- Bonding Products

Dexerials’ Inspection Process for Anisotropic Conductive Film

Contents

Inspection capabilities

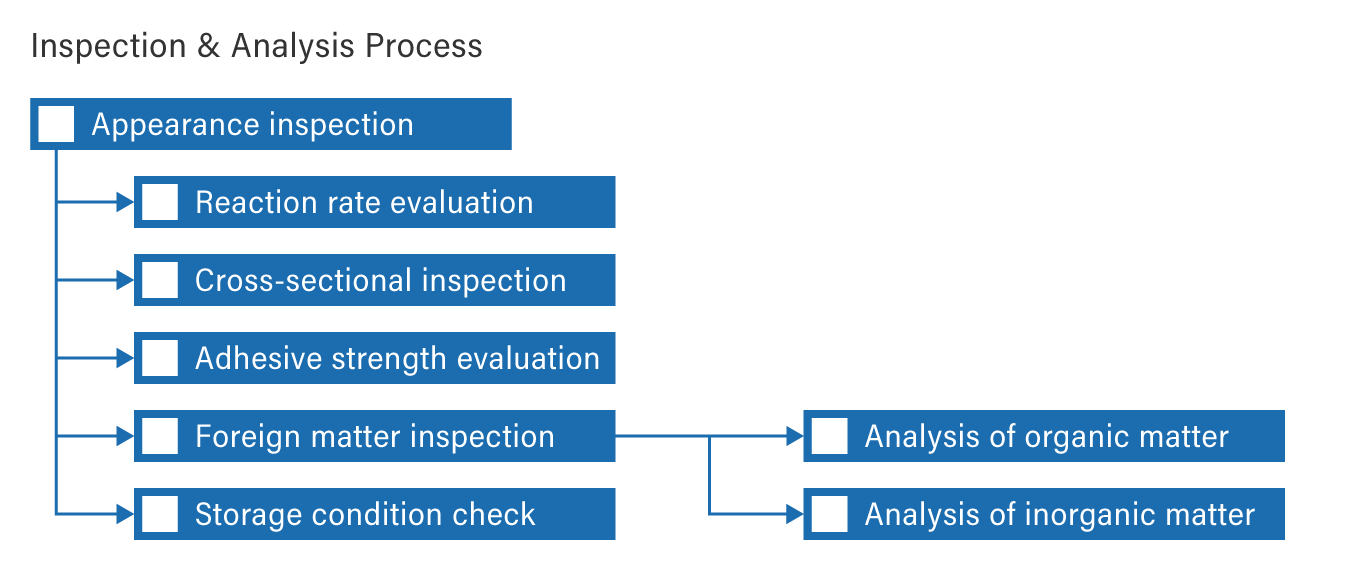

The following diagram describes the inspection and analysis process that Dexerials uses for Anisotropic Conductive Films (ACFs). Each step is explained in detail below.

Appearance inspection

First, Dexerials conducts an overall check to ensure that there are no abnormalities in the external appearance of the film. The condition of the external appearance provides important information for the subsequent inspection process. For ACFs that have not yet gone through the crimping process, abnormalities such as air bubbles, peeling of the protective film, or deterioration are checked. Crimped samples are observed from various angles using a metallurgical microscope. They are inspected to see if there are any voids in the ACF resin, if foreign substances are mixed in, if the indentation and dispersion of conductive particles meet the standard. After the appearance inspection, the team puts together an inspection plan to determine the root cause of any abnormality and provide a solution to any issues.

Reaction rate evaluation

Measuring the reaction rate is a basic step in the adhesive inspection process. This step confirms whether the ACF was properly bonded by applying heat and pressure. There are epoxy and acrylic types of thermosetting resins used for ACFs. In both cases, Dexerials determines whether the curing reaction occurs as expected by measuring the absorption rate of infrared rays using a Fourier transform infrared spectrophotometer (FT-IR). If the reaction rate is less than expected, it means that there was not enough thermal energy required to cure the resin.

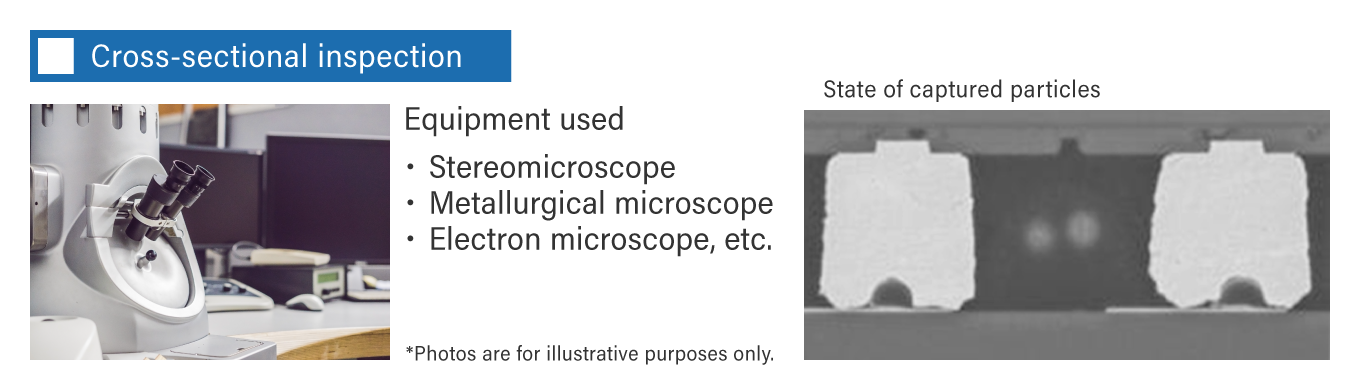

Cross-sectional inspection

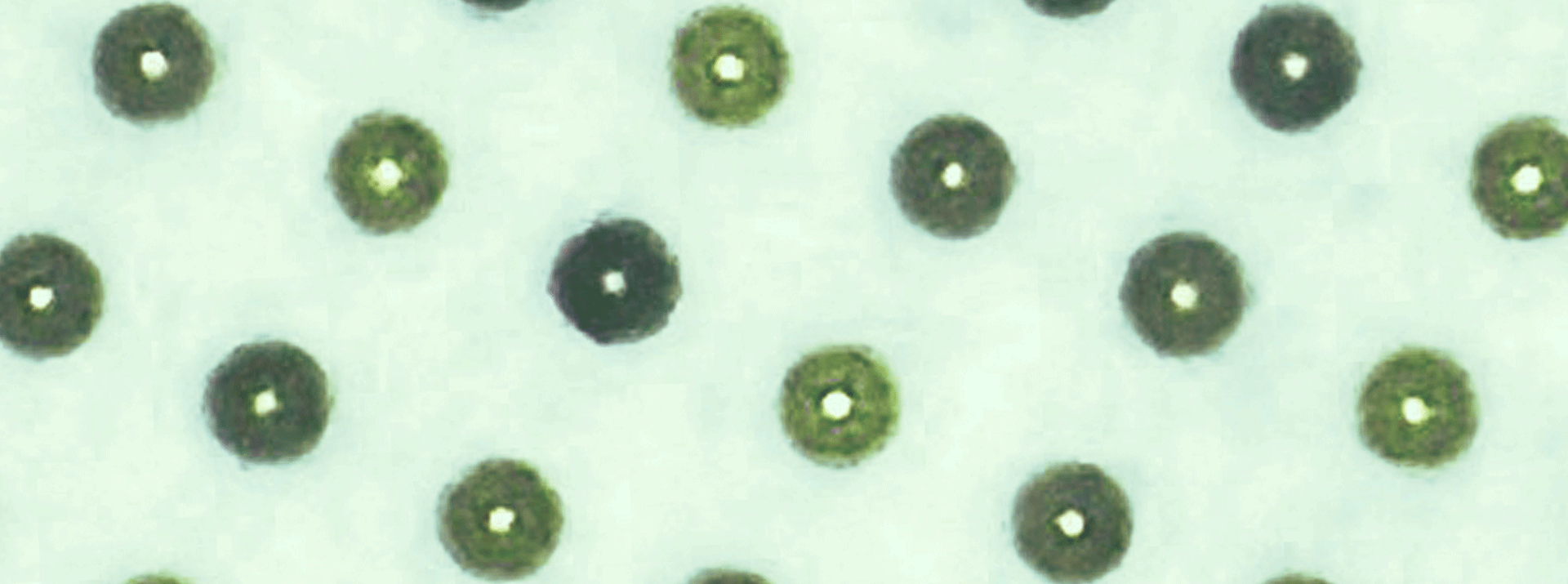

The main purpose of the cross-sectional inspection is to check the state of the pad connections. The area connected to the pad via conductive particles is carefully shaved with a grinder to determine the state of the conductive particles in the cross section. Dexerials also verifies that the particles sandwiched between the pads and substrate are deformed and conductive, and that the particles between the pads remain insulated. Accurate and careful cross-sectional cutting skills are required as the latest ACFs have particle diameter of 3 microns or less.

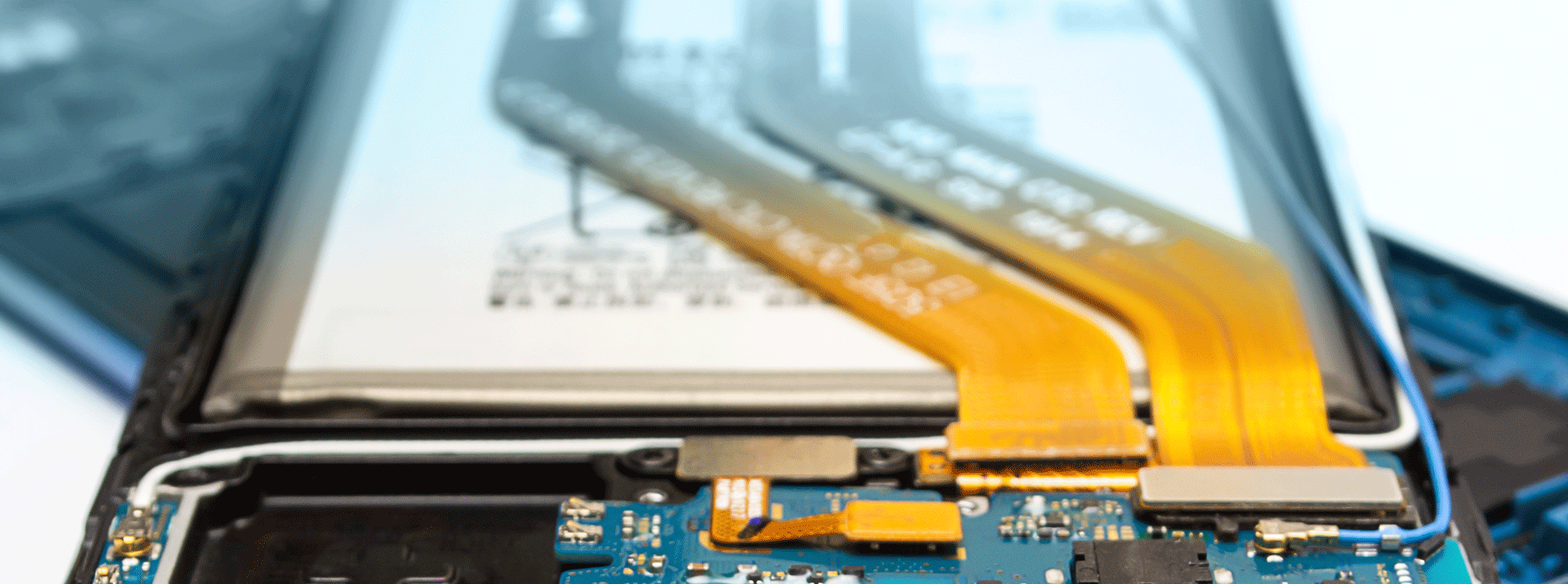

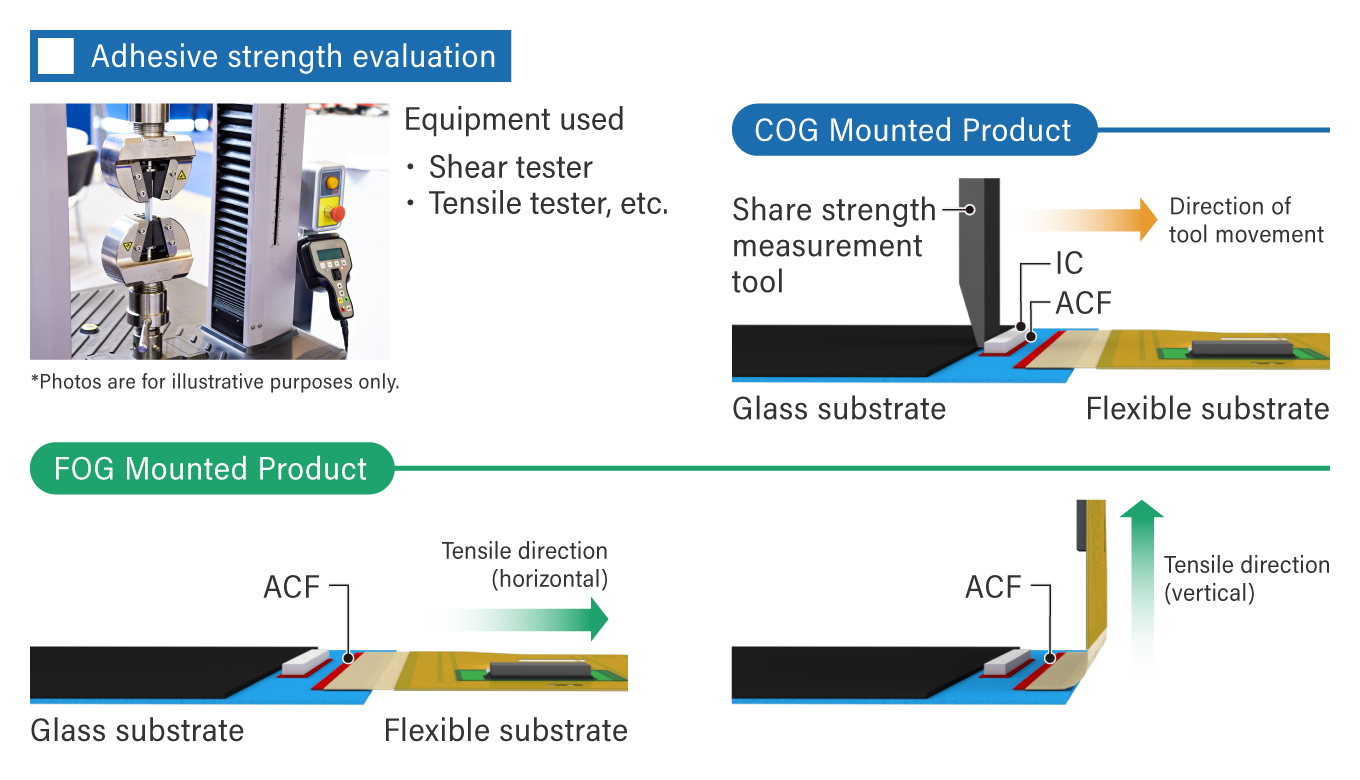

Adhesive strength evaluation

Dexerials measures the adhesive strength to confirm that ACF is properly bonding the components. For COG (Chip on Glass) mounting, where ICs (integrated circuits) are connected to glass substrates, the adhesive force is measured horizontally (shear direction). For FOG (Film on Glass) mounting, where flexible printed circuits are connected to glass substrates, the force is measured in both the horizontal and vertical directions. Dexerials also conducts a test to understand under what conditions the adhesion fails and uses these results, together with the adhesive strength test, to determine the root cause of failure.

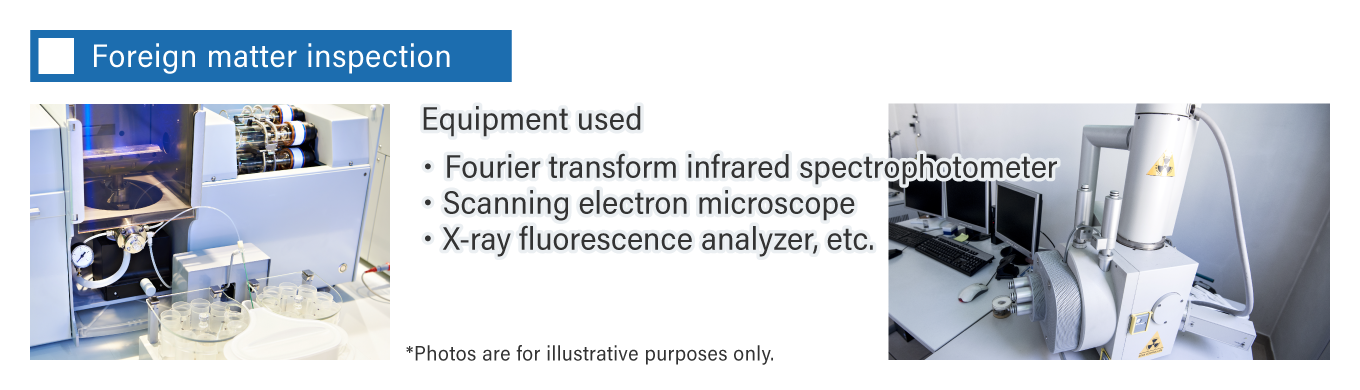

Foreign matter inspection

The most common problem that occurs after bonding, not only for ACFs but also other adhesive materials, is contamination by foreign matter. There are different types of foreign substances, organic and inorganic. Dexerials analyzes organic contaminants using Fourier transform infrared spectrophotometers (FT-IR), and inorganic contaminants using scanning electron microscopes (SEM) and X-ray fluorescence analyzer (EDX). By clarifying the composition of foreign substances, the origin of contamination can be determined and tracked to solve the quality issue.

Storage condition check

Thermosetting ACFs are adhesive films that undergo a curing reaction simply by being left at room temperature. Therefore, it is necessary to store ACFs under the specified temperature before use. Proper storage will ensure that the films function properly. If there are any issues during the storage process at the customer location, Dexerials can help establish an optimal product management system to prevent product failures or quality problems.

Preventing problems and resolving them quickly

There is always some cause for defects in any product, not just ACFs. As described above, problems may occur due to a defect in the ACF, storage conditions, manufacturing equipment or process. Dexerials has the capability and knowledge to provide solutions to problems associated with the use of ACFs and look forward to working with the customer on any matters related to ACFs application.

- SHARE

Back to top

Back to top  Contact us

Contact us