- Bonding Products

Features and Benefits of Using Anisotropic Conductive Film (ACF) for Smart Cards

Contents

Increasingly multifunctional IC cards

There are probably many cards in your wallet, including but not limited to debit, credit, and public transit cards. In recent years, smart cards, cards with IC chips, have been playing an essential role in our everyday lives. Compared to conventional magnetic stripe cards, those with IC chips have a much larger storage capacity and offer a wider range of functions.

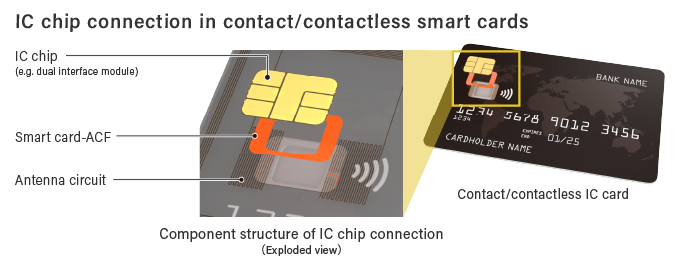

Until recently, the Anisotropic Conductive Film (ACF) developed by Dexerials has been mainly used as an interconnection material for displays in smartphones, tablet PCs and large-screen TVs. Nowadays, however, ACFs are also being used in the above-mentioned multifunctional smart cards as a bonding material. Below is a diagram showing where Dexerials’ ACFs are used inside modern smart cards.

There are two types of smart cards: contact, in which the information on the IC chip is read directly by the device, and contactless, in which the information is exchanged by sending radio waves from the internal antenna. One of the uses of ACFs is to connect the IC chip with the antenna circuit in contactless smart cards. In addition, some recent IC cards are equipped with liquid crystal displays or electronic paper displays that can show information such as balance, points, and coupons using internal batteries. ACFs are used for the interconnection of these displays as well. In some countries, companies have implemented IC cards with fingerprint biometric authentication capabilities, and there is potential for ACFs to be utilized in fingerprint authentication sensors as well.

※Link: Anisotropic Conductive Film (ACF): a key part of biometric cards

Features of ACFs for smart cards

As mentioned above, ACFs are a bonding material that can be used to connect components in smart cards. Using credit cards (contact and contactless IC cards) as an example, we will explore the features of IC card-ACFs used for bonding IC chips.

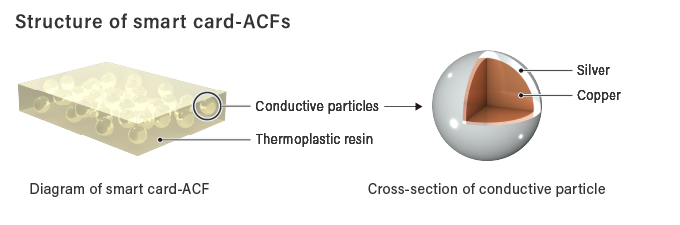

In general, ACFs are characterized by conductive particles embedded in the resin, which can conduct electricity while bonding IC chips to circuits and insulate adjacent pads to prevent electrical short circuits. Smart card-ACFs are also beneficial for adhesion, conductivity, and insulation. Unlike display ACFs, electrical short circuits due to jamming of conductive particles are rare thanks to the wide spaces between pads. For this reason, there is no insulation coating on the conductive particles of Smart card-ACFs.

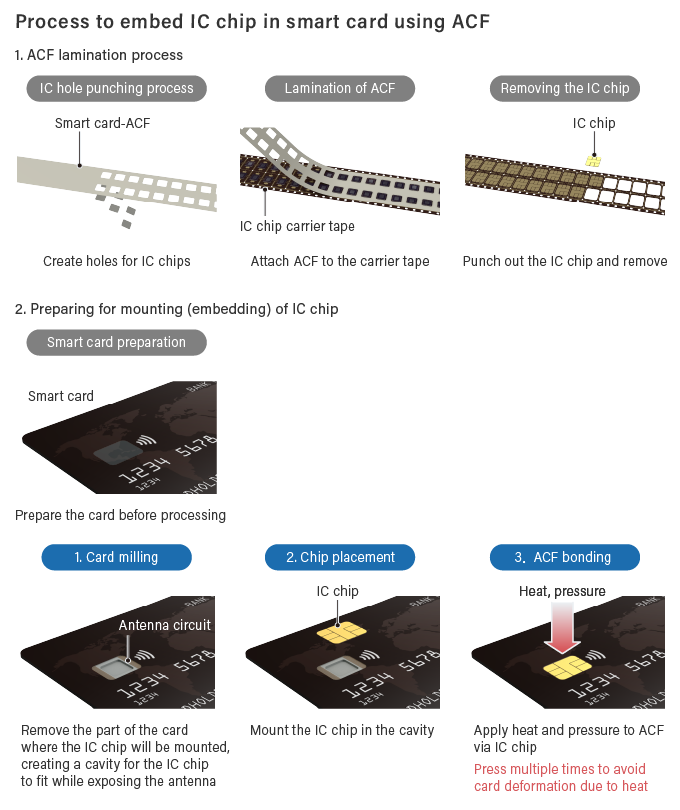

Smart card-ACFs must be non-sticky so that the IC chip and ACF on the reel do not stick to each other before being transferred to the card. In addition, in the thermo-compression process, the bonding time is reduced to 0.5-1.5 seconds at a time to prevent the card from being deformed by the heat, and multiple bonding (2-4 times) is performed to provide the necessary thermal energy for bonding. Smart card-ACFs are also required to have flexible punching capabilities to match the shape of the ACF to various IC chips and fingerprint sensors. In Addition, smart card-ACFs must be able to be stored at room temperature after bonding to the IC chip and before thermo-compression bonding to the card.

ACFs used for smart cards are also wider than ACFs used for displays due to a larger connection surface. IC card-ACFs are shipped in wide rolls of 29mm (see photo below) while display ACFs are approximately 1mm width. The illustration above shows how an IC chip is mounted on a smart card using ACF.

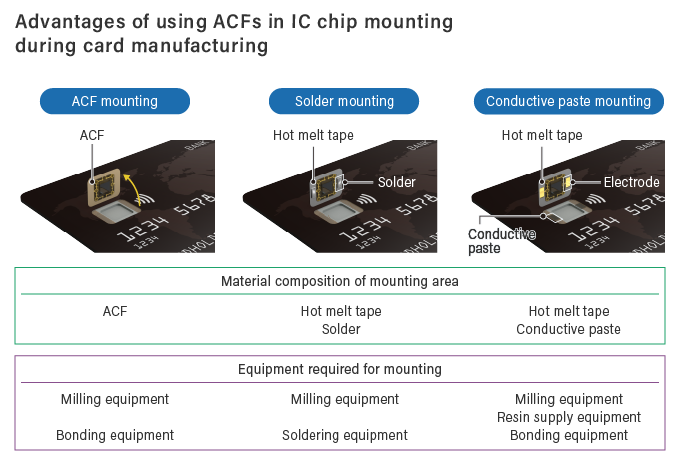

Advantages of implementing ACFs in IC card manufacturing

Other methods of embedding IC chips in Smart cards include soldering and hot melt tape, or conductive paste and hot melt tape. As shown below, both the solder mounting and conductive paste mounting method require two types of materials as well as a special equipment for each process. However, Dexerials’ Smart card-ACF can significantly reduce material and equipment costs compared to the other methods.

Smart card-ACFs use the same spot face process used to create holes in the cards as conventional methods. It can be implemented immediately as long as there is equipment to embed the IC chip. One of its biggest advantages is that both contact and contactless cards can be manufactured with this one piece of equipment.

A growing number of customers is considering usage of Dexerials’ smart card-ACFs to reduce costs. ACFs are effective in incorporating new functions as various attempts are being made to add new features such as biometric authentication.

There has been an increase in the number of “dual interface cards,” Smart cards that have both contact and contactless functions on a single card. It can be a heavy burden for manufacturers to install new production facilities to produce cards with new specifications. Dexerials’ ACFs can respond to both current and new specifications, and may be the right solution for your business.

- SHARE

Back to top

Back to top  Contact us

Contact us