- Bonding Products

Technology for Epoxy Adhesives That Harden with UV Light and Heat

Contents

The excellent properties of UV-curable adhesives

When you are in a dental clinic, the dentist may fill the cavity with a soft resin paste and then activate a device in your mouth with a click to harden it almost instantly. This device emits ultraviolet light to trigger a chemical reaction in the soft resin, hardening it quickly.

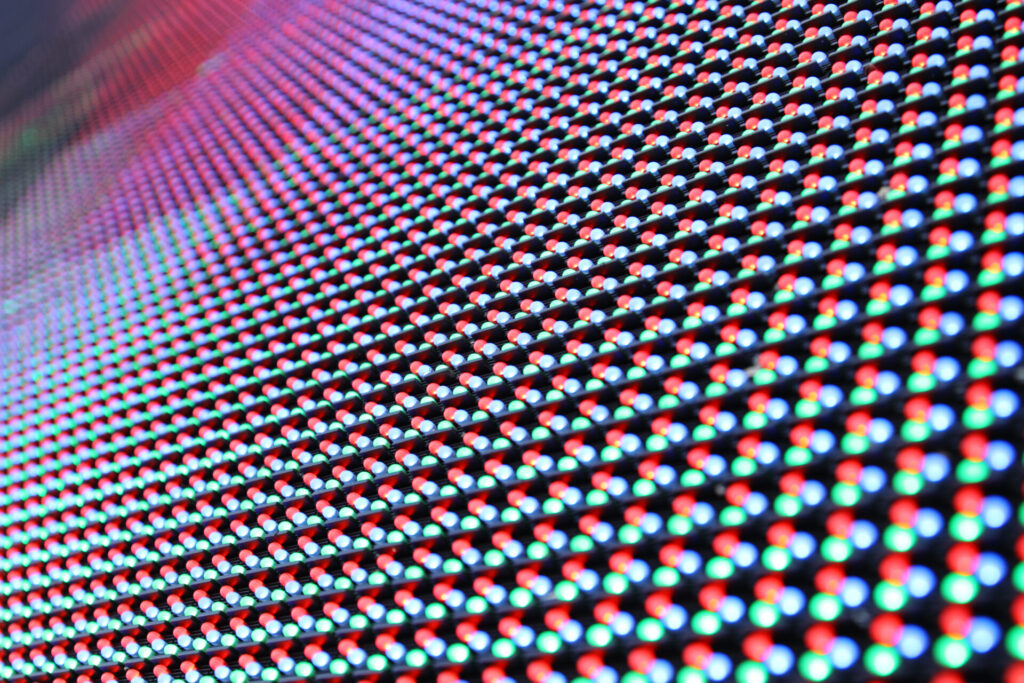

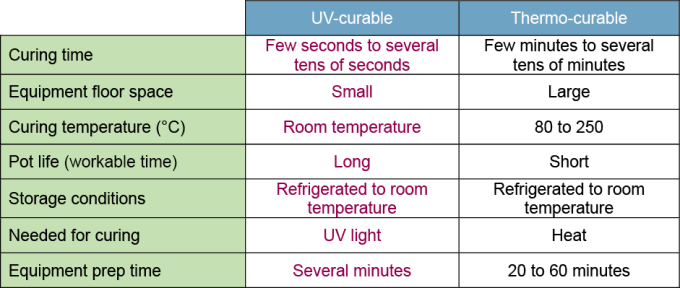

The UV-curable adhesives developed by Dexerials work along a principle similar to the dentist’s resin—they harden when exposed to UV light and bond parts together. There are other kinds of adhesives, such as those that harden when exposed to heat, but UV-curable adhesives have the following eight advantages:

- Fast curing: Adhesion is possible in as little as several seconds. These adhesives offer dramatically shorter curing time compared to thermo-curable adhesives that require exposure to heat for a few minutes to several tens of minutes.

- Low damage: They do not require heat, making them usable with adherence to low heat resistance, such as plastics, vinyl, and paper.

- Space-efficient: The required equipment, such as UV lamps, is generally small. Large furnaces used for heating are unnecessary.

- Low odor: Organic solvents are not used, resulting in a better working environment with less risk of harmful gases, smoke, or water pollution than solvent-based adhesives.

- Safety: Using light instead of heat for processing increases worker safety.

- Low processing cost: Using long-life LED UV light sources results in lower running costs.

- Localized curing: Enables spot adhesion by applying UV light to a small area. It makes adhesion possible even on objects with low heat resistance.

- High abrasion resistance: It is possible to apply finishes to the surface of the adhesive, such as mirror finishes and metallic gloss.

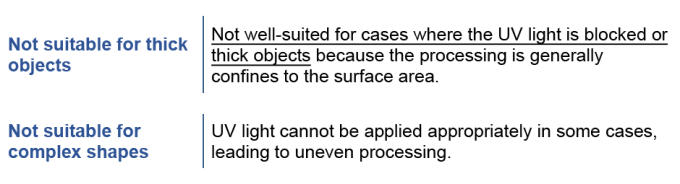

On the other hand, UV-curable adhesives also have disadvantages. Because parts must be exposed to UV light to harden them, they are unsuitable for thick objects or objects with complex shapes. Despite this, due to the advantages above, UV-curable adhesives have seen widespread industrial use in recent years, particularly in securing parts for precision equipment.

Advantages and disadvantages of acrylic (radical polymerization) and epoxy (cationic polymerization) adhesives

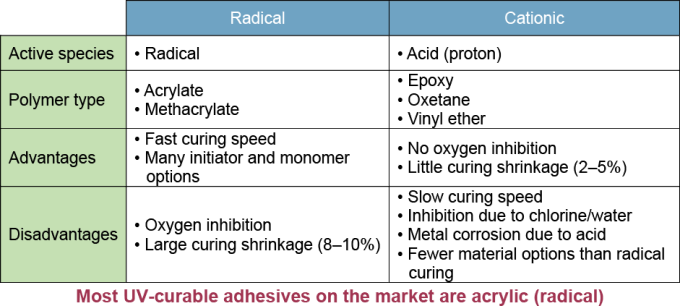

As we examine UV-curable adhesives more closely, we can divide them into two types based on the curing mechanism. One is acrylic adhesives, which harden through a radical polymerization reaction. The other is epoxy adhesives, which harden through a cationic polymerization reaction.

In both cases, energy from the UV light activates the monomers in the unhardened adhesive and begins a chain reaction resulting in polymers.

The following table summarizes the properties of each adhesive type.

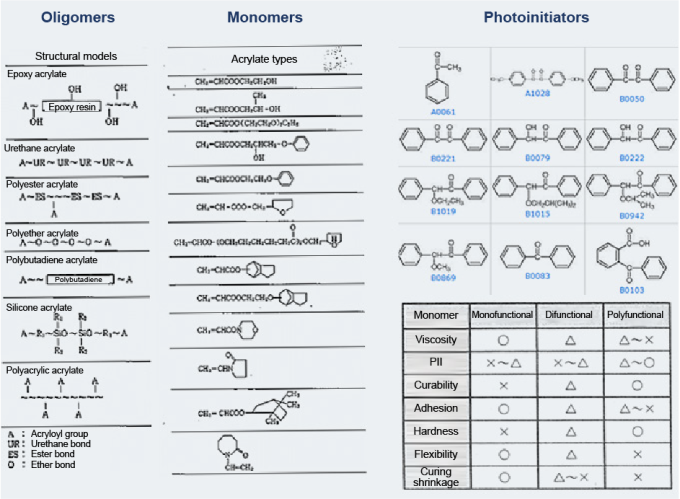

Most UV-curable adhesives currently on the market are of the acrylic (radical) type. This is because of the wide variety of options available for initiators that begin the chain reaction and materials for the monomers that are the primary ingredient for the adhesive, as shown in the table above. Acrylic adhesives also offer freedom in design due to greater adhesive viscosity and workability when added materials such as urethane.

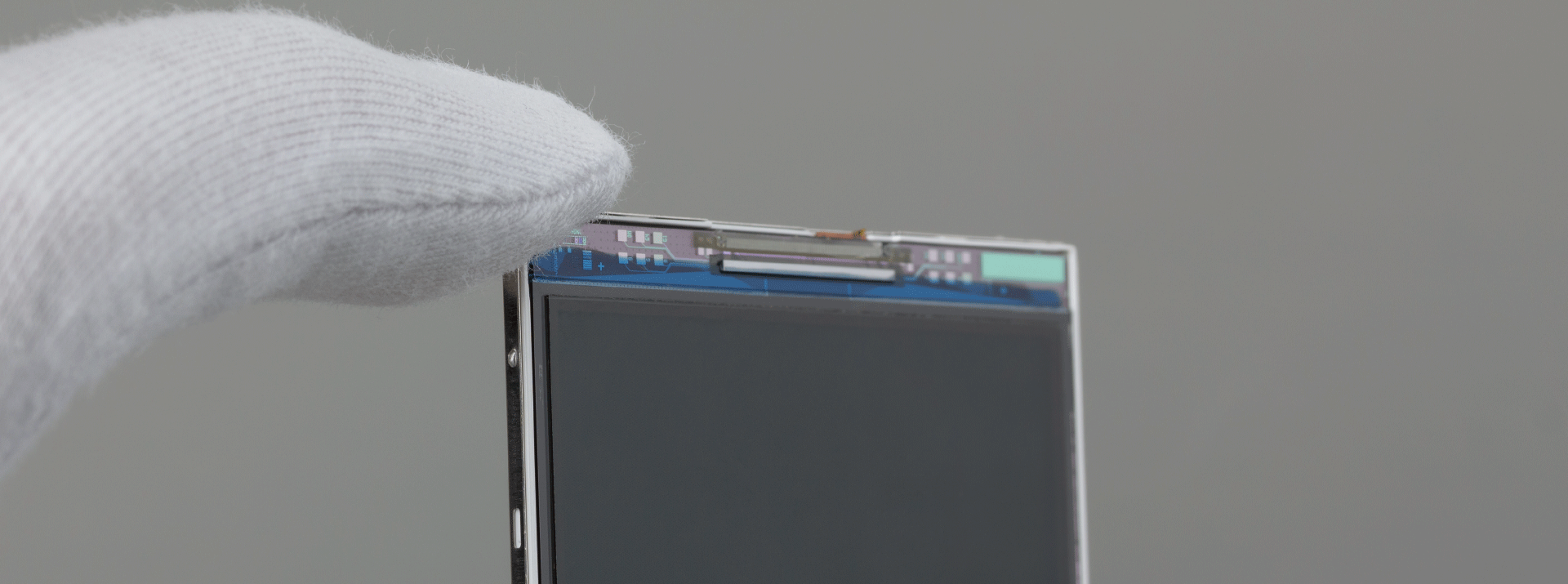

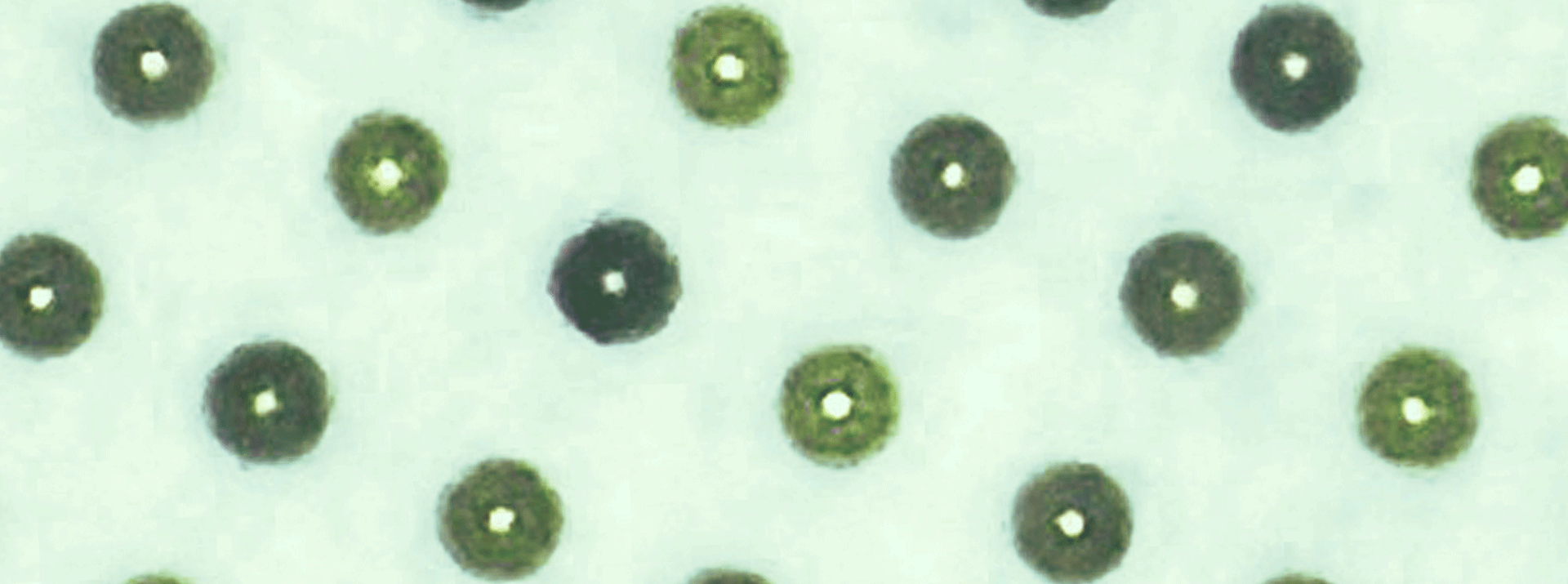

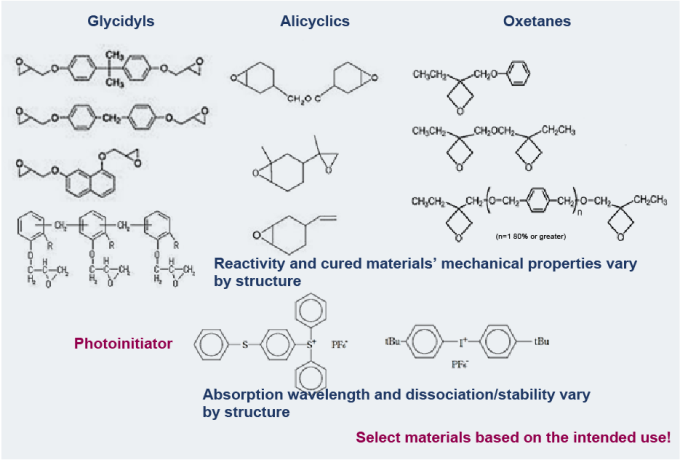

While epoxy (cationic) UV-curable adhesives do not offer as many material options as acrylics, they feature less shrinkage during curing, which is a significant advantage. With little change in volume during curing, they are well-suited for securing parts that require micron-level precision, such as laser diodes used to read Blu-ray discs.

Optimal epoxy adhesives for parts requiring high precision

Dexerials has been researching and developing epoxy UV-curable adhesives for some time and has developed unique products optimized for various uses. The epoxy UV-curable adhesives developed by Dexerials feature curing speeds similar to acrylic adhesives, as shown in the chart, and extremely rigid physical properties after curing.

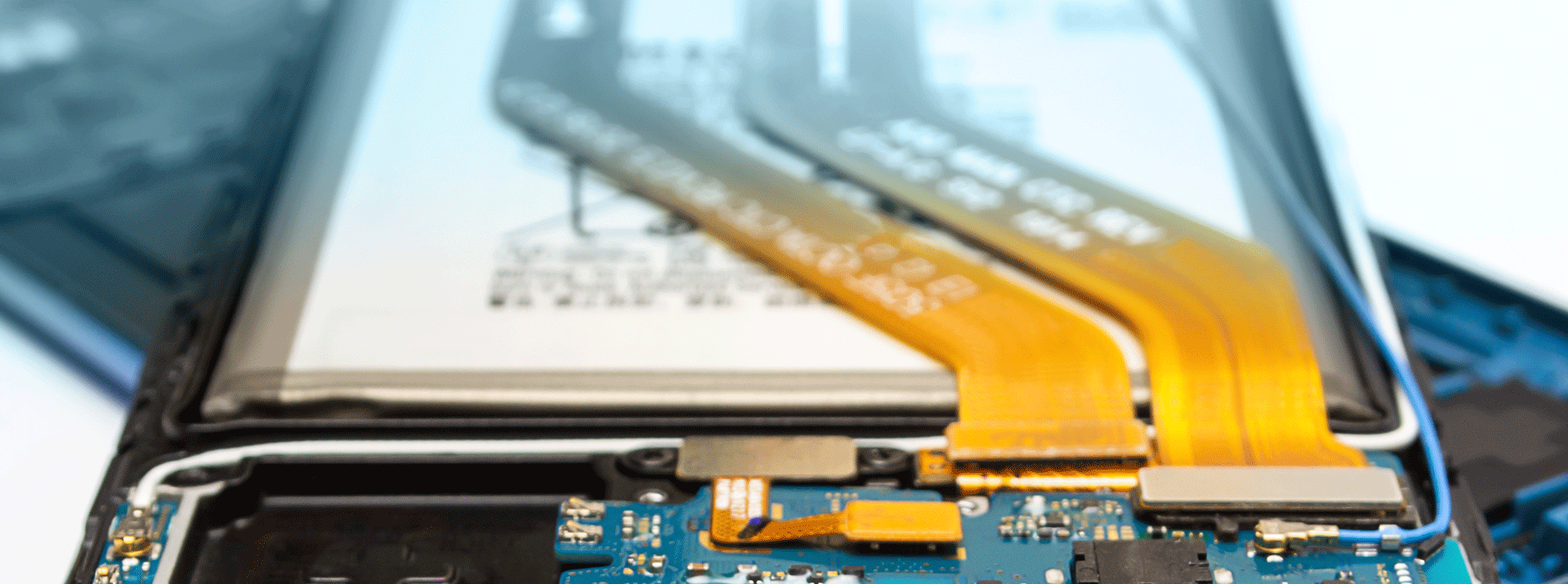

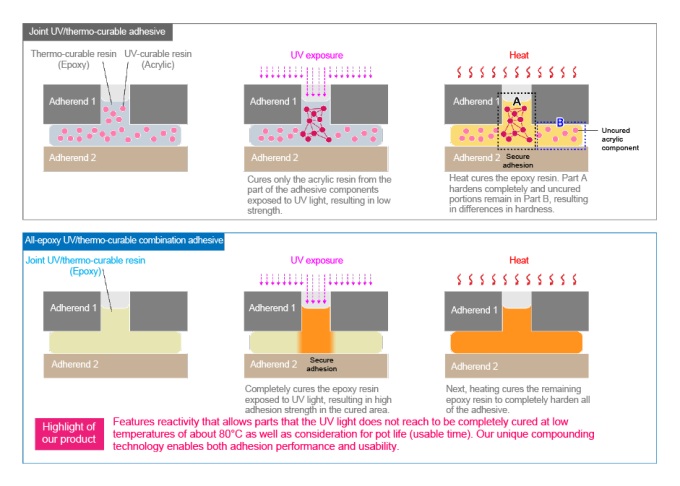

It is possible to apply heat to cure complex shapes or thick materials that UV light cannot reach, and one of Dexerials’ strengths is its ability to make epoxy adhesives that work with both UV light and heat treatment.

As cameras used in smartphones and vehicle sensors have grown smaller in recent years, greater precision is required to secure their internal parts. Dexerials’ epoxy UV-curable adhesives are used in the designs for the core parts of many manufacturers’ newest model products.

There are various factors to consider in adhesion for precision equipment, and Dexerials has built up a wide array of knowledge and technology through its efforts over the years. Please get in touch with us for a consultation if you are facing any questions regarding adhesion.

- SHARE

Back to top

Back to top  Contact us

Contact us