評価されています。

しかし、過充電状態が長く続くと電池温度が上がり続け、ついには安定領域を超えて熱暴走が誘発され、最悪の場合は発火につながることが研究で報告されています。こうした万が一の事態に備え、適切な二次保護が重要となります。

デクセリアルズの表面実装型ヒューズ「セルフコントロールプロテクター(SCP)」は、LIBで過充電や過放電が起こった際に、物理的にヒューズが熱によって溶断されることで回路を遮断します。すでにノートパソコンをはじめとするモバイル機器で採用されております。とくに新製品のSFJ-1022(3セル LFP対応品)は、LFP電池の電圧範囲をカバーするために新たに回路を設計しており、拡大が続くLFP電池の二次保護ソリューションとしても最適です。

22A(小型) SFJシリーズ セルフコントロールプロテクター(SCP)

ESSをはじめとする大容量システムや、E-bikeなどさまざまな用途への導入が進んでおり、今後はさらなる展開も視野に入れています。

デクセリアルズは今後もLFP電池の安全設計に対応する製品を展開し、その安全な活用を支えることで、より豊かで安全な社会を支えていきます。

関連記事

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら