- 接合関連

製品へのダメージを防ぎ、部品実装にも耐える「工業用保護テープ」

製造技術を担当しているエンジニアの皆さま、電子回路基板の組立や各種部品の製造工程で、こんな悩みはありませんか?

- 製造過程で異物が製品に付着し、不良になってしまう

- リフロー工程で保護テープが変形し、保護ができなくなる

- 保護テープを剥がした際に糊残りが発生し、糊を取り除く作業が面倒

- 複雑な形に対応した保護テープがほしい

電子回路基板や各種部品を製造する工程では、製造過程で異物が付着したり混入することで、不具合が生じるケースがあります。例えば、リフロー工程で雰囲気中の埃やごみ、はんだやフラックスなどの飛沫が部品や基板に付着したり、基板などに穴を開ける際に切削屑が付着したり、洗浄水が残留することがあります。このほか、輸送中にも梱包材や緩衝材の屑などのダストが付着・混入する場合があります。

こうしたさまざまな異物から対象物を保護するために使われているのが、デクセリアルズの「工業用保護テープ GPF8100」です。

なかでも粘着剤に耐熱性を付与した当社の「工業用保護テープGPF8100」は、電子部品を基板に搭載する「リフロー工程」などの高温工程でも変形せず、剥がした際に粘着剤が製品に残らないように設計された片面テープです。貼るだけで効率よく、確実に製品を保護できることから、さまざまな電子基板の製造に活用されています。

本記事では、製造工程における切実な悩みを解決する、当社の工業用保護テープの特長についてご紹介します。

目次

「工業用保護テープGPF8100」が活躍する製造現場での使用例

「工業用保護テープ GPF8100」は、電子デバイスや精密機械の製造現場での使用を想定した製品です。保護テープを必要な箇所に貼ることで、輸送中の埃や段ボール屑、リフロー工程で発生するはんだ屑やフラックス、塵、掘削工程の切削屑などから、重要な部品を確実に保護します。

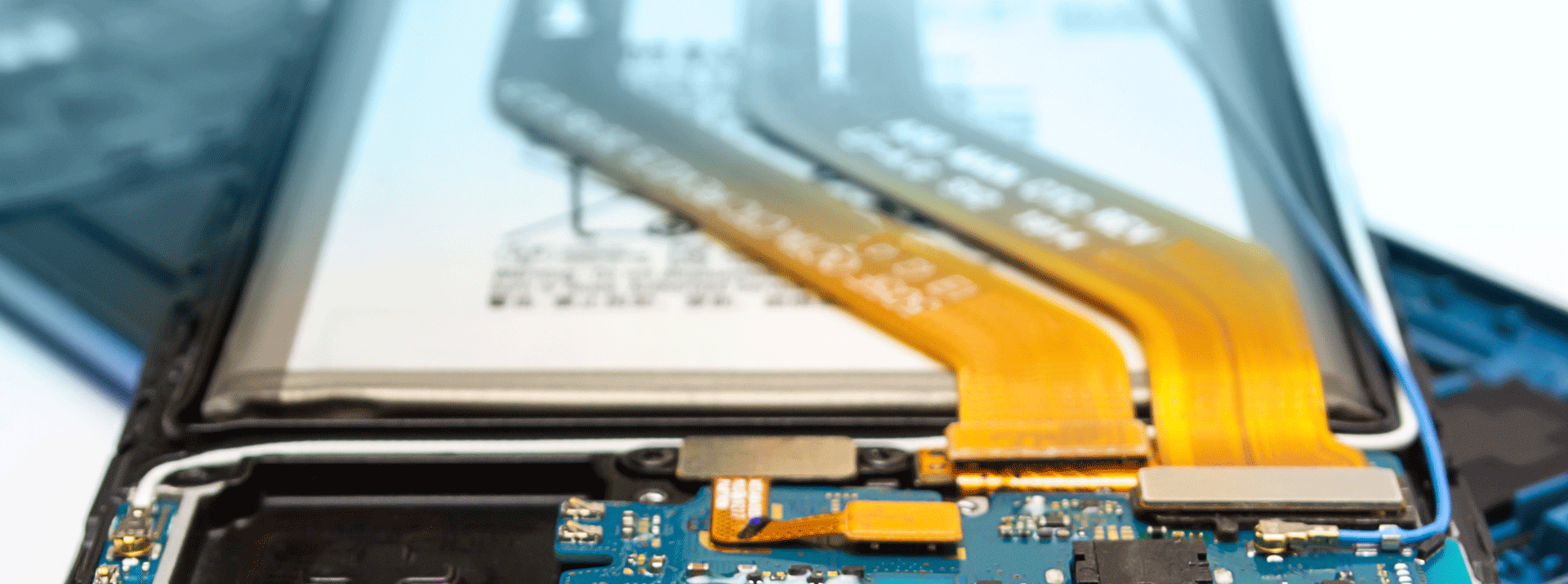

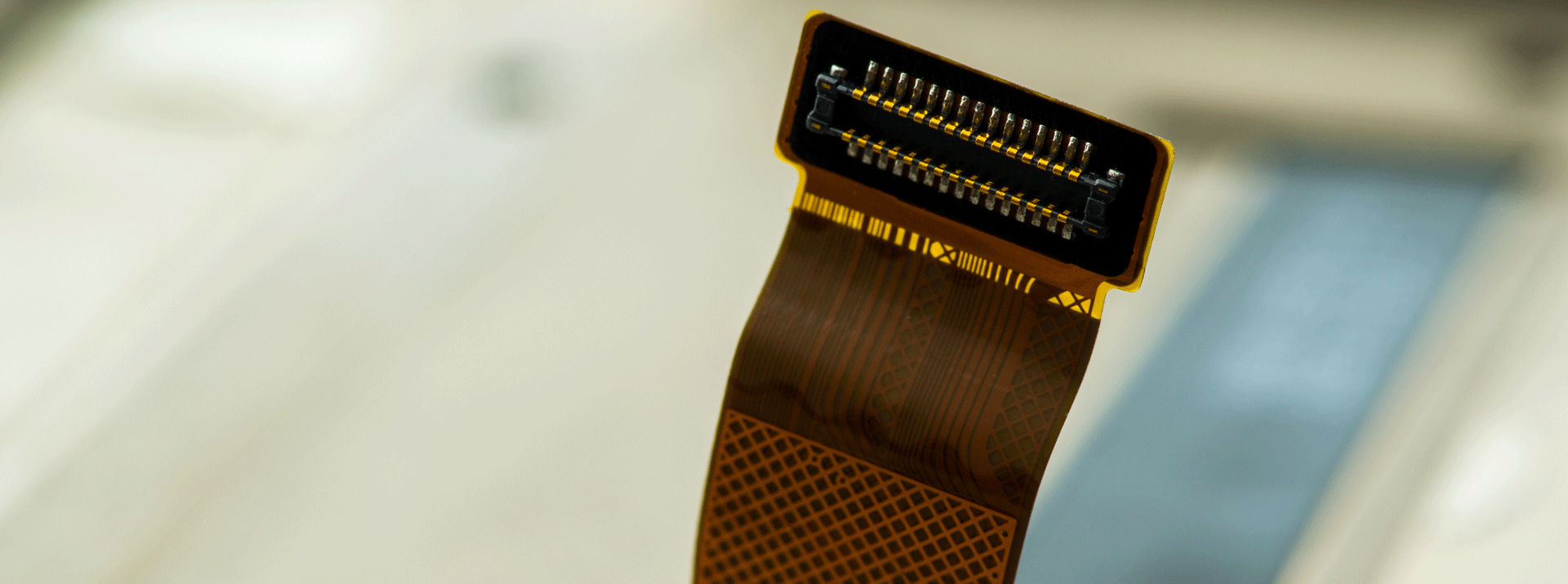

電子回路基板、例えばPCB(プリント基板)の端子部分に保護テープを貼ることで、リフロー工程での端子表面の汚染を防ぐことが可能です。また、切削加工を必要とするレンズなどの部品では、加工しない部分の表面保護としても活用でき、加工中に発生する異物による製品汚染を効果的に防止します。

確実な製品保護と使いやすさの両立を実現

高温工程にも対応

一般的なテープは、リフロー工程の高温にさらされると、テープが変形したり、粘着剤が溶けたりするおそれがあります。しかし、当社の工業用保護テープは、リフロー工程などの高温工程後も安定して保護性能を維持します。

剥がしても糊残りなし

せっかく保護テープを使用しても、剥離時に粘着剤が残ってしまうと、糊の除去のために追加の洗浄工程が必要になる場合があります。当社の工業用保護テープは、粘着剤の残留がなく、洗浄工程を省略できるため、作業効率が大幅に向上します。

柔軟な形状加工に対応

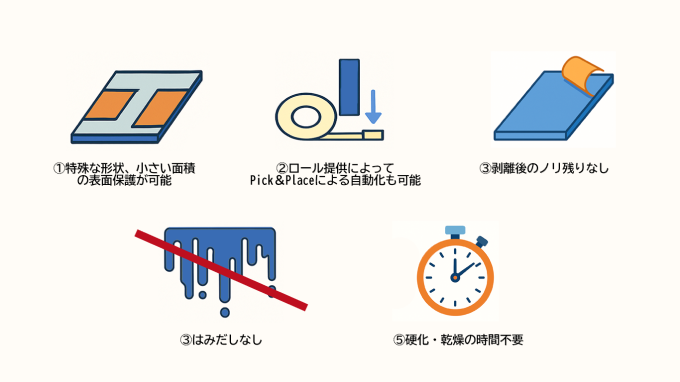

当社の工業用保護テープは保護対象の形状に適合する形状に外形加工を行いシートに配置した状態で提供することが可能です。さらに、あらかじめ形状加工されたテープを長尺のロール状フィルムに配置したロール状製品として提供することもでき、製造工程の自動化にも対応可能です。

熱処理後でも糊残り無く、剥離可能な耐熱性粘着剤を使用

前述のように高温での処理を伴う製造工程で使われる保護テープは、工程を通過したあとでも糊の残りが無く、きれいに剥離できる必要があります。一般的な保護テープの場合、使われている粘着剤の耐熱性が低い場合があり、下記の写真のように糊残りが発生するケースがあります。

製造工程で使用する保護テープを検討する場合には、こうした問題が起こらないように目的に合ったテープを選択することが大変重要です。デクセリアルズでは長年に渡り粘着テープの開発・製造を手掛けてきており、熱処理を行った後でも糊残りがない粘着剤を開発、「工業用保護テープGPF8100」として商品化しました。

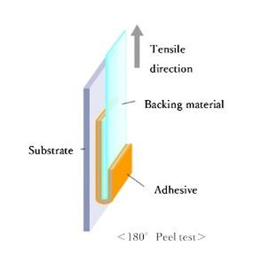

180°ピール試験による接着強度の比較データ(熱処理前後)

Adhesion strength 180°

| 基板 | 初期 | 熱処理後 |

|---|---|---|

| ガラス | 0.1 N/20mm | 0.4 N/20mm |

・熱処理条件:260℃/5分保管

液状タイプより優れるシートタイプ保護剤のメリット

製造工程における製品の保護を目的とする商品としては、液状の保護剤も市場には存在しています。それらの製品は、保護したい箇所に水溶性の保護剤をディスペンサーなどの塗布機を使って塗布し、硬化させることで任意の形状の製品保護を実現します。

液状の保護剤は、立体的な形状の製品を保護するといった面では優れていますが、塗布時にはみ出しが発生するなど塗布形状が安定しない場合があったり、硬化・乾燥に時間を要します。加えて、保護の必要がなくなった段階で保護剤を取り除くための洗浄が不可欠となります。一度の洗浄では保護剤がすべて取り除けない場合には複数回の洗浄が必要となるなど、さらなる手間が生じることもあります。

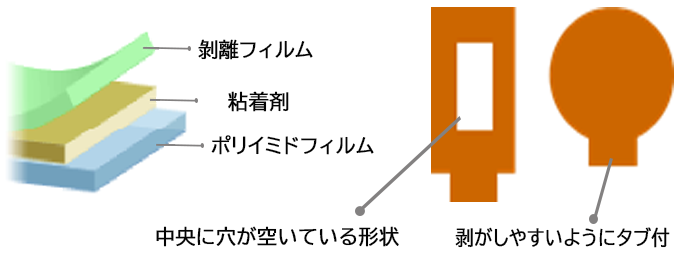

固形化した液状保護剤も物理的に取り外せないわけではありませんが、テープのように容易に取り外すための“タブ”(つまみ)をつけられないため、どうしても取り除きに手間と時間がかかります。そのため、使い勝手の点ではテープ状の保護製品が優れていると考えています。

ニーズに合わせて自在にシート形状を加工

さまざまな形・大きさの製品を保護するためには、保護シートも多種多様な形にカスタマイズする必要があります。デクセリアルズでは自社の強みである形状加工技術を用いて、以下のような複雑な形状でも自在に保護シートをカスタマイズすることが可能です。

さらに保護シートをロール化することで、製造工程の自動化にも対応可能です。対応可能なロール幅は最大480mmですが、それ以上のサイズがご入用の場合も、まずは当社までお問い合わせください。

対応可能な形状例と、シートタイプ保護剤の特徴を示したイメージ図が以下です。

複数社が分担する製造プロセスで部品を一気通貫で保護

当社の工業用保護テープは、液状保護剤のようにディスペンサーの調整などの手間が無く、貼るだけで保護を実現します。さらに糊残りなく剥がすことができるため、洗浄工程の必要もなく、シンプルな製造工程を実現させることが可能です。

リフロー工程など高温環境下での製品保護にお悩みの製造技術者の皆さまにとって、「貼って・剥がすだけ」で済む当社の「工業用保護テープ GPF8100」は、製造工程の簡素化と品質維持に貢献する選択肢です。

電子部品の製造では、サプライチェーンの川上から川下で、数社が生産プロセスを分けて担当するケースがよくあります。例えば、A社が部品を製造、B社がリフロー工程で部品を基板に実装、C社がそれらを組み立てて商品化を行うといった場合に、GPF8100は「A社で保護テープ貼り付け(保護開始)」「B社でのリフロー工程での異物付着・汚染防止(保護機能発揮)」「C社での組み立て完了後、保護テープ剥離(保護終了)」を実現することができ、サプライチェーンの中で横断的に大切な部品を守ります。

本製品にご関心をお持ちの方は、ぜひ下記リンクより製品詳細をご確認ください。技術資料のご提供やサンプルのご依頼も承っております。

関連記事

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら