- Bonding Products

Low-Dielectric Thermosetting tape for the 6G Era: Support for Development of Internal Components of Smartphones

Contents

Development of internal smartphone components that support millimeter waves

Fifth-generation(5G) smartphones currently in use have problems such as slow construction of millimeter-wave (28 GHz) communications infrastructure and short communication ranges. As such, bands under 6 GHz, known as Sub 6, are mainly used because of their usability. Considering an increase in traffic over the coming years, however, a transition to millimeter-wave (28 GHz) bands is considered inevitable. In addition, the implementation of 6G communications that use sub-terahertz waves between 90 and 300 GHz and extremely high frequency bands around 3 THz is expected to begin around 2030.

This article introduces a technology for adopting FPC as circuit boards for high-frequency antennas inside smartphones and another related key technology for reducing transmission loss. This article concludes with a description of Dexerials’ low-dielectric thermosetting tape, developed specifically for this advancement.

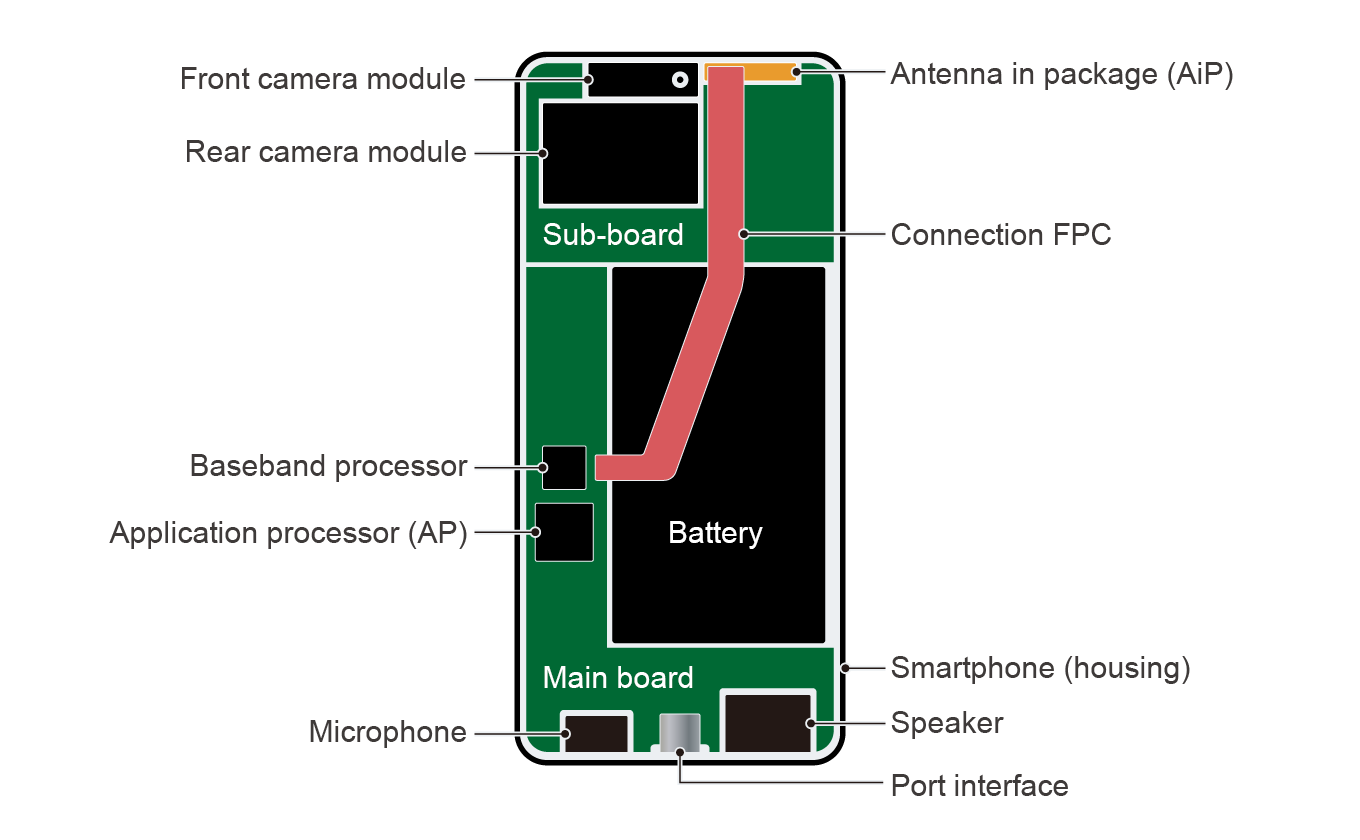

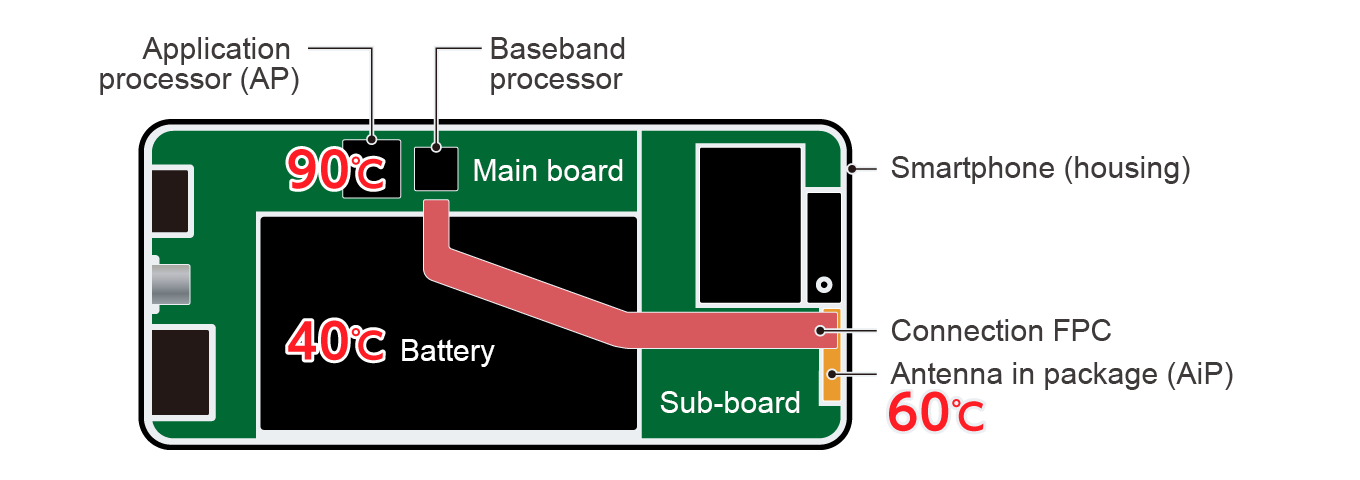

The following image illustrates the internal components of a new smartphone model available in stores this year (2023). A thermosetting tape with low-dielectric properties is used in the component labeled “connection FPC,” which is indicated in red. The connection FPC board refers to the wiring circuit board, which connects the “antenna-in-package” (AiP) component that receives 5G millimeter-wave radio signals (indicated in yellow), to the main circuit board that performs calculations based on the received radio signals. The connection FPC board is used not only to send the externally-received downstream signals to the main circuit board, but also to relay the processed signals from the main circuit board to the AiP. From there, these upstream signals are transmitted from the antenna.

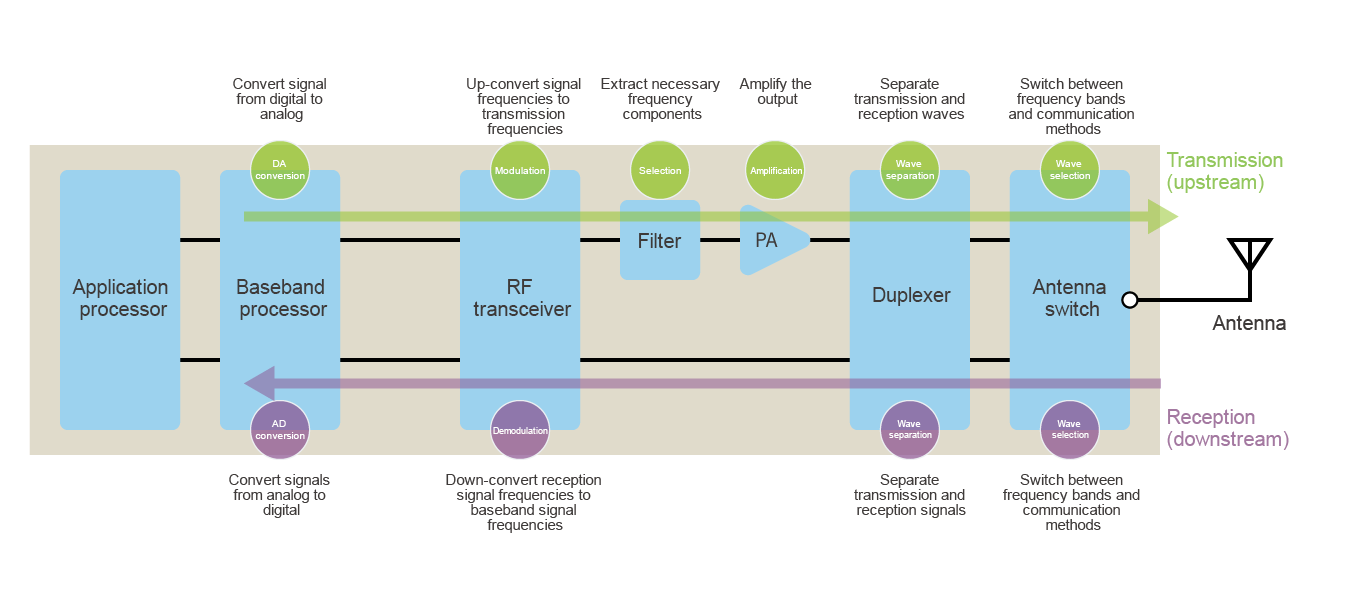

The following diagram illustrates the communication components of a smartphone and the transmission and receipt processing flow. The leftmost component is an IC chip known as the “application processor(AP),” which is essentially the brain of a smartphone and is equivalent to a PC’s CPU. The rightmost component is the antenna, where signals are sent and received.

The first topic to cover is the components. The application and baseband processors in the left part of the following diagram are mounted on the larger printed circuit board known as the main board. The previously mentioned AiP (antenna in package) comprises multiple components, including the RF transceiver, which modulates signal waves, and the antenna. Normally, the antenna is mounted near the exterior of the housing and separated from the main board for efficient transmission and reception of signals. The electric circuits of these components are interconnected using a connection FPC board. It can be longer than half the length of the long side of the housing depending on the design of the smartphone.

_E.png)

An AiP for the millimeter-wave band (28 GHz) is taken as an example here for illustration purposes. At the moment, the connection FPC board relays analog signals at frequencies of 8 to 10 GHz. The RF transceiver embedded in the AiP performs frequency conversions, namely up-converting when sending signals (upstream) and down-converting when receiving signals (downstream). This is because 28-GHz electric signals are prone to attenuation and loss along transmission paths.

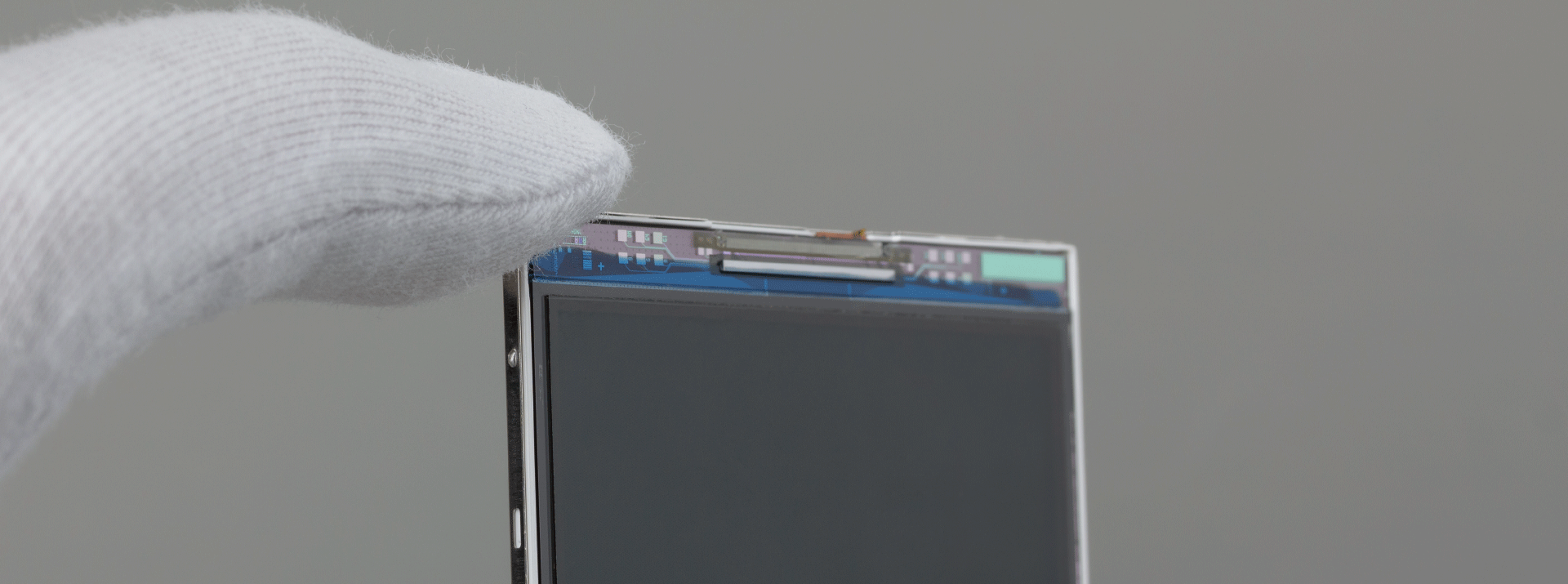

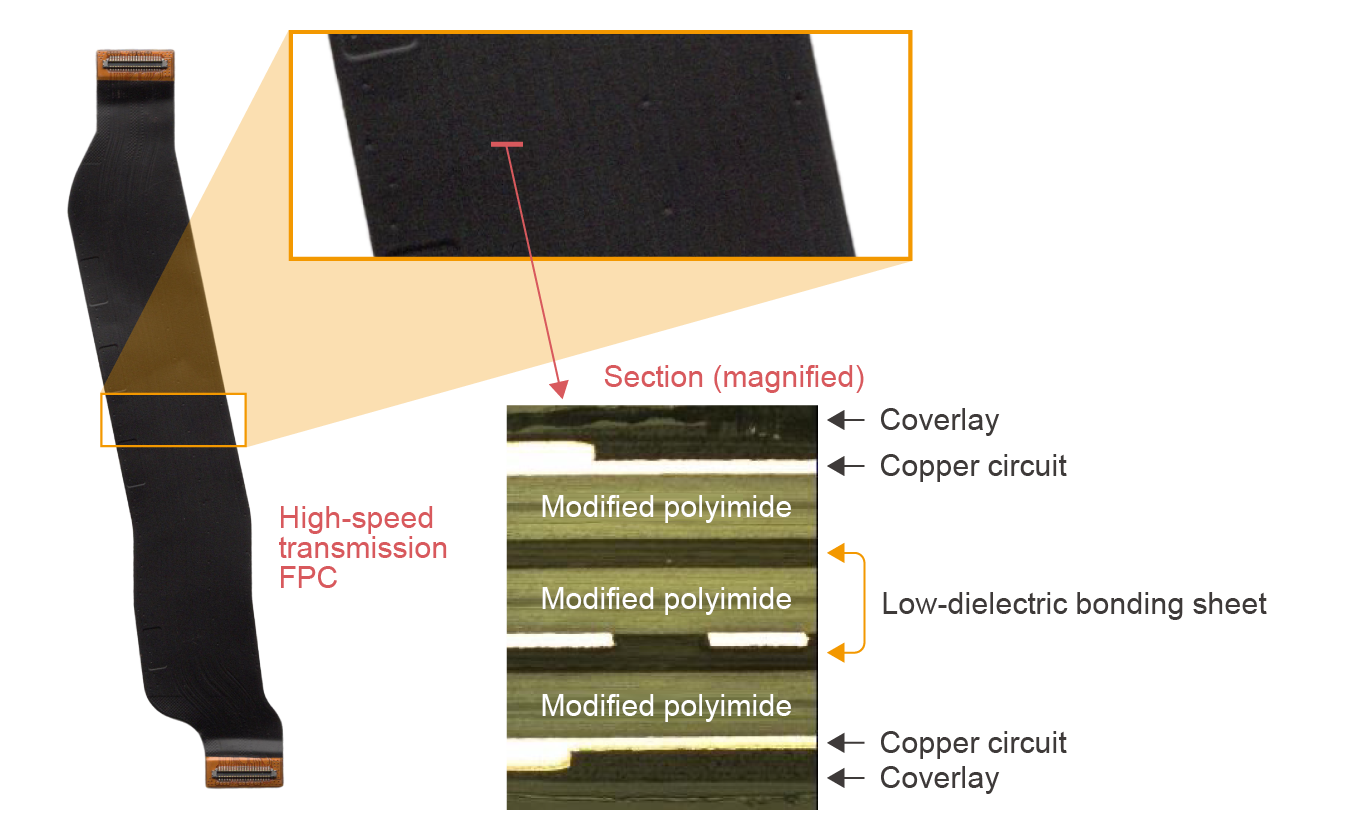

The following image shows a section of a connection FPC board that uses our low-dielectric thermosetting tape. Dexerials’ D5300 series of low-dielectric thermosetting tapes is used between the modified polyimide (PI) layers.

FPC as a 28-GHz antenna

The following diagram illustrates the technology expected to be used for smartphones starting from the latter half of 2023. The millimeter waves received by the antenna are sent from the AiP to the main board through the FPC board, at the original 28 GHz frequency. Upstream signals from the main board are also transmitted at the high frequency of 28 GHz. Achieving this mechanism requires that attenuation of high-frequency analog signals at the connectors and in the connection FPC board is minimized. Exchanging signals at the original 28 GHz frequency instead of the down-converted 8 GHz frequency simplifies processing on the antenna side, which in turn makes it possible to streamline and integrate the functions and increase processing speed (see the figure below). As such, various research efforts are underway to realize this mechanism.

_E-1.png)

Some are making attempts to further evolve this mechanism to adopt a FPC board as an antenna board. Currently, a smartphone antenna is manufactured by etching or printing a metal line pattern that functions as an antenna on a rigid or ceramic board. The idea described above involves replacing that solid rigid or ceramic board with a thin, bendable FPC board and using it as an antenna. FPC boards cost less than rigid and ceramic boards, and are also considered to contribute to manufacturing thinner smartphones.

To use FPC boards as millimeter-wave antenna boards, it is necessary to develop FPC boards capable of supporting 28-GHz signals. Consequently, the thermosetting tapes integrated into FPC boards must also possess low-dielectric properties to support millimeter-wave frequencies. For details on the low-dielectric properties of thermosetting tapes, this article is recommended.

Anti-heat measures: key challenge for millimeter-wave bands in smartphones

The following image illustrates the internal components of a currently available model of smartphone. Components that require higher heat resistance are labeled in yellow, with their target temperatures indicated in red.

The application processor (AP) is the IC chip responsible for information processing in a smartphone. Its temperature can reach approximately 90°C during intense processing, which in turn thermally affects its surrounding components. In addition, many smartphones are designed to keep the temperatures of the AiP and the battery below approximately 60°C and 40°C, respectively.

As described above, it is certain that upcoming smartphones will use millimeter-wave bands, which poses the challenge of increased temperatures within the smartphone housings. The addition of more heat-generating components, such as the AiP and signal processing IC chips, tends to increase the internal temperature of a smartphone.

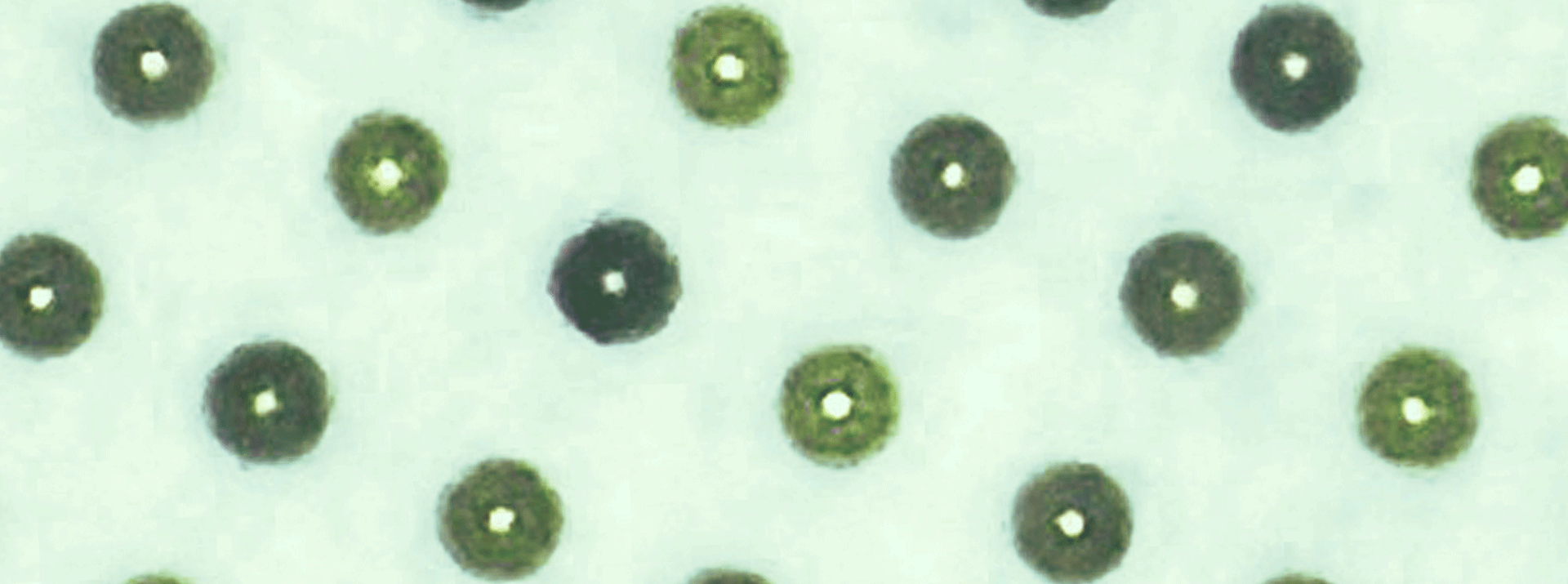

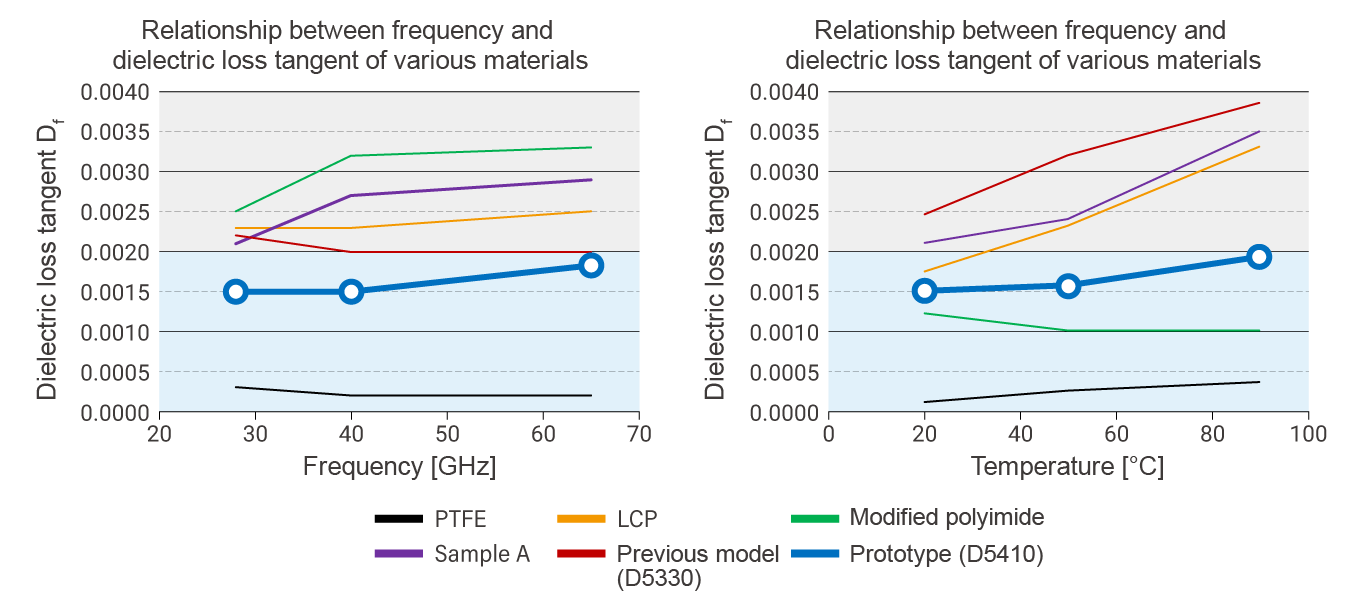

The rise in internal temperature also leads to an increase in the temperatures of the modified polyimide and other plastics used in FPC boards. Typically, the dielectric loss tangent of a plastic is known to degrade as its temperature increases, as shown in the graph on the right side of the following image. This can result in delayed signal transmission in circuit boards, including FPC boards.

For this reason, it is ideal to use FPC boards made of insulating materials for circuit boards handling high-frequency signals. These materials maintain consistent dielectric loss tangents even at increased temperatures, thereby preventing signal loss.

Low-dielectric thermosetting tape: underpinning the future of smartphones

Dexerials estimate an increased utilization of higher frequency signals in FPC boards. This shift is due to the design changes that allow signal transmission through FPC boards without the need for down-converting frequencies, and the ongoing research of using FPC boards as antennas, as detailed above. In addition, the temperatures of FPC boards themselves may increase due to the addition of heat sources inside smartphones. Consequently, we are confident that there is a demand for thermosetting tapes that maintain stable low-dielectric properties even under conditions of high frequencies and elevated temperatures.

The following charts show the dielectric characteristics (dielectric loss tangents) of various insulating materials. The red line indicates our Thermosetting tape available on the market (model number: D5330), and the blue line indicates our soon-to-be-launched prototype. The left chart indicates the relationship between dielectric loss tangents and frequencies. Dexerials’ target is a dielectric loss tangent of Df < 0.002, which is superior to that of a liquid-crystal polymer (LCP). Whereas our previous model (D5330) barely misses the target range, our prototype successfully falls within it. The right chart indicates the relationship between dielectric loss tangents and environmental temperatures. Our prototype falls within the target range at and below a temperature of 90°C and also keeps variations low.

Our low-dielectric Thermosetting tape can be cost-effectively bonded to layers of liquid polymers and modified polyimide, or the key materials of fast-transmission FPC boards. Consequently, it enables the manufacturing of FPC boards capable of supporting 5G (millimeter-wave) signals using existing manufacturing equipment (for details, please refer to this article). Stay updated on Dexerials’ product development, which aims to meet the needs of all customers, including smartphone manufacturers, in anticipation of the upcoming 6G era.

- SHARE

Back to top

Back to top  Contact us

Contact us