- Bonding Products

The Cutting Edge of Automotive Lighting: OLED Taillights and Dexerials’ Anisotropic Conductive Film (ACF)

Contents

- 1 Lighting the path of automotive progress: the evolution of OLED taillights

- 2 The history of light sources for automotive taillights

- 3 Legal requirements for automotive taillights (comparison of Japan, US, and Europe)

- 4 The characteristics of OLED lighting and comparison with other light sources

- 5 Adoption example from a European automaker and future outlook

- 6 Dexerials’ contribution to automotive OLED taillights

- 7 OLED and the future of automotive lighting

Lighting the path of automotive progress: the evolution of OLED taillights

Automotive taillights play important roles in both the safety and design of a vehicle. Luxury car brands, particularly those from Europe, have begun adopting OLED lighting as a light source in recent years, gathering attention from the industry and beyond for their innovation. This article will explore the changes this technology is bringing to the automotive industry, technological advances in taillights, the characteristics of OLED lighting, and the outlook for the future.

While OLED technology was originally developed for consumer electronics such as smartphones and televisions, advances in reliability and cost reduction have enabled applications in the automotive field. OLED’s thinness and flexibility are two reasons that high-end automotive brands in particular are adopting the technology to enable greater freedom in vehicle design.

In addition, the industry overall is focused on the need to improve energy efficiency as environmental regulations are strengthened. OLED consumes less power compared to conventional light sources and is playing a role in improved energy savings for electric vehicles (EVs) in particular. And with advances in autonomous driving technology, lighting control is drawing attention as a communication method between the vehicle and its surroundings. Here, too, OLED’s flexible control of light emission patterns expands those possibilities. For example, the high visibility provided by uniform surface emission contributes significantly to safety improvement and accident prevention.

The needs of technological advancement and environmental concerns constantly influence each other. As they do, the importance of OLED lighting in the automotive taillight market continues to grow. Further developments are expected not only in the European market but also in Japan and across other Asian markets.

The history of light sources for automotive taillights

How has light source technology for automotive taillights evolved? As the automobile developed, light sources have evolved as well. Here, we will examine that evolution from the early 1900s to the newest OLED technology.

Early 1900s:

Incandescent bulbs were used for taillights during this period. While they were known for high reliability at the time, energy efficiency was low and operational lifespan was short.

1960s:

Halogen lamps replaced incandescent bulbs. Halogen lamps were brighter, had longer lifespans, and enabled compact designs to offer greater flexibility in automotive design.

1990s:

As LED technology advanced, it began to see use in automotive taillights. LEDs offered high brightness, low power consumption, long-life, and expanded design diversity through miniaturization. In particular, their fast response time greatly enhanced the safety performance of brake lights.

2020s:

OLED lighting emerged as the latest technology. Its ability to produce light evenly distributed across a surface, thinness, and flexibility can enable even complex 3D designs. This support for high-end design is leading to adoption by luxury car brands.

We can see how the technological evolution laid the groundwork for the current spread of OLED technology. Next, we will examine legal requirements in detail.

Legal requirements for automotive taillights (comparison of Japan, US, and Europe)

The rear of an automobile is equipped with lights such as taillights, brake lights, and reverse lights. Each is subject to different legal requirements established by each country and region. The table below shows the primary differences between taillights, brake lights, and reverse lights.

| Light type | Color | Function | Light activation | Characteristics |

|---|---|---|---|---|

| Taillight | Red | Makes the vehicle visible from behind | Always on during nighttime operation or low visibility conditions | Relatively low brightness, energy-efficient design for constant lighting |

| Brake light | Red | Notifies those behind of slowing/stopping | When the brake pedal is pressed | Higher brightness than taillights, requires fast response |

| Reverse light | White | Notifies those in the vicinity that the vehicle is backing up | When the vehicle is put in reverse | Illuminates a wide range to increase visibility to the rear |

While legal requirements have many points in common, Europe in particular has detailed regulations related to luminous intensity and light distribution to address new technologies such as adaptive rear lighting systems (ARS). We can see that Japan and the US also have strict brightness standards to ensure visibility at night and in inclement weather.

| Item | Japan | US | Europe |

|---|---|---|---|

| Standards | Safety Standards for Road Transportation Vehicles | Federal Motor Vehicle Safety Standards (FMVSS) | United Nations Economic Commission for Europe (UNECE) regulations |

| Color | Red | Red | Red |

| Visibility | Visible from 50 m behind at night | Detailed regulations for minimum luminosity | Detailed regulations for luminosity, chromaticity, and light distribution |

| Position | Left-right symmetry | Left-right symmetry | Left-right symmetry |

| Notes | — | Clear differentiation from brake lights required | Regulations for adaptive rear lighting systems (ARS) |

Because automotive taillights are directly related to safety, countries and regions have established strict regulations as shown above. OLED technology leverages strengths such as even distribution of light emission across a surface and rapid responsivity to significantly improve tail and brake light performance while complying with these regulations.

Next, we will take a detailed look at OLED’s advantages over other light sources.

The characteristics of OLED lighting and comparison with other light sources

OLED devices are surface-emitting light sources made of organic semiconductor materials that emit light when electric current is applied. Because there is no need for a back light, their extreme thinness, flexibility, and ability of the light-emitting surface to bend seamlessly allows OLED lighting to play an innovative role in automotive taillights.

OLED has a number of advantages and challenges. One of the benefits is the ability to create a high-end appearance through uniform surface emission. Their thin and flexible nature allows for design freedom that was difficult to achieve with traditional light sources. Additionally, OLEDs can operate at low voltage, contributing to high energy efficiency.

One disadvantage, on the other hand, is the high cost. As a result, adoption is currently difficult for mass-market vehicles. In addition, there are challenges with durability and lifespan relative to other light sources, further work is required to extend lifespans. There are also concerns about performance degradation in high-temperature environments, and there is a need to maintain performance under harsh use conditions.

The table below summarizes the characteristics of OLED, LED, and halogen lamps.

| Characteristic | OLED | LED | Halogen |

|---|---|---|---|

| Brightness | ★★☆ Lower brightness than LED | ★★★ High brightness | ★★★ High brightness |

| Uniformity | ★★★ High uniformity due to surface light emission | ★★☆ Requires effort to achieve uniformity | ★☆☆ Low uniformity |

| Energy efficiency | ★★☆ Better than halogen | ★★★ Highest efficiency | ★☆☆ Lowest efficiency |

| Design freedom | ★★★ Extremely thin, flexible, can be shaped freely | ★★☆ Miniaturization is possible but requires heat dissipation design | ★☆☆ Requires a relatively large space |

| Durability and lifespan | ★★☆ Approx. 40,000–50,000 hours | ★★★ Long-life (50,000+ hours) | ★☆☆ Relatively short lifespan (2,000–5,000 hours) |

Adoption example from a European automaker and future outlook

One high-end European automaker has adopted OLED taillights on a large scale beginning with the 2020 model year. The innovative design and functionality have drawn attention from the industry and beyond. In particular, the three-dimensional and uniform light effect made possible by segmented OLED panels has become a new standard that solidified OLED’s position as the next-generation lighting technology for taillights.

This innovation offers not only visual sophistication but also an enhanced user experience through dynamic lighting features that adapt light patterns in response to vehicle status. In terms of safety functionality, it can change the light pattern as a visual prompt when a vehicle comes too close from behind, contributing to accident prevention.

In the future, further advancements in OLED technology are expected. Cost reduction and improved durability would enable adoption in more vehicles and mid-range models. In particular, the technology may be picked up not only by design-focused European automakers but by Asian automakers aggressively adopting EV technology. Additionally, the development of smart lighting systems, integration with Vehicle-to-Everything (V2X) communication, and AI control will enable more advanced adaptive lighting. The fusion with augmented reality (AR) technology will transform taillights from mere lighting devices into information display devices.We can see that OLED taillight technology has the potential to make a significant impact on future automotive lighting through both design and safety.

Dexerials’ contribution to automotive OLED taillights

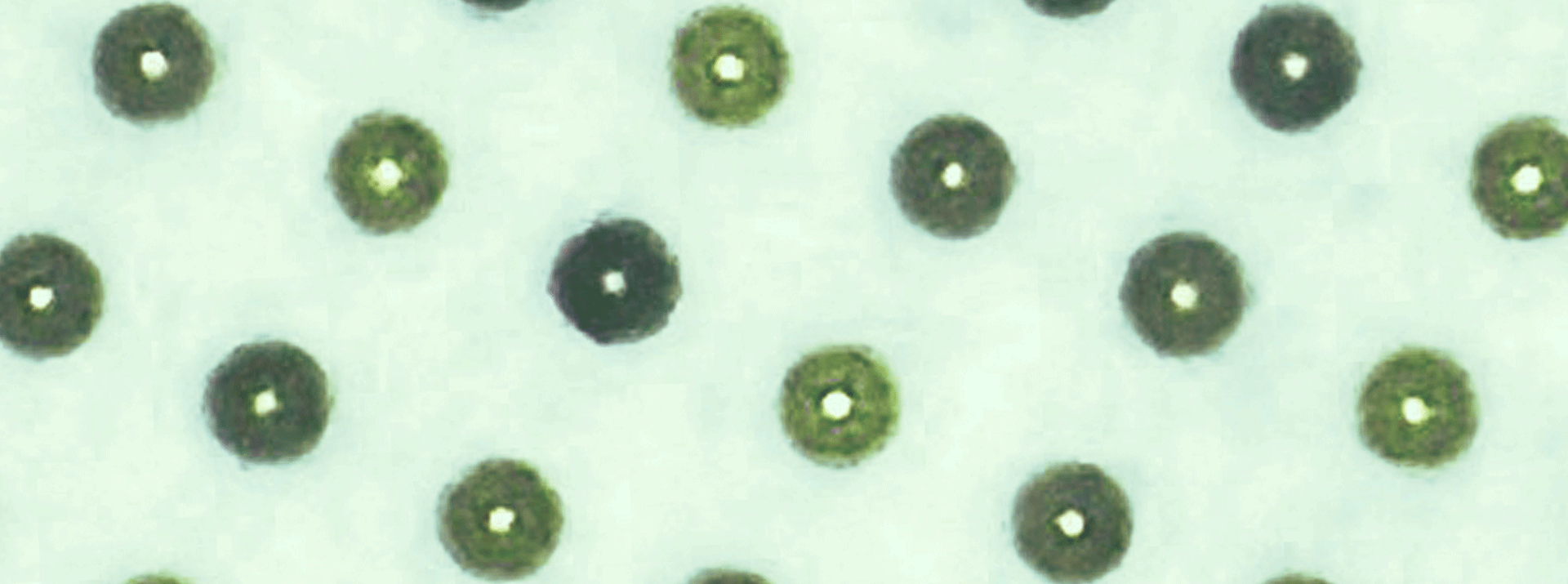

Dexerials provides solutions that leverage unique material technologies to contribute to the growth of the automotive OLED taillight market. Our anisotropic conductive film (ACF) is widely used not only in automotive center information displays (CIDs) and advanced driver assistance system (ADAS) camera systems but also in connecting OLED panels and flexible printed circuits (FPCs). Since OLED performance degrades when exposed to high heat, the low-temperature bonding capability of Dexerials’ ACF helps minimize panel damage during the manufacturing process.

In addition, stricter environmental regulations are leading to demand for connection processes that reduce the environmental load of automotive components. Here, too, Dexerials technology is contributing to efforts toward improving thinness and reducing connection area. This enables us to propose optimal connection methods that meet product specifications, production quantity, cost, and environmental requirements, thereby supporting further technological innovation in the automotive industry.

OLED and the future of automotive lighting

OLED lighting technology is opening up new possibilities for improvement in the design, energy efficiency, and safety features of automotive taillights. It offers many advantages such as design freedom and energy efficiency, but challenges remain with regard to cost and durability.

We will take on these challenges and leverage our technical expertise to contribute to automotive lighting technology. If you are interested in the next generation of automotive lighting design, please contact us for a consultation. Let’s work together to realize the lighting solution of the future!

- SHARE

Back to top

Back to top  Contact us

Contact us