- 接合関連

普及が進む「生体認証機能付クレジットカード」に欠かせない技術へ——異方性導電膜のメリット

目次

市場拡大が続くデクセリアルズのICカード向け異方性導電膜(ACF)

私たちデクセリアルズは、ディスプレイなどの電子機器の回路を接続・接着する素材として、異方性導電膜(ACF)を世界で初めて開発し、長年にわたって販売してきました。近年は、クレジットカードなどのICカードの回路接続に特化したACFを開発し、世界各国で使用される接触/非接触ICカードへの採用が進んでいます。

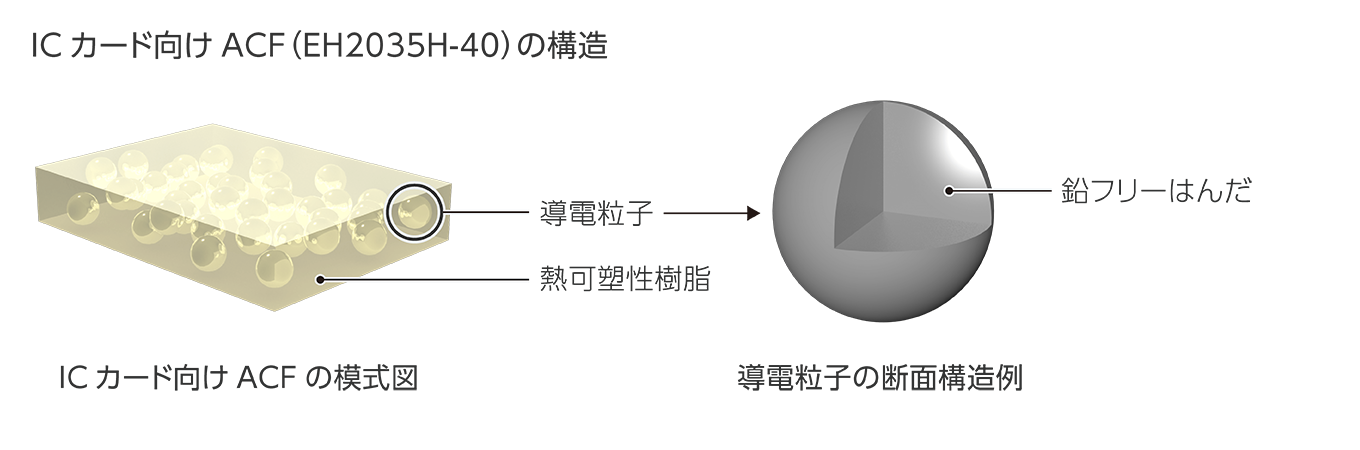

そして2021年、新たにICカード接続用に開発したのが、「鉛フリーはんだ粒子」を用いたACF「EH2035H-40」です。この新しいICカード向けACFは、これから世界中で急速に普及することが確実視される「生体認証機能付クレジットカード(生体認証カード)」に搭載される「指紋認証センサー」の接続・接着用として採用されることを想定して開発されました。指紋認証カードはすでに欧米の主要な銀行、金融機関が旧来の接触/非接触ICカードに代わって採用することを表明しており、爆発的に市場が拡大すると予測されています。

なぜ生体認証カードの接続には異方性導電膜(ACF)が最適なのか

各店舗で使用している従来の決裁端末に「ピッ」とかざすだけで決済が可能な非接触ICカードは、決済のスピードが非常に早く、簡便なことからまたたく間に普及しました。しかし、カードを取得した本人以外の人物が不正利用する危険があるため、国ごとに決済金額の上限が決められています(日本の場合は1万円までがスタンダード)。

それに対して、生体認証カードは、ユーザーの指紋をはじめとする「その人にしかない生体情報」をカードが読み取り、認証をとれた場合のみ決済が許可されます。セキュリティが大幅に向上することから、従来の非接触ICカードと比較して決済金額の上限を引き上げることができ、ユーザーはより多くの機会でカード決裁が可能となります。従来の接触ICカードで高額決済する際に必要だった、店頭の端末にPINコードを入力するといった手間もいらず、ユーザーの利便性は大幅に向上します。

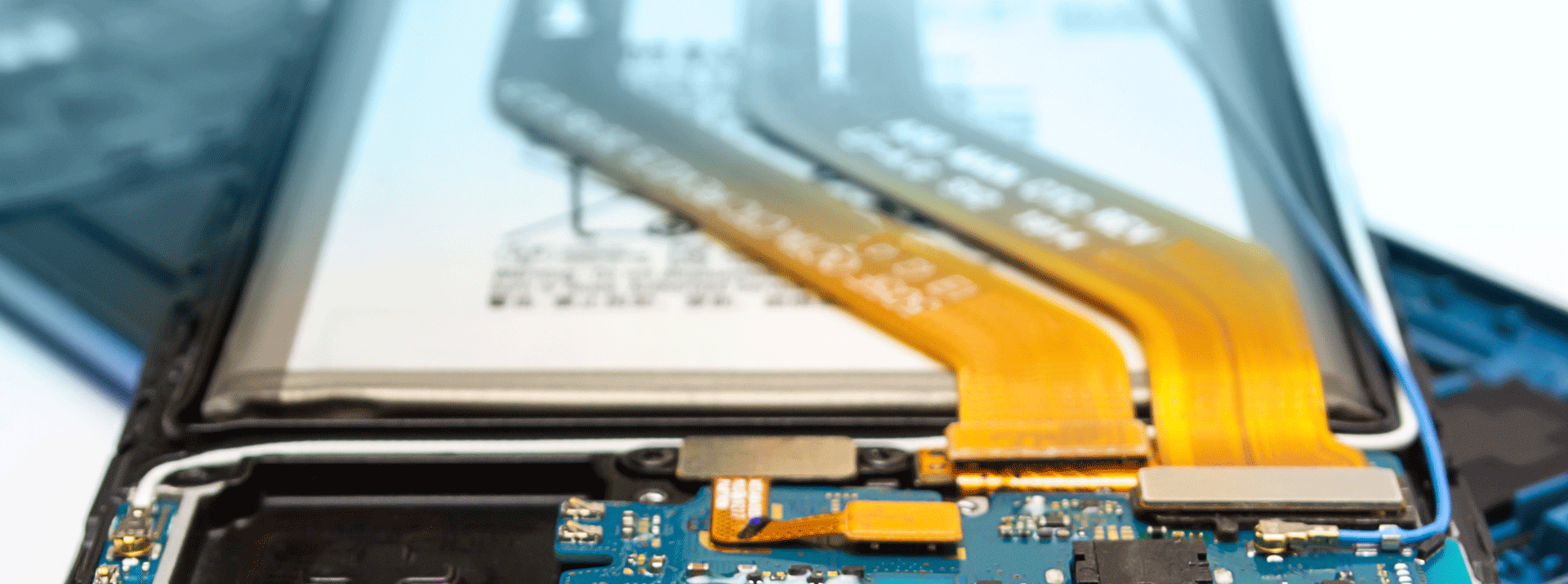

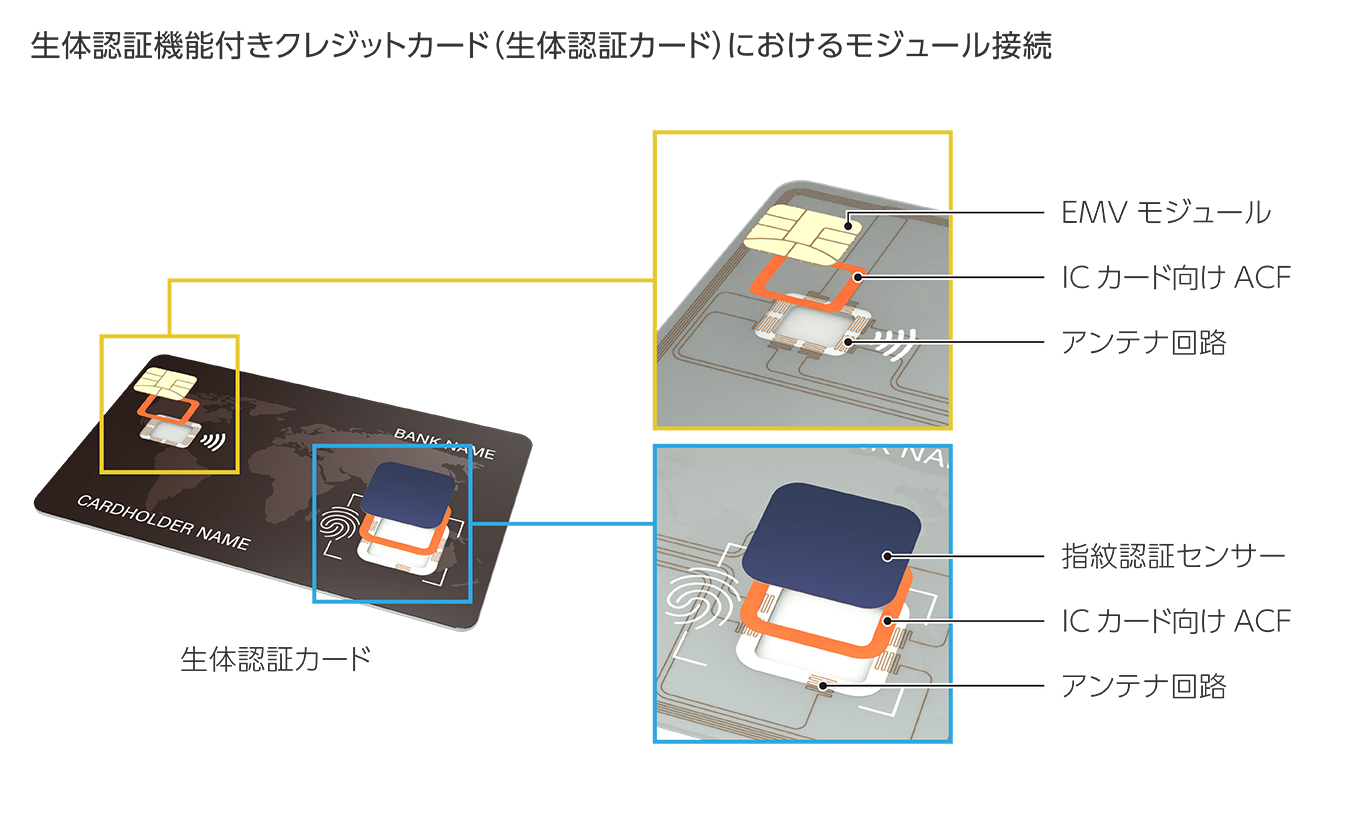

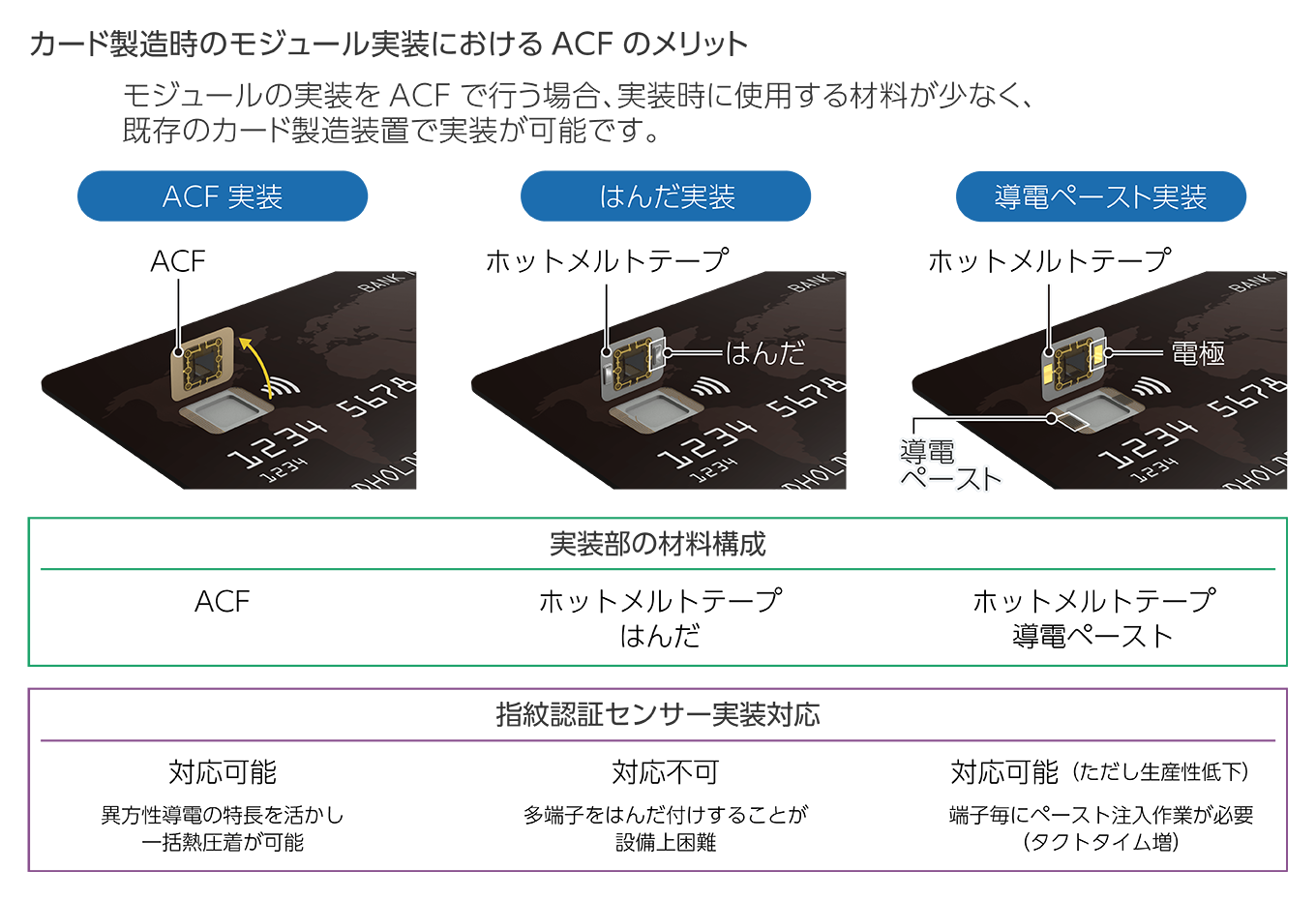

一方で現在、世界中のICカードメーカーの間で課題となっているのが、生体認証カードに搭載される「指紋認証センサー」の実装です。従来の非接触ICカードに搭載されるICモジュールには、電力を供給するための端子と、カードリーダーとデータをやり取りするための端子の2つしかなく、カードに張り巡らされた銅線のアンテナ回路への接続も単純でした。そのため、ほとんどのICカードは、はんだ付けか、はんだ粉末をフラックスに添加した「はんだペースト」によって回路を接続し、チップ自体はホットメルト(熱可塑型接着)テープでカード本体に接着・固定してきました。

しかし、生体認証カードの場合は、EMV モジュール(ICチップ)や指紋認証センサーへとつながる端子の数が4~8個に増加します。そのため、はんだ付けでは設備上の制約から接続することが難しく、また、はんだペーストでは端子の数が増えた分、タクトタイム(1枚の生産にかかる時間)が伸び、生産性が大きく落ちることが予想されます。はんだ付け、はんだペーストともに、接続とは別にホットメルトテープでの固定にも時間が必要となり、これもタクトタイムの増加の要因となります。

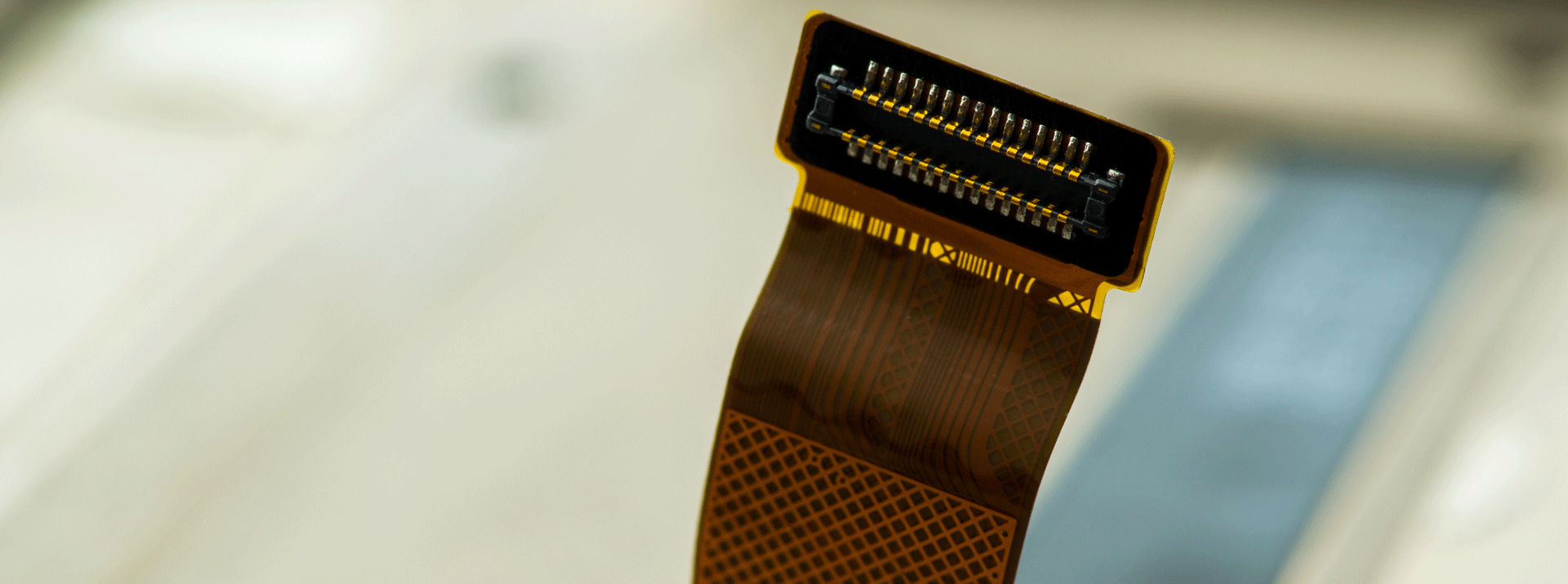

それに対してデクセリアルズのACFは、あらかじめ必要な形状に切り抜いたフィルム状の材料を端子に熱圧着するだけで、「複数回路への接続」と「モジュール(あるいはセンサー)の固定」を同時にかつ確実に実現します。端子の数が8つ以上に増えても問題なく接続と一括貼り付けができ、また固定にホットメルトテープのような別の材料も必要ありません。さらに、カードメーカーであればどの会社でも保有しているチップ接続用の設備で導入することができます。

独自技術として「はんだ粒子」を異方性導電膜(ACF)に採用

また、デクセリアルズのICカード向けACFの優れた点は、2020年に開発した新製品以降、回路接続に「はんだ粒子」を用いていることです。はんだは熱をかけると金属同士が溶けて融合することにより、強固な回路接続を実現します。そのため、指紋認証センサーを搭載したICカードでも、長期にわたっての良好な導通を維持します。

関連記事

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- SHARE

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら

当社の製品や製造技術に関する資料をご用意しています。

無料でお気軽にダウンロードいただけます。

お役立ち資料のダウンロードはこちら