- Elemental Technologies

The Possibilities of New Technology in Cameras and Automotive Applications: Substrate-Free Transfer Type Moth-Eye Structures

Contents

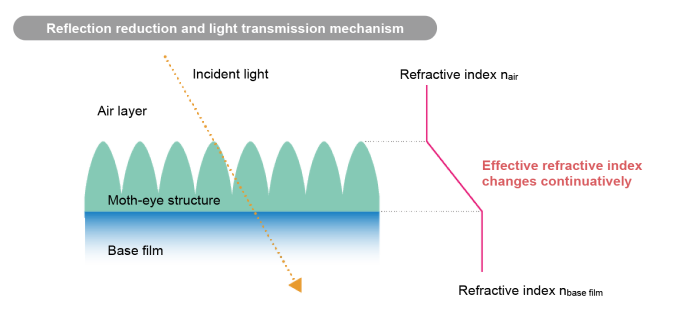

New technology to transfer moth-eye structures with adhesives

The anti-reflection film moth-eye type developed, manufactured, and sold by Dexerials uses a microstructure based on the surface of an eye of a moth, a nocturnal insect, applied to a film substrate. As a result, the product can reduce light reflection at an extremely high level compared to conventional anti-reflection films. By applying this moth-eye structure film on the front and adhesive on the back to a glass or plastic plate, it can reduce light reflection from the surface and improve light transmission. This technology has found applications in diverse areas, including the use in surface protection plates for displays, effectively preventing light reflection.

Dexerials is actively exploring broader applications of moth-eye structures. We are developing a technology that leverages adhesives to transfer these structures to any location, eliminating the need for a substrate as a supporting base.

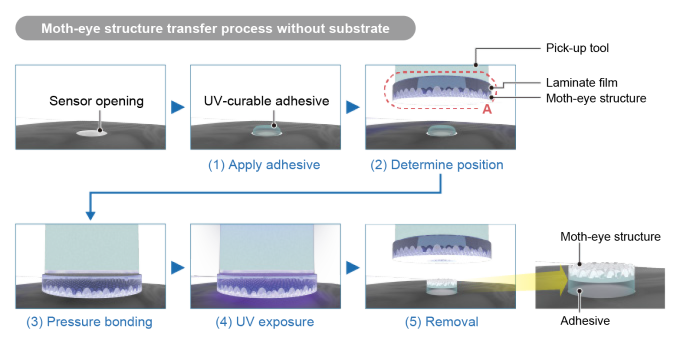

A conceptual diagram for this technology is shown below. In substrate-free microstructure transfer, UV-curable adhesive is first applied to an adherend such as a glass or plastic plate. Next, film with a moth-eye structure laminated onto it (marked “A” in the diagram below) is pressed into the adhesive with the structure side down and exposed to UV light to cure the adhesive. Upon removal of the laminate film, the moth-eye structure in the applied adhesive is retained, enabling it to be transferred to the adherend akin to a sticker. By choosing an adhesive that is compatible with the adherend, we can transfer moth-eye structures onto a wide range of materials.

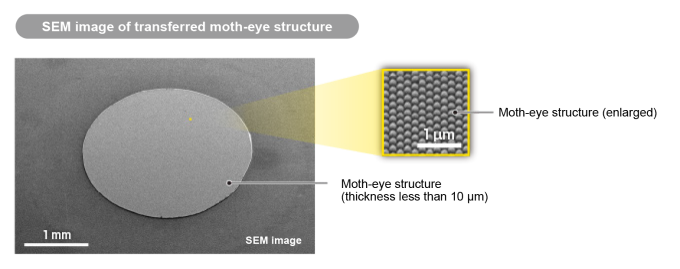

The electron microscope image below shows a moth-eye structure transferred to a glass plate using substrate-free microstructure transfer technology. The round shape in the middle is the moth-eye structure, with a thickness of less than 10 µm.

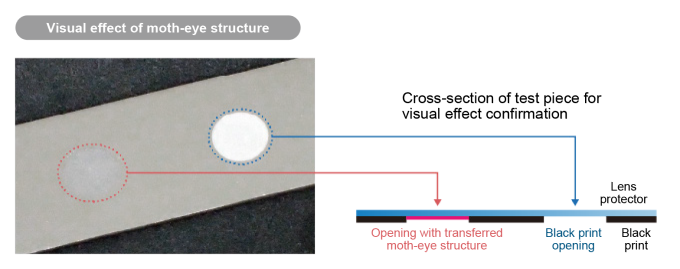

The visual effect of a moth-eye structure transferred with substrate-free transfer technology can be seen in the image below. The round area in the blue dotted circle reflects fluorescent light from the ceiling and appears white. The red dotted circle on the left with a transferred moth-eye structure, on the other hand, reflects very little light. As a result, the color of the black sheet below can be seen, making it difficult to make out the border between the moth-eye structure and the black print under the glass.

Greater transparency from the substrate-free structure

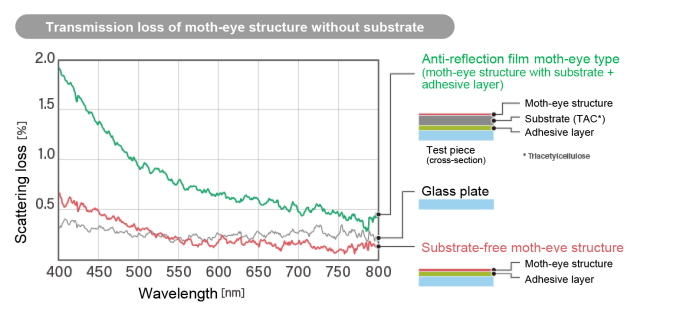

The graph below compares transparency between a conventional film-type moth-eye structure (moth-eye structure with substrate) and a substrate-free moth-eye structure. The vertical axis shows haze (light scattering) and the horizontal axis shows wavelength. The moth-eye structure with substrate, shown in green, shows lower transparency due to the slight light scattering caused by the substrate (TAC*) and adhesive layer between the adherend and moth-eye structure. In comparison, the substrate-free moth-eye structure shown in red shows the same level of transparency as glass with nothing applied (shown in gray) across all wavelengths.

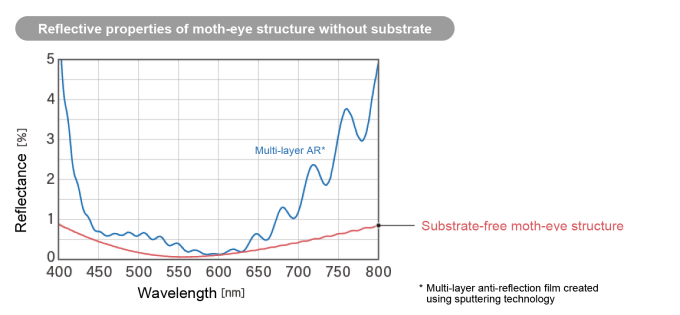

Wide-spectrum low reflectance, handles angle changes well

The graph below, with reflectance on the vertical axis and light wavelength on the horizontal axis, shows the color-related optical properties of anti-reflection film (multi-layer AR) using sputtering technology and substrate-free moth-eye structure. It indicates that multi-layer AR has high reflectance in wavelength ranges of 450 nm and below (blue light) and 650 nm and above (red light). Substrate-free moth-eye structure, on the other hand, reflects less light across a wide spectrum.

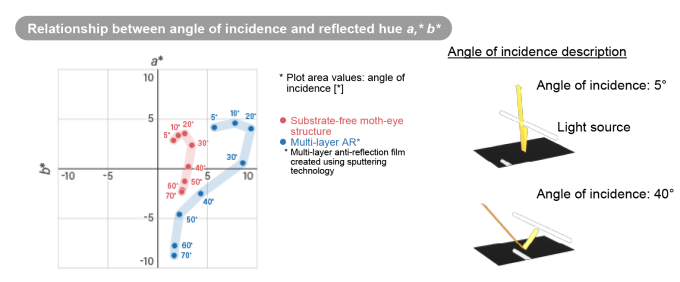

This graph plots the angle from which the film is viewed on the vertical axis and the rate of color change on the horizontal axis. The closer a point is to the origin in the center, the less the color changes. Most of the substrate-free moth-eye structure’s points are near the origin, with little color change regardless of the viewing angle. But for multi-layer AR, a more diagonal viewing angle results in more added color.

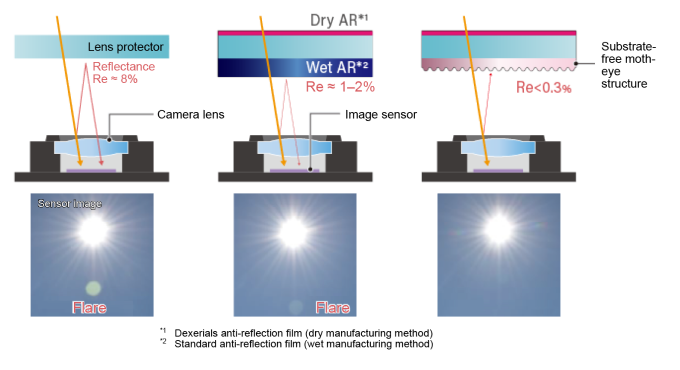

Reducing flare through application to lens protectors

One promising application of substrate-free transfer of moth-eye structures is in lens protectors for surveillance cameras and doorbell cameras. Since these are fixed-position cameras, the effects of changing sunlight over time are unavoidable. When recording a bright scene, flare can occur if incident light reflects off the surface of the lens and then reflects again off the lens protector. Applying anti-reflection film or transferring a moth-eye structure to the lens protector can be effective ways to prevent this. The photographs below show flare with no countermeasures on the left (8% reflectance), with conventional anti-reflection film in the center (1–2%), and with moth-eye structure transferred to the lens protector on the right (0.3% or below). Flare can be seen clearly on the left and is still slightly visible in the center, but cannot be seen at all with substrate-free moth-eye structure on the right.

By eliminating the substrate, substrate-free microstructure transfer technology reduces scattering, enhances transparency, and can be applied anywhere using adhesives. We expect the various cameras installed on an increasing variety of devices and optical sensors on vehicles will be a primary area where the technology can be applied. Please look forward to the full industrial application of this newly completed technology.

- SHARE

Back to top

Back to top  Contact us

Contact us