- Bonding Products

Introduction to ArrayFIX®, a particle-arrayed ACF

Contents

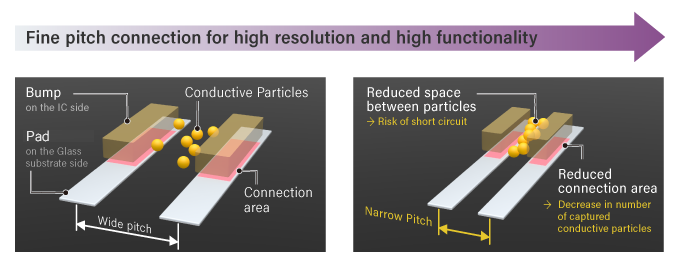

ACFs are essential for fine pitch connections of high-definition flat-panel displays

Flat-panel displays used in smartphones, tablet PCs, and large-screen TVs are becoming progressively high definition every year. Component density is also increasing as digital devices become more multifunctional. These trends have led to a growing need for fine-pitch bonding to electrically and mechanically bond glass substrates and IC chips that make up the displays.

In 1977, Dexerials commercialized Anisotropic Conductive Film (ACF), an adhesive for IC chips bonding. Today, it is used in many applications to attach IC chips on glass substrates of smartphones and tablet PCs. ACF consists of conductive particles dispersed in a thermoset resin. With ACF, many electrodes can be connected at once by applying heat and pressure. Insulating material covers the conductive particles of ACF. When opposing pads capture the particles, it breaks the coating to create electrical connections between the pads. The uncaptured particles maintain their insulating properties and prevent short circuits between adjacent pads.

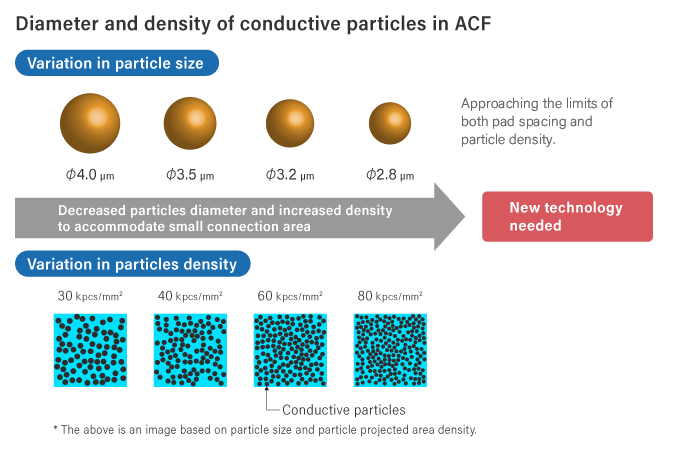

ACFs have rapidly become popular because they are more suitable for fine pitch connections than soldering or mechanical connections. Dexerials has reduced the size and increased the number of conductive particles in ACF to meet the demand for finer pitch connections and smaller connection areas.

Conventional ACFs contain dispersed particles in the resin, and as the number of particles per area increases, the probability to capture particles increases as well. However, with the requirement of high-definition displays, combined with a reduction in connection area due to the increase in component density, this approach began to reach its limits in the 2010s. Too many particles will cause clogging between pads, increasing the risk of short circuits.

Breakthroughs in “aligning” and “fixing” conductive particles

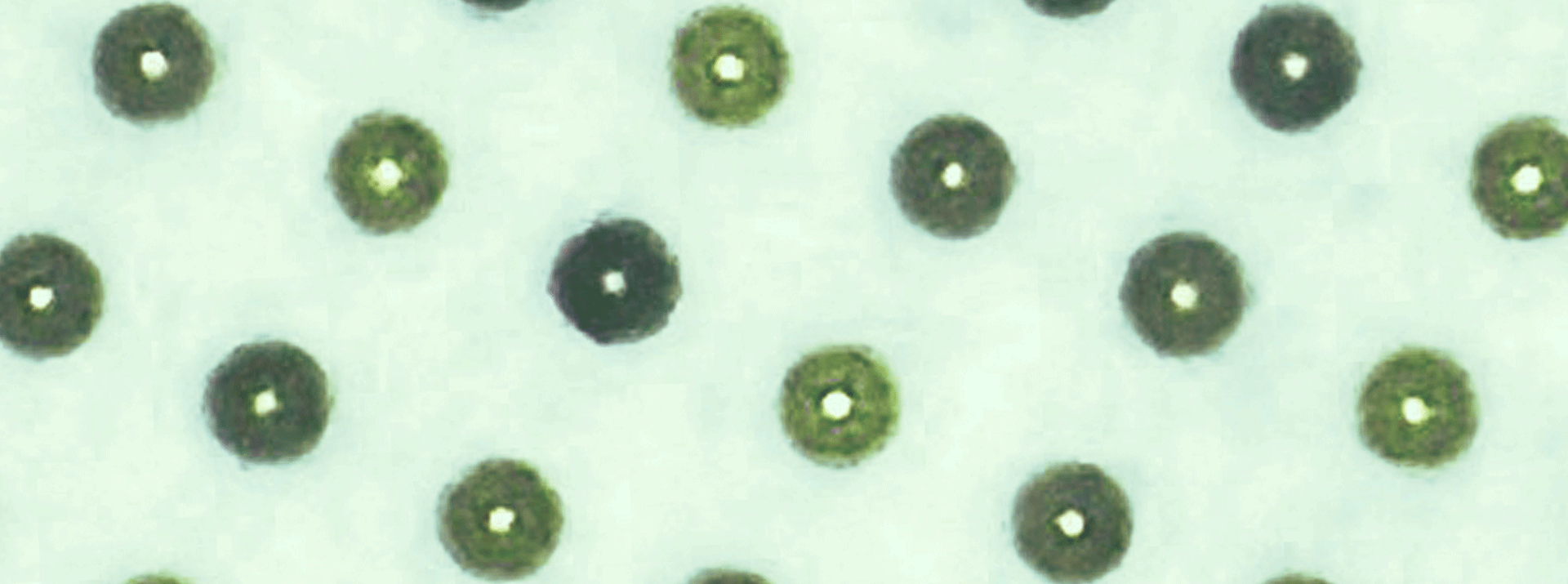

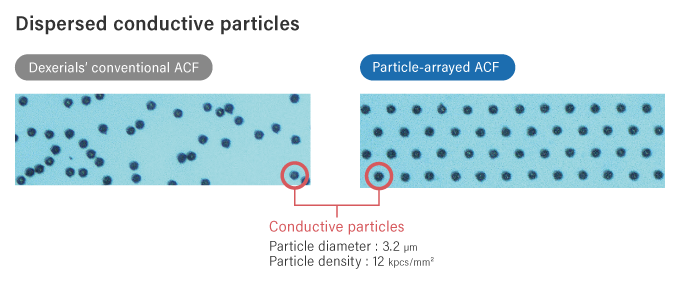

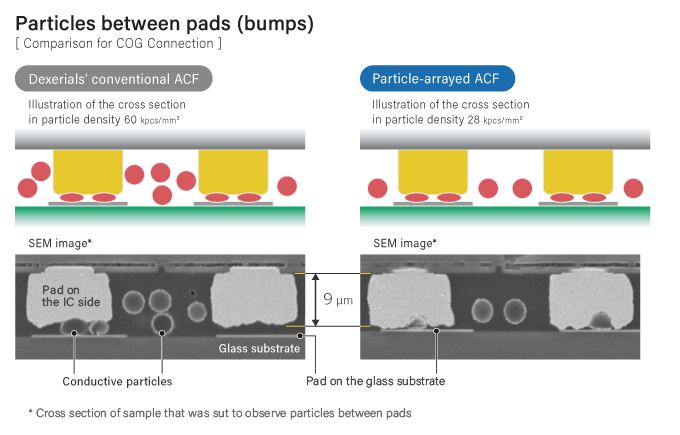

The question was, “How can we get finer pitch connections without changing the size or increasing the number of particles?” Dexerials’ solution was “not to increase the number of particles, but to reduce the number of conductive particles and arrange them evenly at targeted positions.” The following images show the comparison of dispersed particles between Dexerials’ conventional ACF and the “particle-arrayed ACF” developed in 2014. Particles of the conventional ACF are randomly dispersed, whereas particles of the “particle-arrayed ACF” are evenly spaced and aligned.

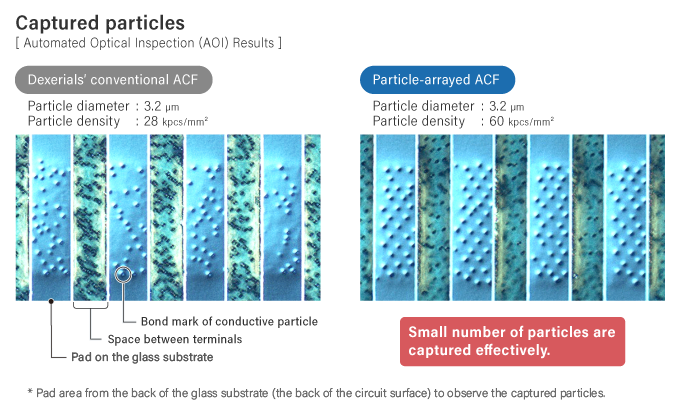

By arranging conductive particles at regular intervals in this way, the number of captured particles in the pads can be stabilized even with the same particle number per area, thus ensuring reliable conduction. In conventional ACF, when heat and pressure are applied, the resin softens and flows into a lower pressure space (a space without pads). The resin flow moves the conductive particles and reduces the number of particles in the area with higher pressure, between the opposing pads, and increases the number of particles in the area with lower pressure, between adjacent pads.

However, the newly developed “particle-arrayed ACF” uses a resin that suppresses the move of aligned particles. Thereby ensuring reliable conduction over a small connection area even with a small number of particles and reducing the risk of short circuits as the particles rarely move during bonding. Dexerials named the product “ArrayFIXⓇ,” which uses this technology of aligning (Array) and fixing (Fix) particles.

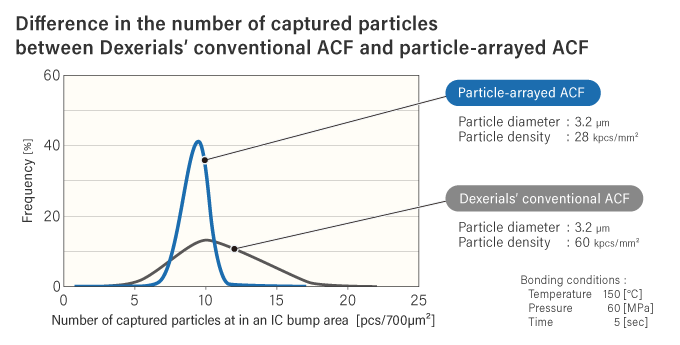

ArrayFIX® technology enables finer pitch connections

Below is a micrograph of an IC chip connected to a substrate using conventional ACF and particle-arrayed ACF. The particle-arrayed ACF on the right has 53% fewer particles than the conventional ACF, reducing the number from 60,000 to 28,000. In addition, the minimum connection area is also reduced by 77%, from 1300 μm2 to 300 μm2, and the minimum pad spacing can be reduced by 17%, from 12 μm to 10 μm.

ArrayFIXⓇ, particle-arrayed ACF, can provide fine-pitch connections with a minimum bump spacing of 10 μm as well as, highly reliable connections for IC bonding on high-resolution display panels. With advancements of 4K displays and 5G communications, it is expected that mobile devices will be designed with higher resolution and more beautiful displays. ArrayFIXⓇ can provide reliable connections for cutting-edge displays and support the development of new digital devices.

- SHARE

Back to top

Back to top  Contact us

Contact us