- Bonding Products

Latest optical bonding technology for 3D & 2.5D in-vehicle displays

Contents

In-vehicle displays with improved designs

Automotive OEMs and Tier 1 suppliers have started improving the functionality of in-vehicle displays to enhance driving experience. Although most conventional displays are flat and rectangular, recently there has been an increase in the development of curved or ‘free-form’ displays that match the shape of the interior. The development of these new displays requires new optical bonding technologies, which is the process of laminating a display and the cover material.

‘Optical lamination’ refers to the lamination of a display module, such as an LCD panel, and the cover lens (top substrate), with an optically clear adhesive.

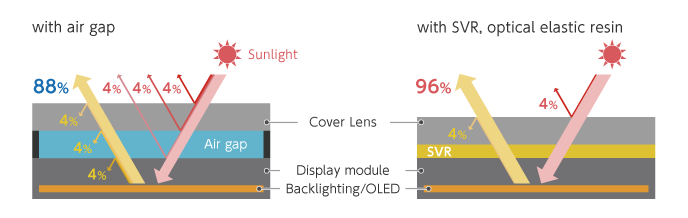

Glass or acrylic polymers are usually used as top substrates, but air gaps between the display and cover lens can cause blurred images and reduce brightness due to the difference in the refractive indices. Therefore, OCAs (Optically Clear Adhesives) and LOCAs (Liquid Optically Clear Adhesives) are used to fill any air gaps between the display and top substrate. The optically clear adhesive bonds substrates together while minimizing both the reflection of outside light and the diffusion of image light inside the panel. Such adhesive materials with high transparency are also commonly used in smartphones.

Bonding curved surfaces with LOCA

OCAs and LOCAs not only improve screen visibility due to matched refractive indices, but also contribute to passenger safety by preventing glass and acrylic fragments from shattering in the event of a car accident. In addition, optical lamination resin improves the dust and moisture resistance of displays, making it an indispensable component of many in-vehicle display systems.

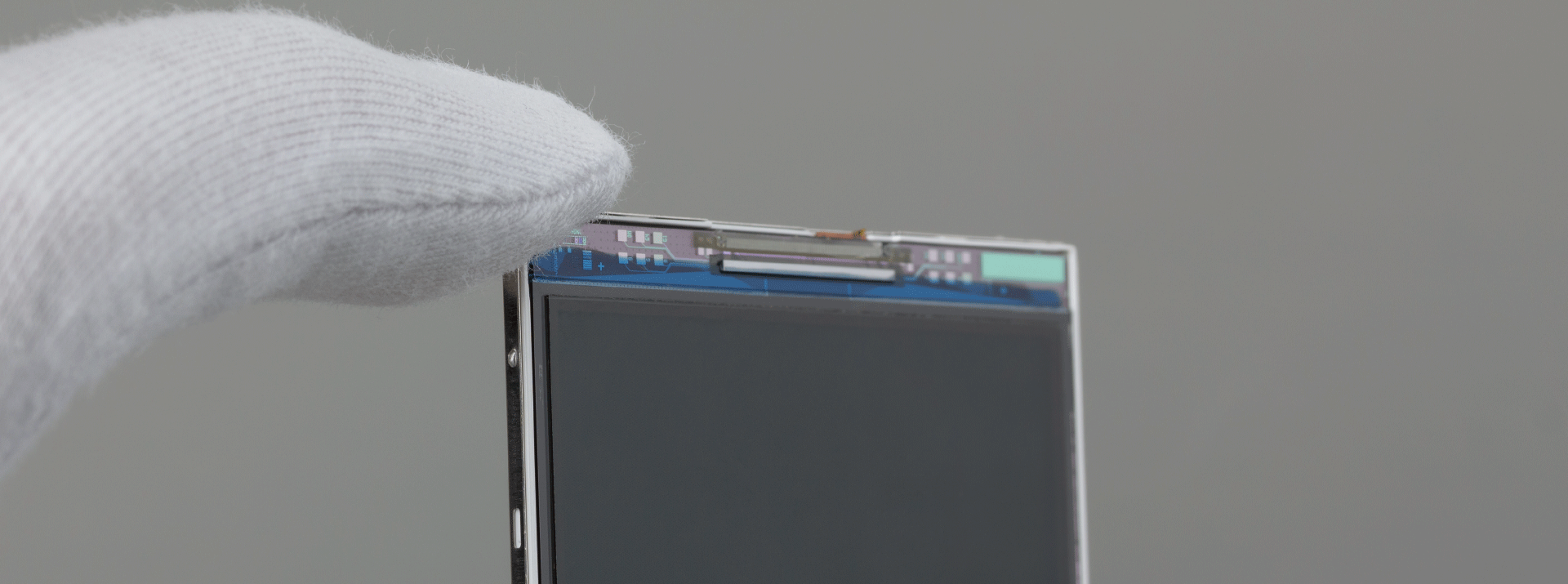

However, the increasingly popular free-form and curved in-vehicle displays are less suitable for OCA’s application. Since OCA is a flat film, it is mainly used for bonding flat substrates and is not suitable for uneven surfaces with varying thickness inks or curved surfaces.

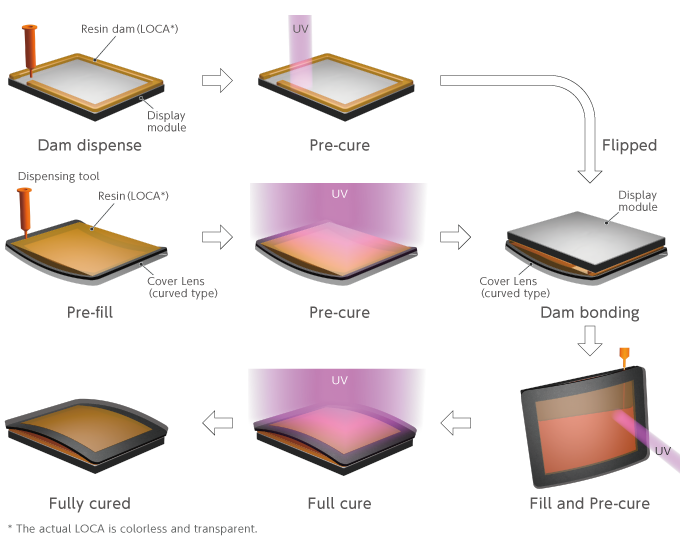

In contrast, LOCAs, as liquid polymers, can fill in any gaps between the bonding areas. As shown in the following figure, the LOCA is filled between the curved cover lens and the display and cured with UV light in stages to create a perfect bond. Thus, LOCAs are suitable for bonding curved 2.5D and 3D displays.

Optical Elastic Resin (SVR) Series

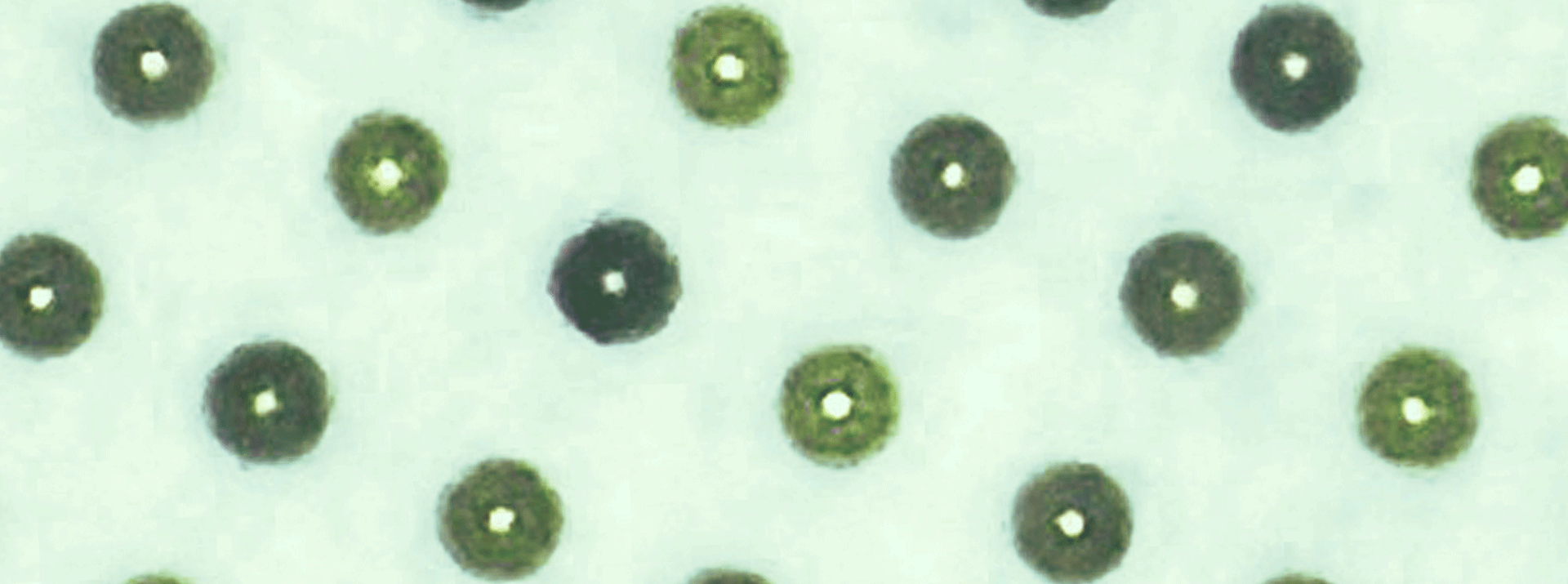

Dexerials was the first in the industry to develop in 2007 an acrylic LOCA which we called “SVR,” an optical elastic resin used in many smartphone displays. In 2013, “Hybrid SVR” was commercialized as a polymer applied on the backside of the cover lens and cured with UV light. Hybrid SVR became more popular in optical bonding applications as it provided improved optical performance and advantages of both SVR and OCA respectively.

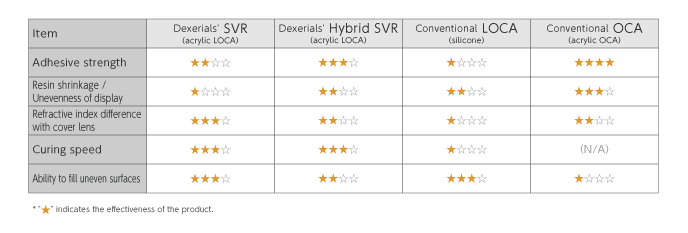

The following table compares the properties of SVR, Hybrid SVR, and competitors’ silicone and acrylic LOCAs. The “★” symbols indicate the effectiveness of the products (the higher the number of “★,” the more effective adhesive).

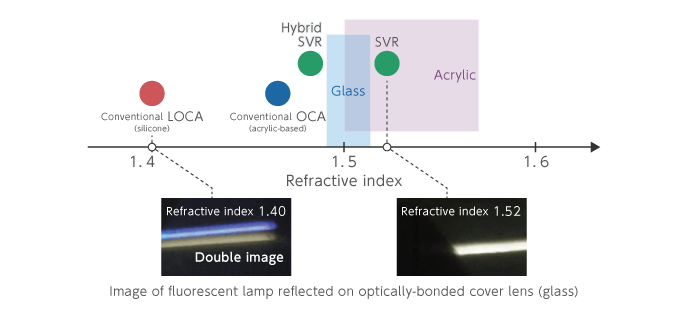

Until now, silicone LOCAs have been the primary material used in optical bonding for automotive displays. However, because of a large difference in their refractive index and refractive index of glass or polycarbonate substrate , silicone LOCAs do not completely solve the issues of blurred and double images. Furthermore, silicone LOCAs have weaker adhesion than OCAs. In contrast, acrylic SVRs’ and hybrid SVRs’ refractive index is almost the same as refractive indices of glass and polycarbonate, which greatly improves resin’ optical properties. Additionally, Dexerials’ acrylic SVRs and Hybrid SVRs have higher adhesive strength, second only to that of OCAs.

Acrylic SVR-series with high temperature resistance

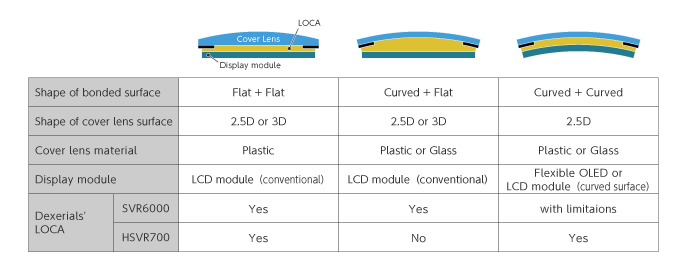

The following figure shows a cross-sectional view of 2.5D and 3D displays. It shows three combinations of varying top substrate and display type with either SVR or hybrid SVR as a bonding resin. It is expected that the displays type with both curved top substrate and module (right-most combination) will prevail as free-form displays continue to grow in the market. Hybrid SVRs with two-step UV curing can be used for curved display applications.

Until now, silicone LOCAs have been conventionally used for automotive display optical lamination due to higher temperature resistance of silicone adhesives. However, the SVRs and hybrid SVRs developed by Dexerials have shown no deterioration in quality after durability tests at 95°C for 1,000 hours, and are fully suitable for use as in-vehicle display bonding materials. Dexerials will continue promotion of SVRs and hybrid SVRs, which offer improved optical performance, greater design flexibility, and enhanced adhesion.

- SHARE

Back to top

Back to top  Contact us

Contact us