- Bonding Products

RFID Basics (Future Prospects and Anisotropic Conductive Paste)

Contents

What is RFID?

What do you picture when you hear the word “RFID tag”? This term may not sound familiar to many, but it actually refers to something closely related to our daily lives.

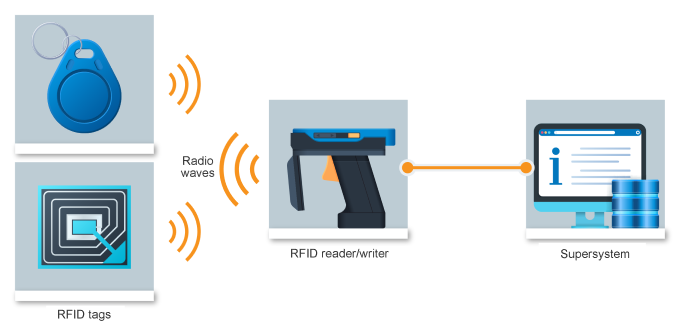

RFID, an acronym for Radio Frequency Identification, is a system for contactless information reading and writing. This system involves radio (electromagnetic wave) transmissions between RFID tags and RFID readers/writers to enable the automatic identification of objects, people, and their states. This technology is utilized in various industries.

Those who have participated in a large marathon competition may have used RFID tags. These tags, attached to the runner’s shoes or bibs, are read by special scanners installed at the start and finish lines. This setup automatically records runners’ finishing times as they cross the line, with most participants unaware that tags are even attached onto their bibs.

Leading Japanese apparel chains use unattended checkouts for a smoother payment experience. These units incorporate RFID readers/writers to automatically recognize RFID-tagged items, thereby eliminating the need to scan each item individually. This method is more efficient and less prone to scanning errors than traditional barcode scanning.

Another superb characteristic of RFID is its ability to scan multiple tags simultaneously, regardless of visibility or distance. This characteristic facilitates the management of items stored on high shelves or inside boxes, helping logistics and retail companies save time and achieve accurate inventory control.

RFID mechanism

RFID is used in many everyday situations, such as transportation cards, electronic money, card keys, event entrance and exit control, and food expiration management in the food industry. Now, let’s explore how RFID reads and writes information.

- Radio wave transmission: An RFID reader/writer emits radio waves at specific frequencies from its antenna.

- Radio wave reception and IC chip operation: The antenna of an RFID tag captures these radio waves and converts the energy into electric signals to power its integrated circuit (IC) chip.

- Data signalization and transmission: The IC chip reads its stored information (code information) and sends it back via the tag’s antenna in the form of signals.

- Signal reception: The RFID reader/writer’s antenna receives these signals.

- Information forwarding and processing: The received signals are then transferred to a connected mobile device or PC via the reader’s control unit.

This entire process is completed very quickly and can be repeated numerous times per second. This rapid processing is crucial for saving time and effort while ensuring the accuracy of the data.

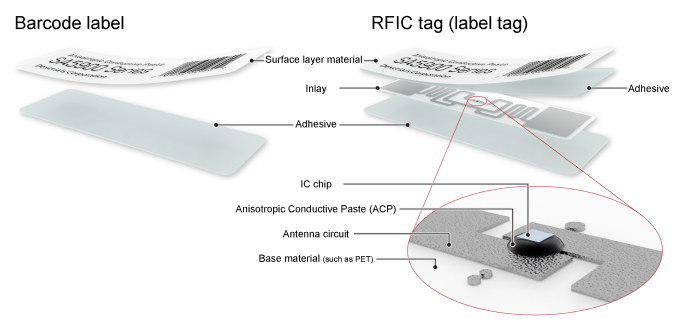

Basic structure of an RFID tag

This section outlines the structure of a label tag, a general-purpose type of RFID tag, as an example. The label-type RFID tag consists of a surface layer, an adhesive, and an inlay, which includes an IC chip and an antenna for data transmission. The key distinction between RFID tags and barcode labels commonly found in supermarkets lies in the presence of this inlay.

Given that the use cases for RFID tags require error-free data transmission, their production involves various technologies to ensure precision and accuracy.

Dexerials’ ACP*1 is an adhesive that efficiently connects the IC chip to the antenna within an RFID tag, enhancing the efficiency and speed of the inlay production process.

*1 Anisotropic conductive paste

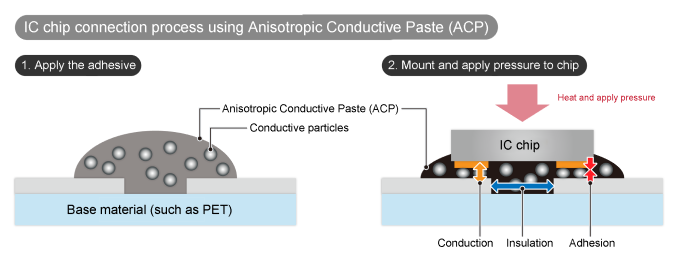

This connection must meet the following criteria: (1) electrical conduction, which involves connecting the electrodes to form an electric circuit, (2) insulation, which prevents short circuits, and (3) adhesion, which securely fixes the IC chip in place. Some manufacturing processes involve separate steps to meet each criteria (1), (2), and (3), but our special ACP adhesive meets all these criteria simultaneously, enhancing efficiency. The ACP is liquid and compatible with jet air dispensers and other equipment that can rapidly apply a small volume of liquid without contact. This precise and minimal application not only boosts productivity but also reduces costs.

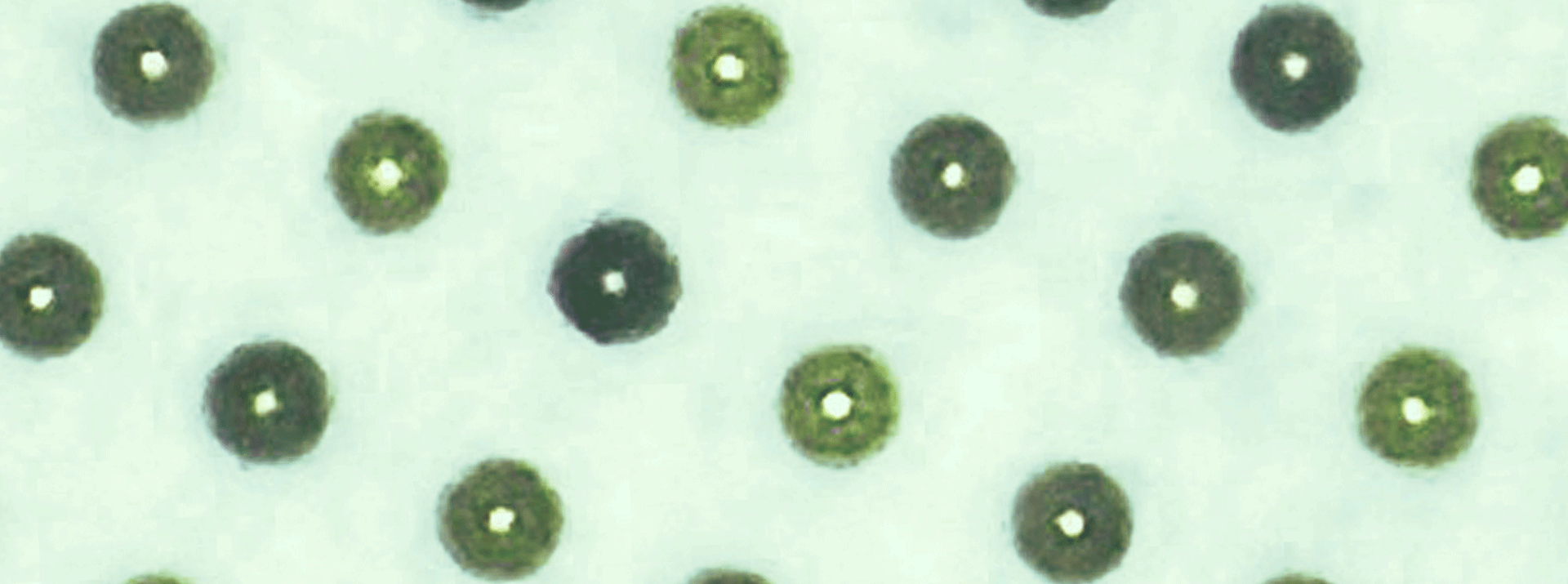

The criteria for (1) electrical conduction and (2) insulation are met by micron-sized conductive particles dispersed within the adhesive. These particles facilitate electricity flow between the IC chip and the antenna while insulating them from adjacent circuits. The criterion for (3) adhesion is achieved through a special thermosetting resin that ensures prolonged durability and reliability.

Development of a fast-curing ACP

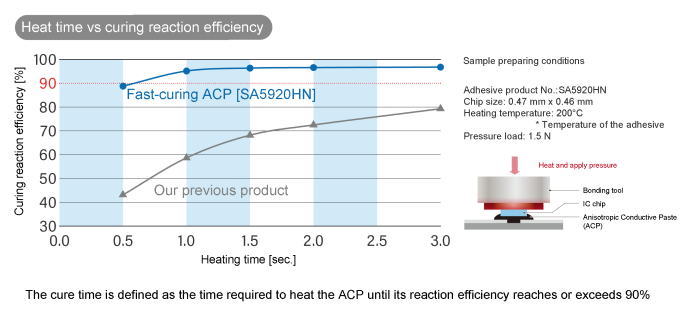

Additionally, Dexerials has successfully developed a fast-curing ACP that achieves full functionality after being heated to 200°C*2 and pressured for a minimum of one second. This new ACP retains the bonding characteristics and bending resistance of our previous product. We anticipate that our fast-curing ACP will enhance the productivity of RFID tags, reduce manufacturing costs, and better meet demands, thereby expanding RFID applications to many other industries.

*2 Temperature of the adhesive

Dexerials has been utilizing our ACP to assist in introducing RFID tags across a broad range of fields. Furthermore, our fast-curing ACP has the additional benefit of being able to cure time of 15 or more seconds. If you are interested in ACP with both fast-cure and low-temperature-cure properties, please feel free to contact us. We offer innovative material technologies to support your business and help build a better future.

- SHARE

Back to top

Back to top  Contact us

Contact us