- Bonding Products

The secret of ArrayFIX, particle-arrayed ACF

目次

The story behind the angled ArrayFIX logo

ArrayFIX, a particle-arrayed Anisotropic Conductive Film (ACF), was launched by Dexerials in 2016. Conductive particles are dispersed and uniformly aligned in a thermoset resin. The alignment of the conductive particles ensures stable pad connections and reduces the risk of short circuits between pads.

On the ArrayFIX logo, the letters are slanted slightly to the right by 15°. This article describes the features of the latest ArrayFIX product.

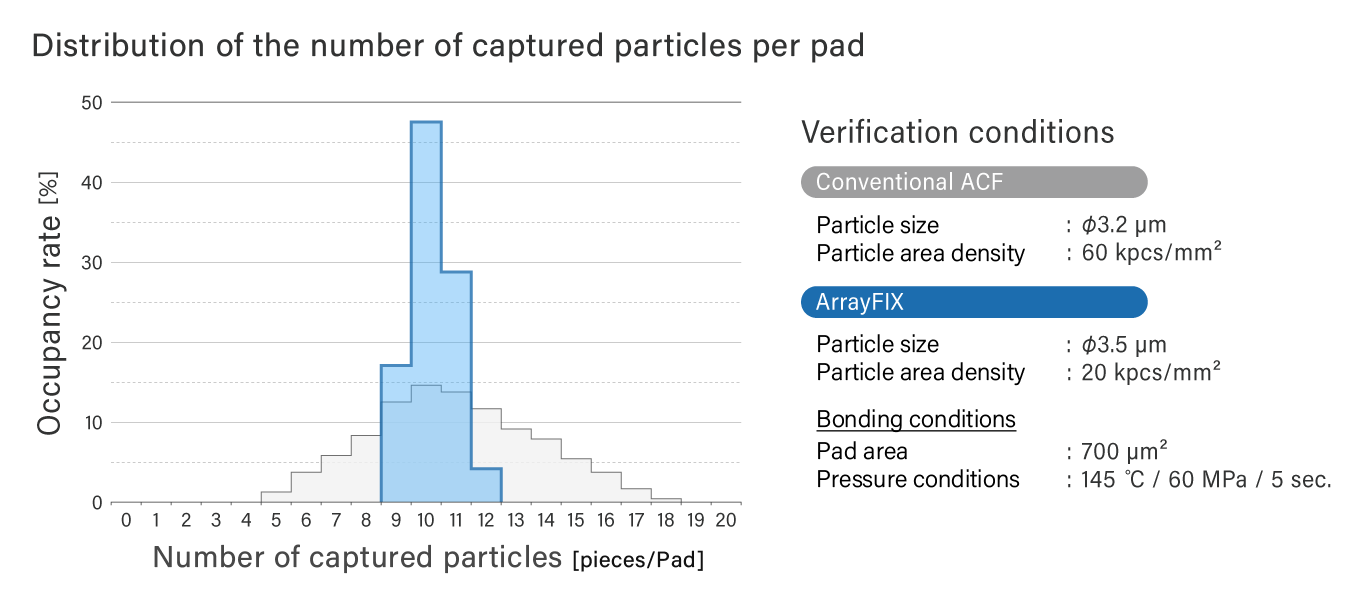

The graph below shows the distribution of the number of captured particles a pad during COG (Chip on Glass) bonding. In conventional ACF, the number of captured particles reflects a normal distribution pattern, varying from 4 to 18. In comparison, the number of captured particles with ArrayFIX is extremely stable, ranging from 9 to 12.

Using a 15° angle to achieve stable connections

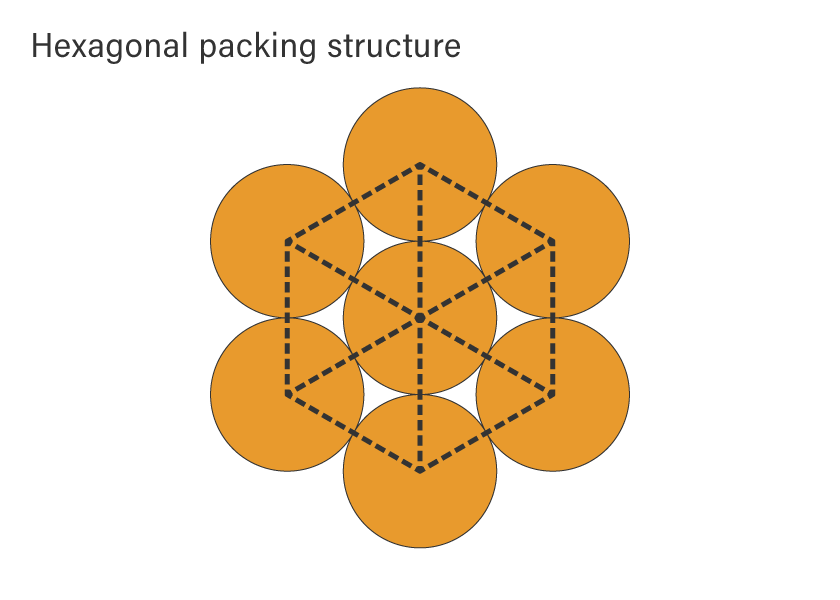

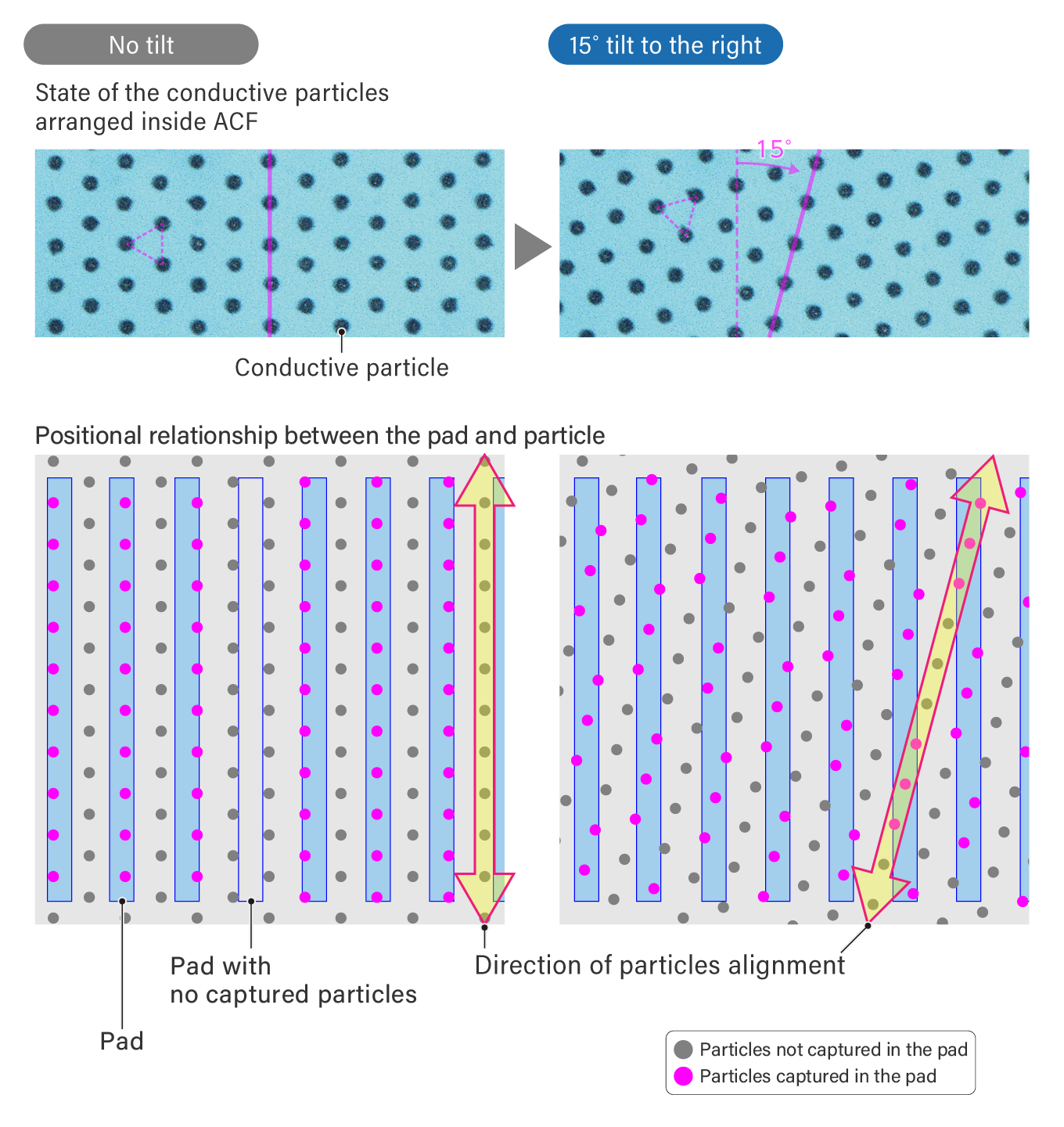

A major reason for stable connections of ArrayFIX is the angle of the aligned particles. The arrangement that most efficiently captures aligned conductive particles in a pad is the hexagonal packing configuration, shown in the figure below.

When ArrayFIX was first being developed, the particles were aligned in a hexagonal packing shape. The particles were arranged parallel (0° angle) to the longitudinal direction of the pad, as shown in the left of the figure below. However, when particles were aligned parallel to the pad, there was a possibility that the pad would not capture any particles.

To solve this problem, Dexerials chose to tilt the particle arrangement by 15° with respect to the pad, as shown in the figure on the right below. The 15° angle ensures that the pads will always capture the particles. As a result, the ArrayFIX design has always included this 15° angle since its launch in 2016.

ArrayFIX’s latest “cascade design”

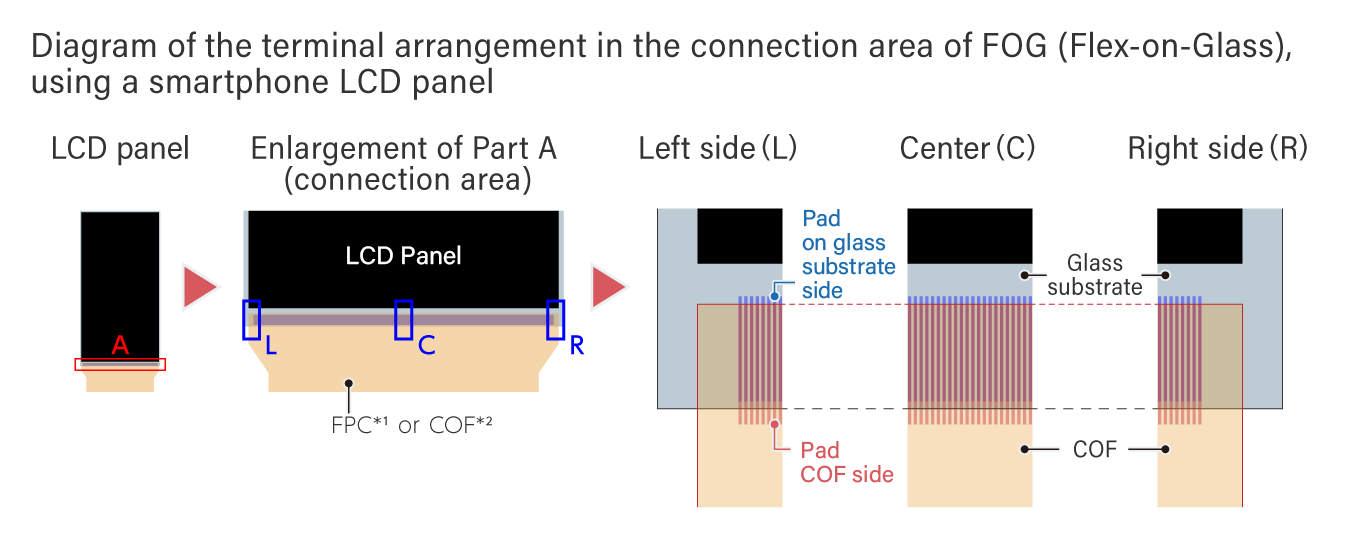

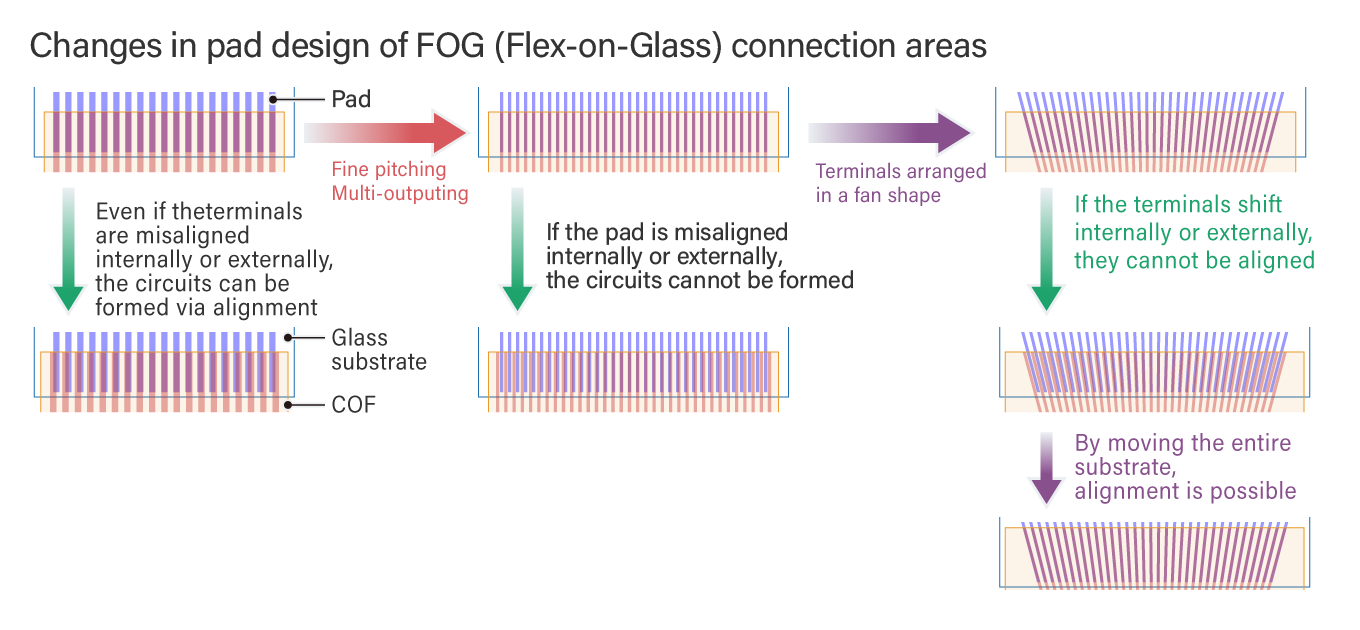

Recently, ArrayFIX was further modified. For FOG (Film on Glass) display connections, there is a demand for finer pitch connections with smaller connection areas. Pads with a width of less than 10 microns are now common, making it difficult to align the pads on each circuit board.

In the ACF bonding process, a camera on the bonding machine is used to align the board. However, since the pad width is very small, it can take time to adjust the position to minimize misalignment. In the worst case, the machine may temporarily halt due to the time it takes to calculate such small adjustments. To avoid this issue, Dexerials began using a fan-shaped board, as shown below.

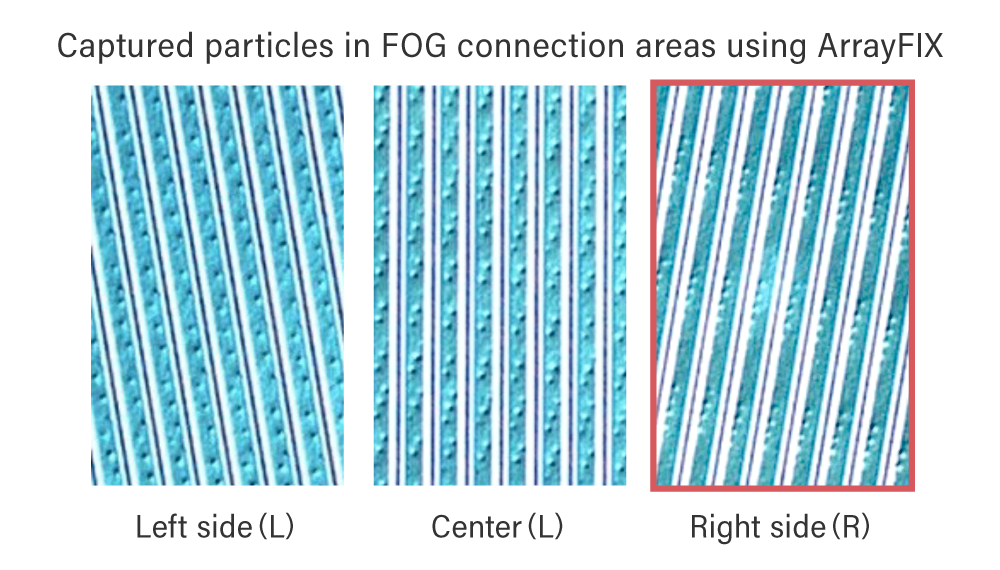

If the pads are arranged in a fan shape, the connection pads will have different angles from the left, right and center of the board, as shown below. Although the state (appearance) of the captured particles is different on the left and the right side with the center as the base axis, there is not much difference in the number of conductive particles captured on both sides. Dexerials developed a cascade design in response to a customer’s request for the same appearance of captured particles on the left and right sides.

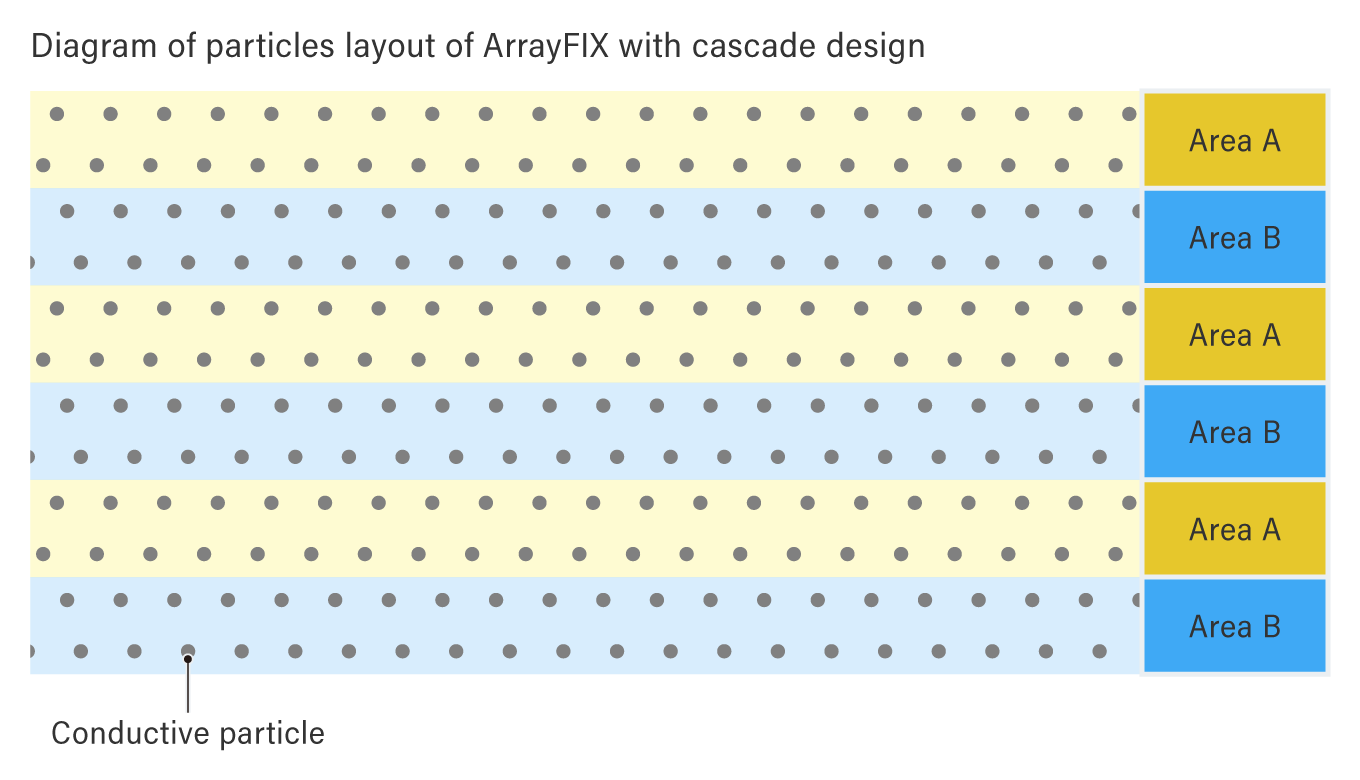

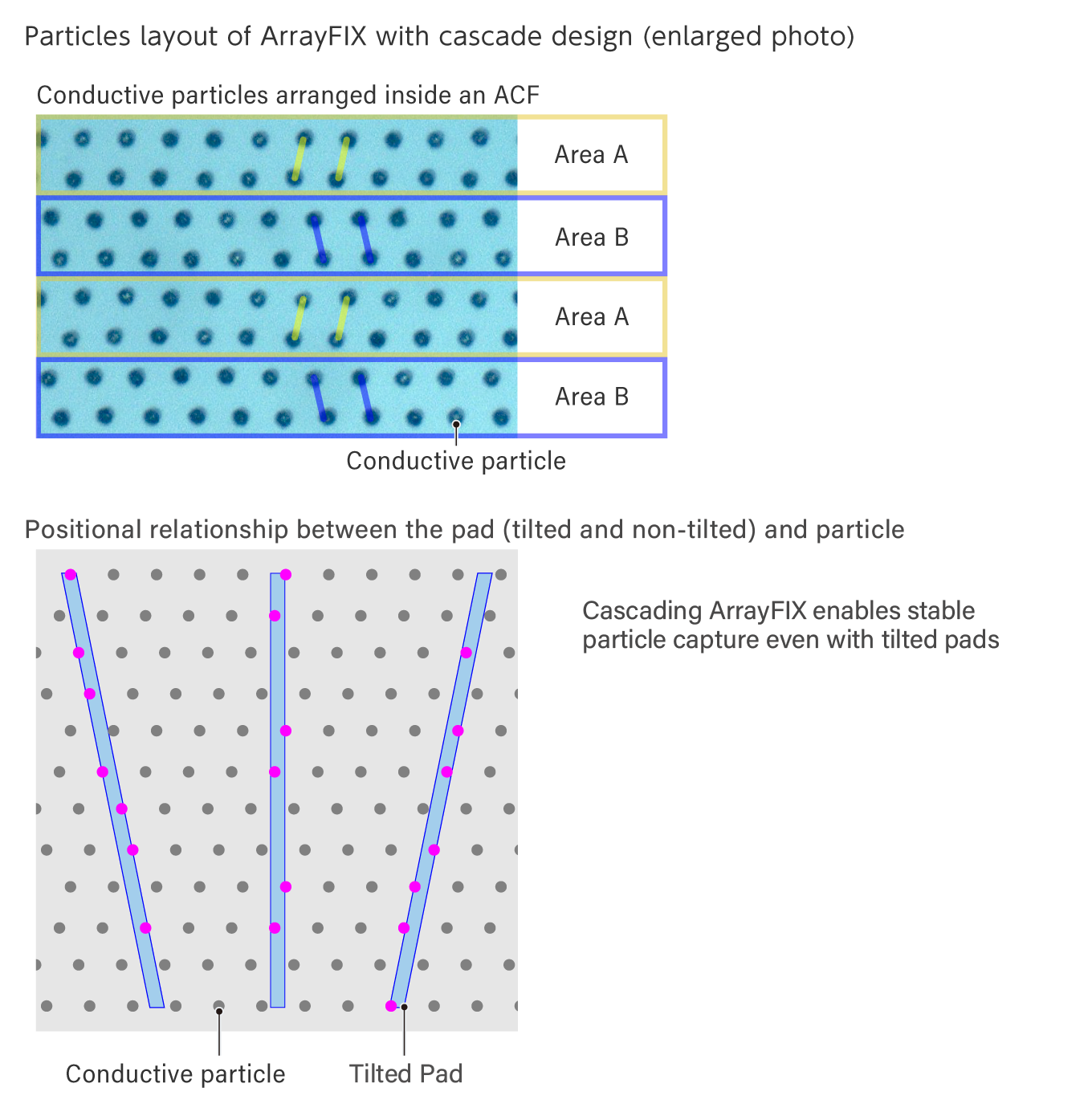

The cascade structure is one in which the same structures are arranged alternately. The particle layout of Dexerials’ newly developed cascading ArrayFIX is shown below. Tilted particles are alternated in Area A and B. This enables stable connections even when the angle of the pads changes.

Below is a diagram of the bonded pads using a cascading ArrayFIX. The center pad and both the tilted left and right pads capture particles evenly.

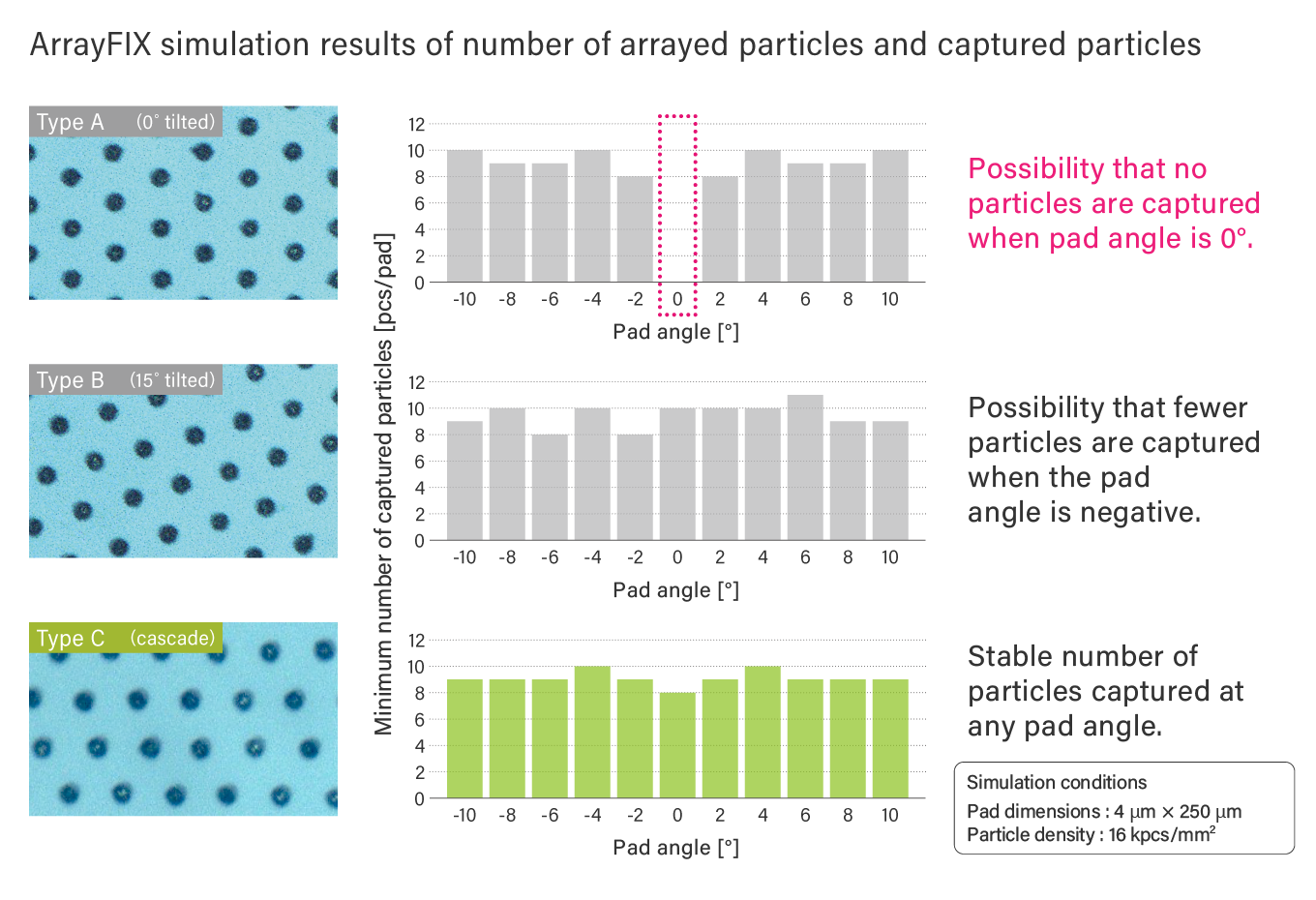

The following images and graphs show the minimum number of particles captured at varying pad angles for three types of ArrayFIX: Type A (0° tilt), Type B (15° tilt), and Type C (cascade design). With Type A connection, there is a possibility that no particles are captured when the pad angle is 0° (the particles alignment and pads are parallel). In contrast, with Type B and Type C connections, the number of captured particles remains stable even when the pads are at an angle.

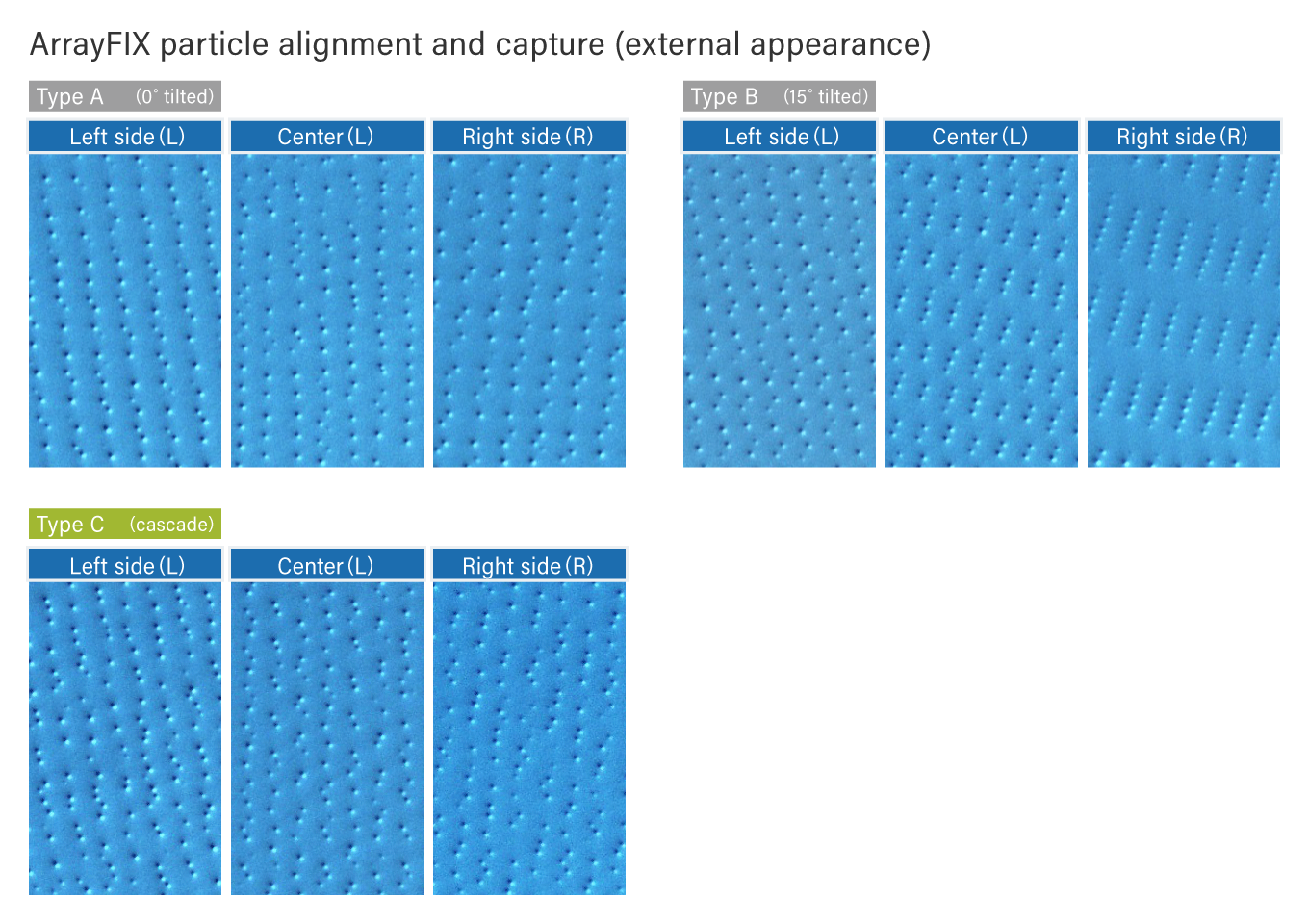

Below images show the state of captured particles. In Type B, the appearance of captured particles on the left and right side are very different. Meanwhile, in Type C (cascade design), all the pads on the left, center, and right sides capture particles in the same way. The cascade design enables stable particle capturing and improves the appearance in the aforementioned customer request.

Positioning of particles helps realize new ideas

The cascading ArrayFIX is a unique product developed by Dexerials utilizing advanced design and processing technologies. Not only does it uniformly align the small particles in thermosetting resin, but it also arranges them at targeted positions.

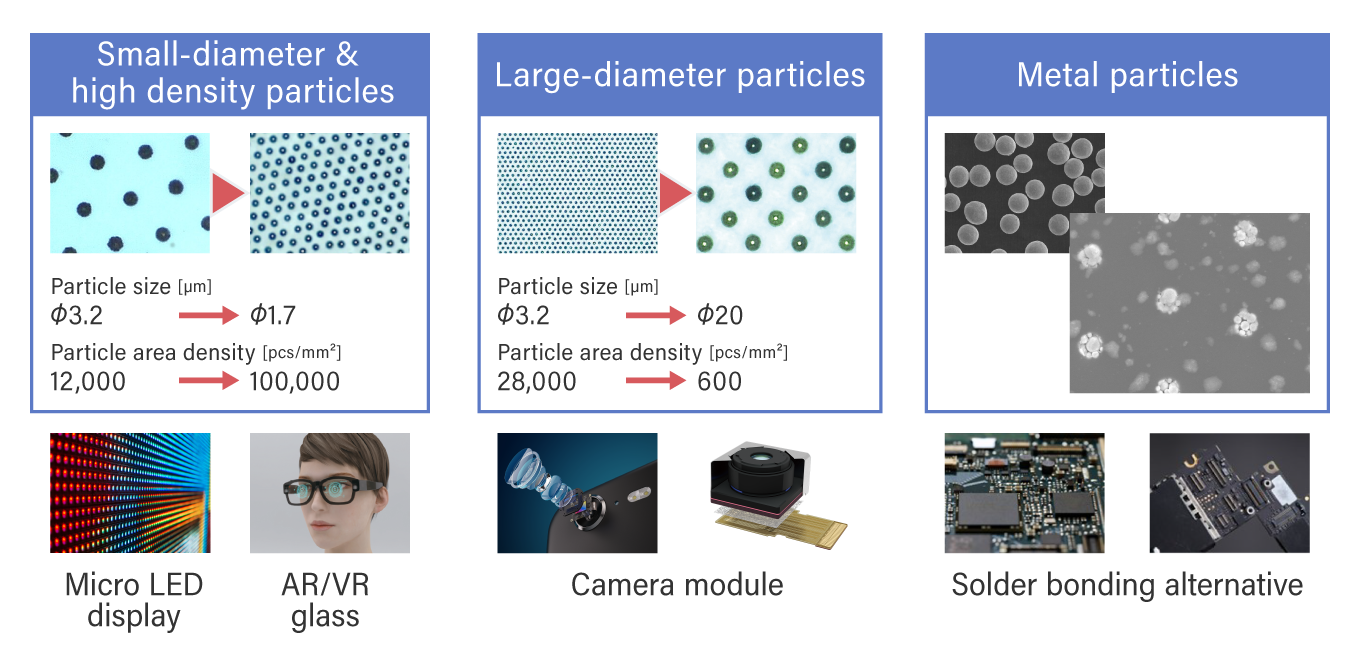

Dexerials will continue to improve ArrayFIX to meet customers’ demand and to find new applications. Such applications may include but are not limited to micro-LED displays, AR/VR glasses, and smartphone camera modules. Dexerials is also considering the development a new ArrayFIX that use metal particles to replace solder for bonding electronic components. The future holds ever-expanding possibilities for ArrayFIX.

ArrayFIX and its logo are registered trademarks of Dexerials Corporation in Japan and in other countries.

Related articles

私たちデクセリアルズはデバイスの進化に欠かせない材料や次世代のソリューションを生み出す、マテリアルメーカーです。

電子部品、接合材料、光学材料をはじめと世界中のパートナーと新しい価値を生み出していきます。

- Share

We provide materials on our products and manufacturing technologies.

They can be downloaded for free.

Download Materials

We provide materials on our products and manufacturing technologies.

They can be downloaded for free.

Download Materials