- Bonding Products

The value-added ArrayFIX, a particle-arrayed ACF

Contents

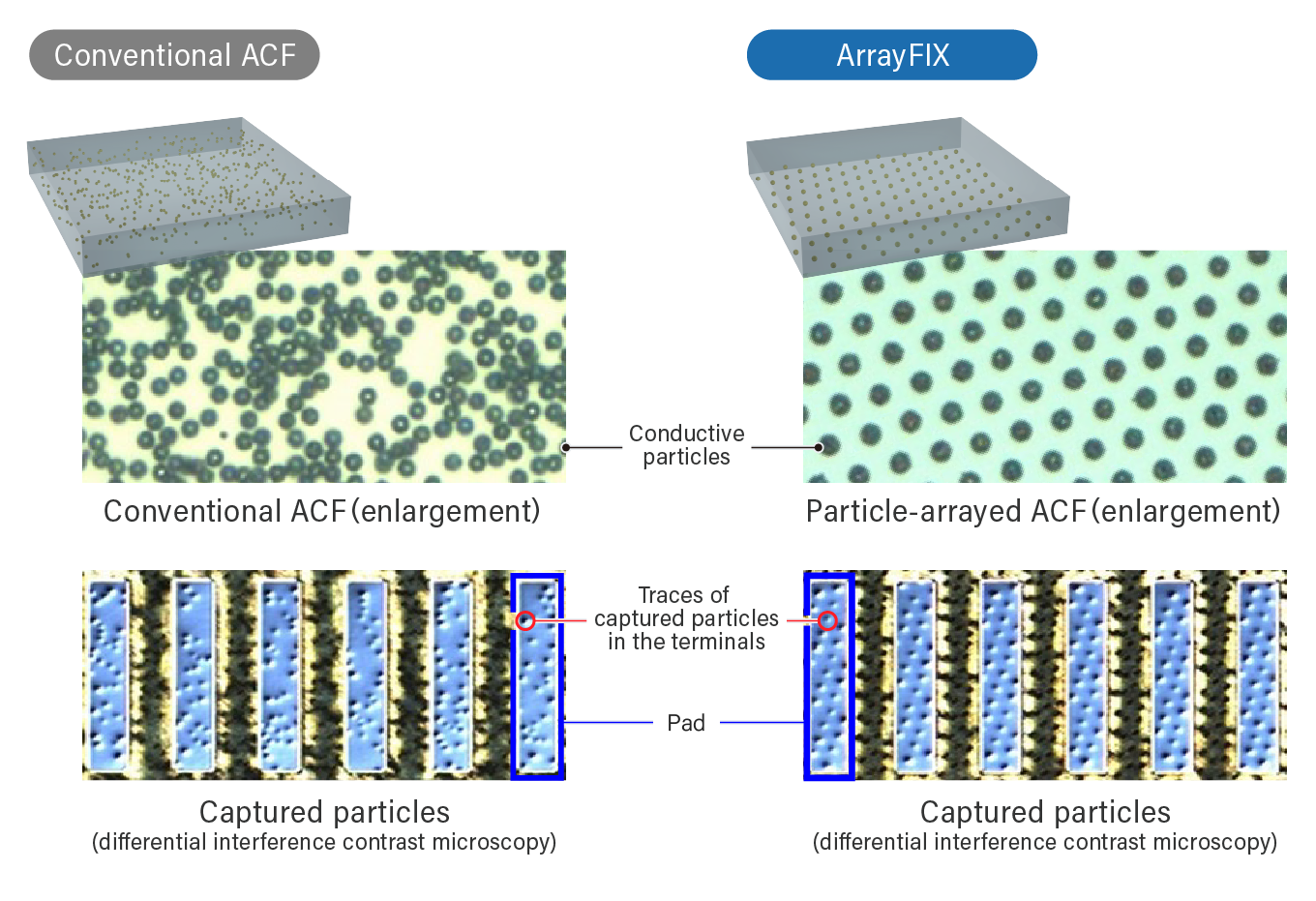

ArrayFIX captures particles for reliable connection

ArrayFIX is a particle-arrayed anisotropic conductive film (ACF) developed by Dexerials in 2016. Compared to conventional ACFs with randomly dispersed particles, conductive particles in ArrayFix are arrayed uniformly inside a thermosetting resin. Arranging the conductive particles ensures stable pad connections and reduces the risk of short circuits between pads.

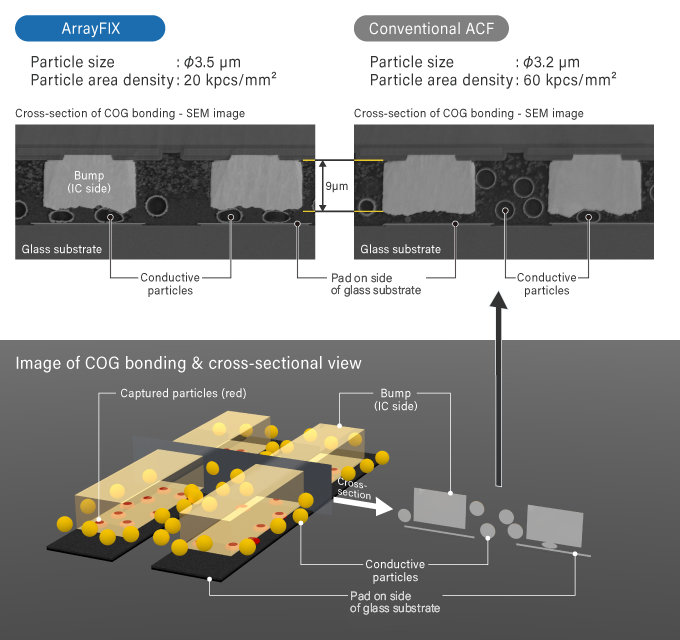

The electron micrograph below shows a cross-sectional view of pads during COG (Chip on Glass) bonding, the process in which an IC chip is connected to a glass substrate, using both ArrayFIX and conventional ACF. The particles visible between the left and right IC pads (bumps) are noteworthy. The ArrayFIX has no apparent risk of electrical short circuit, because there is only one particle between bumps. On the other hand, the conventional ACF has four particles between the bumps. Although they are not in contact in the image, they are quite close together. There is a possibility of electrical short circuits, if the conductive particles come into contact with each other. The ArrayFIX has a lower risk of electrical short circuits than conventional ACFs, by reviewing only the cross-sectional view.

In the case of the ArrayFIX, cross-sectional observation is relatively easy, because the relative position of particles can be approximated. On the other hand, with conventional ACF, it is difficult to view the connections or short-circuits in a single cross-sectional view because the position of the conductive particles is not predetermined. In the cross-sectional view of the conventional ACF, the bump on the left does not appear to be capturing any conductive particles. However, an assumption could be made that the conductive particles are either in the front or back areas that are not on the image.

Streamlined quality checks

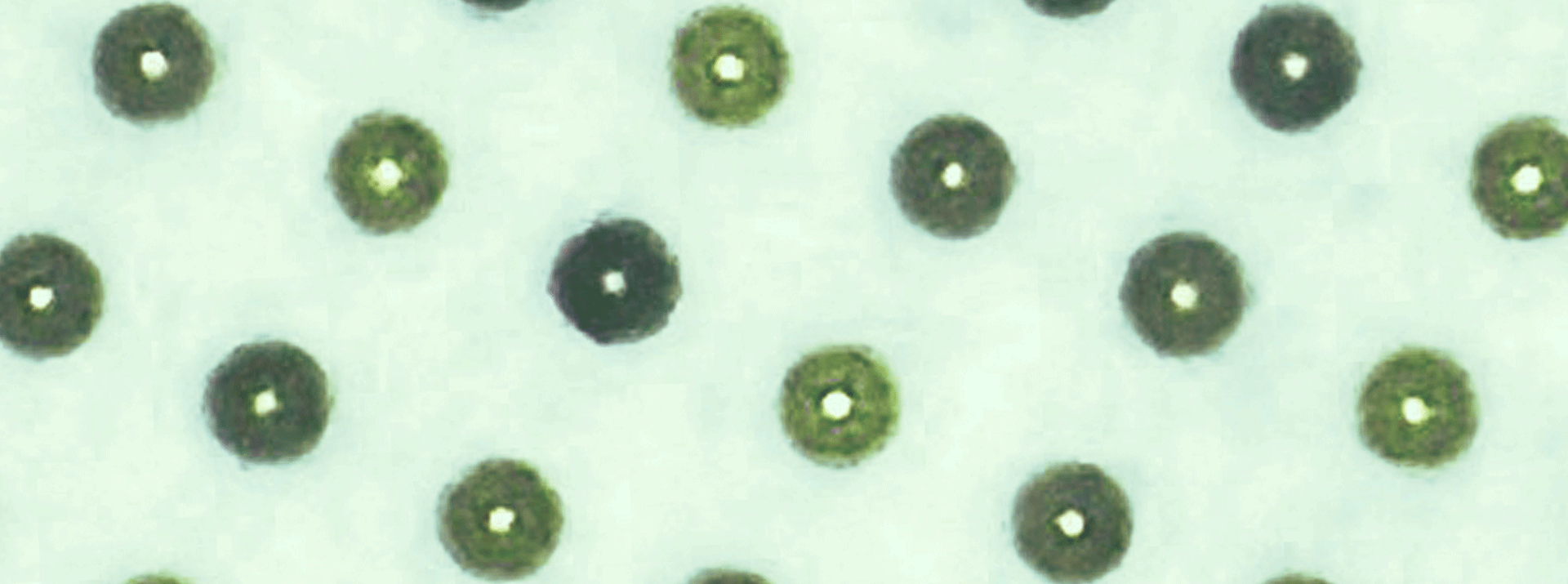

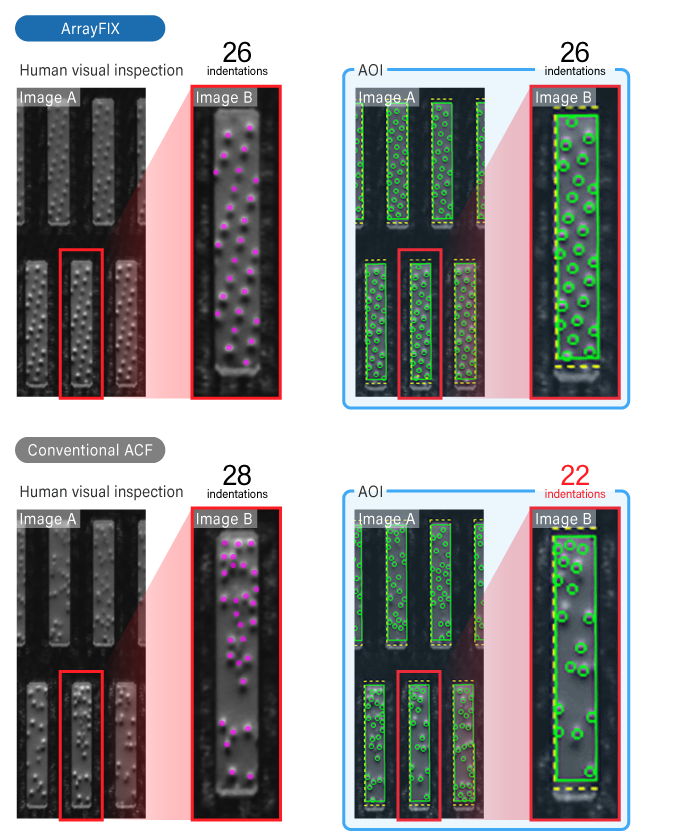

Microscopic images such as differential interference contrast microscopy are used for quality checks, since destructive testing (cross-sectional observations) cannot be conducted at assembly sites. The following images were used to inspect the bonding quality. The same section was reviewed by a human inspector (results on left) and an automatic optical inspection (AOI) device (results on right).

The narrow rectangles on the above images show the connected pads and the white dots called “bond mark” that indicate the location of the captured ACF conductive particles. The image of the captured conductive particles is shaded (Image A). Image B is an enlarged image of the red frame in Image A. The pink dots indicate bond marks determined as normal by the human eye, and the green circles indicate bond marks determined as normal by the AOI system.

For ArrayFIX, both the human visual inspection and AOI show 26 bond marks (normal connections). On the other hand, in the conventional ACF, the AOI only identified 22 bond marks, even though the human visual inspection identified 28 bond marks. This is because multiple bond marks in close proximity to each other are judged as a single bond marks by the AOI.

The AOI inspection would have failed, if the number of bond marks in the aforementioned example for conventional ACF was 24 or more. In this case, an additional inspection would be conducted by a human inspector, who would then determine the final number of bond marks to be 28. Thus, performing an AOI inspection with a conventional ACF results in fewer inspections per hour and requires additional human inspection.

On the other hand, the conductive particles in ArrayFix are uniformly spaced, so bond marks are not counted twice. This reduces misjudgments in the inspection process, improves product inspection accuracy, and reduces inspection time, because bond marks are clearly visible on the AOI image.

New design possibilities by arranging particles

The position of the dispersed conductive particles cannot be set in advance in conventional ACFs. Therefore, a probability distribution function is used to determine the number of particles captured between pads. On the other hand, ArrayFIX’s particles are arranged evenly at targeted positions. The concept of tolerance, used in mechanical engineering, is used to predict the number of captured particles.

Until now, the process of checking the validity of a new design was to prepare, assemble, and evaluate components. If an evaluation showed that the design is not viable, the root cause has to be investigated and the above stated process will repeat until the design passed the evaluation. However, it helps reduce the likelihood of repeating the aforementioned process ,since ArrayFix captures a precise number of particles. Furthermore, it ensures reliable conduction and reduces the risk of electrical short circuits.

As the leading manufacturer of ACFs, Dexerials has developed various technologies to design advanced ACFs product line-up. Dexerials and our ArrayFIX will continue to evolve to satisfy any customer needs.

ArrayFIX and its logo are trademarks or registered trademarks of Dexerials Corporation in Japan and other countries.

- SHARE

Back to top

Back to top  Contact us

Contact us